Precision machining is not a new concept. The first machines to do this type of manufacturing were used around WWII, and since then, these machines have played integral parts in numerous manufacturing industries. There are even dedicated precision machining shops that will fabricate custom parts for companies that do not have access to the tools needed to perform this type of machining. This type of manufacturing is ideal for creating precise and intricate parts that need to fit exact product specifications.

Here, we will explore what precision machining is, as well as the many impacts this manufacturing process has on modern manufacturing.

What Is Precision Machining?

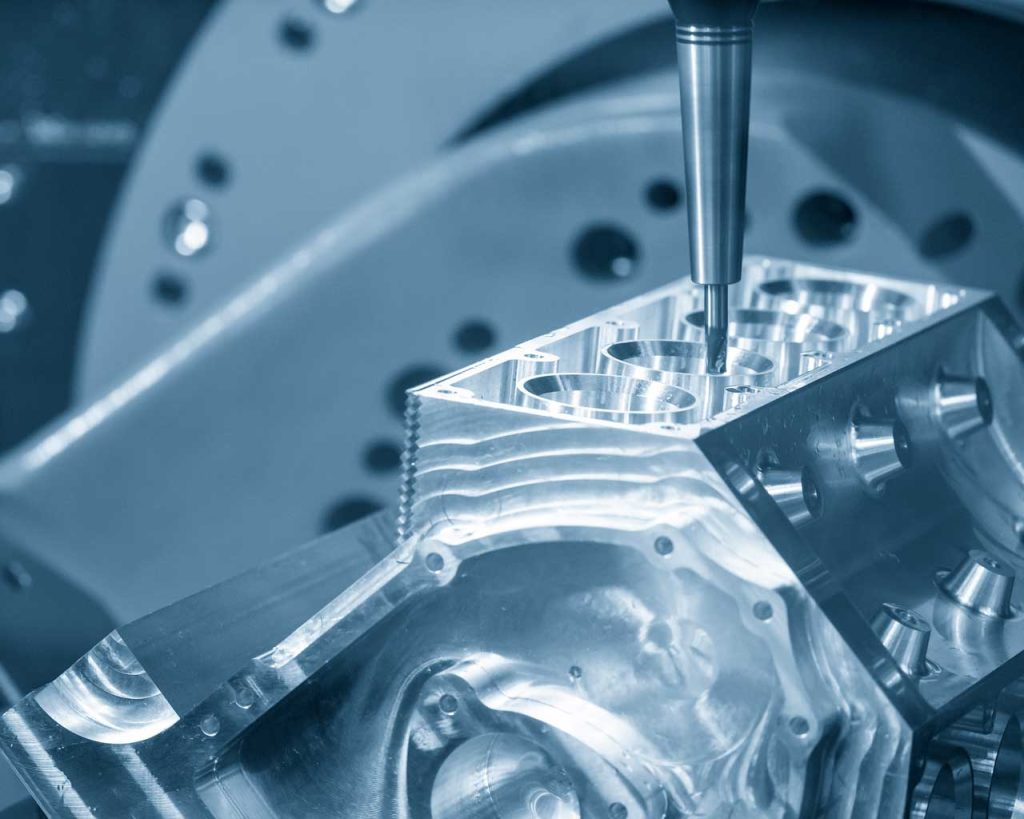

Precision machining, also commonly called CNC (Computer Numerical Control) machining, is used in many industries worldwide today. CNC machines simply refer to tools — such as lathes or mills — that are guided by computers to improve precision and efficiency. CNC machining is a subtractive manufacturing process. This essentially means that this process begins with a larger piece of material and cuts away at it until it forms the shape of the part you want. This ensures that your end result is sturdy because it is crafted from a single piece of material and is not reliant on connections.

This machining technology helps to streamline the manufacturing process and improve efficiency for businesses of all sizes. As technology advances, precision machining also evolves and improves, and over the years, it has become an integral part of many manufacturing processes for companies of all types. Companies in the aerospace, architecture, or defense fields can find these manufacturing tools especially helpful.

The Impact of Precision Machining on Modern Manufacturing

According to market research, by 2025, the global CNC machine market will reach over $100 billion in US dollars. This is a steady increase from the market report of $70 billion in 2018. As more manufacturers adopt these machines, more businesses can reap the benefits of creating more consistent and accurately machined parts for their builds.

Now, you may wonder what exactly the benefits of precision machining are. After all, if you are going to invest in this type of manufacturing technology, you will want to know whether or not your resources could be better spent elsewhere. Realistically, there are countless ways these tools can improve manufacturing processes, but the most notable impacts are as follows.

Improved Safety

Because precision manufacturing typically uses computer numerical control (CNC) machines, manufacturing workers do not have to spend as much time going near potentially dangerous equipment and tools. CNC machines operate based on programmed instructions and use all the tools they need to machine the part created inside their housing. This can be critical for improving the manufacturing process for parts that utilize corrosive materials, high temperatures, or any other dangerous processes.

Maximized Efficiency

Efficient production of machined parts is essential for the continued success of manufacturing teams. There are many types of CNC machines, and they can all dramatically improve production efficiency due to their ability to quickly and accurately produce products to the exact design specifications. With the help of CAD (computer-aided design) and CAM (computer-aided manufacturing), CNC machines can speed up product design, prototyping, and product creation for your manufacturing team.

Improved Accuracy

One of the largest benefits of precision machining tools is their ability to produce the parts you need to be manufactured accurately. Since these tools can be programmed with the exact details and specifications you are looking for. The CNC machine can then accurately create parts using those instructions, so you do not have to worry about human error in measurements or fabrication. These machines typically have a very accurate tolerance range and dramatically reduce the number of errors and material waste.

Uniform Product Production

Another benefit of CNC machines’ ability to produce parts that match their product specifications exactly is the ability to machine identical parts. When parts are produced manually, it is almost impossible to recreate a part identically. But, by using a machine like a CNC mill or lathe, however, you can do exactly this. This allows you to create completely identical parts that you know will fit perfectly into your design.

Improved Capability

One thing that computers are great at is following specific instructions over and over again. This means that when it comes to creating parts that you will need to be re-created, a CNC machine can be exponentially better than machining those parts manually. Manual product production can be useful for very specific or finicky parts that will only be used once, but if you need more than a few parts, a machine is a much more efficient way of creating it. This makes CNC machining extremely efficient for projects requiring a higher volume of parts.

Easily Customizable

Creating intricate and complex parts can be challenging if you manually craft them. But, with the continual advancements in computer designing and manufacturing technology, you can easily fabricate these parts. CAD and CAM software allows your manufacturing teams to prototype and create the exact parts they need. Then, the CNC machine allows them to create these parts quickly and effectively.

Using this type of machine to manufacture your parts allows you to be extremely specific and detailed with your designs. This is especially useful for creating intricate or complex parts that would be hard to manufacture manually or at scale.

Faster Prototyping

Prototyping is often one of the most time-consuming and error-prone processes in manufacturing parts. Since it often requires multiple rounds of tweaking and alternation of designs before you find the right part configuration, a CNC machine can be critical to speeding up this process. CNC machines can easily scan, copy, and reverse-engineer parts you need to create your products.

Because parts made with a CNC machine can be made to precise tolerances, it is much easier to accurately and quickly make realistic prototypes to help influence your decision-making on what parts to use for your build.

Conclusion

As mentioned above, precision machining has become a popular manufacturing process across multiple industries since it can quickly and efficiently create complex and intricate parts quickly and efficiently. But, not everyone can purchase the machines required to do this process in-house. Luckily, even if you do not have a CNC machine of your own, you can still reap the benefits of products created this way by contacting a CNC service provider.

If you are looking for military-grade custom-made machined parts, contact us today at New Age Metal Fabricating (NAMF). We have provided horizontal and vertical CNC milling services for military and aerospace customers for over 60 years and are a leading CNC service provider in New Jersey.