Table of Contents

Custom Machining Services

Custom machining services run a wide range of tools and applications, each with various features and advantages that set one another apart. Usually, for a project one has in mind, there is a type of custom machining that is best suited for it, especially with today’s modern technology that allows for quick, efficient, and precision fabrication.

CNC Machining: An Overview

CNC machining is perhaps the most popular custom machining service out there. Thanks to the efficiency of CAD modeling, CNC machining is one of the fastest methods out there for producing custom parts.

CNC, or computer numerical control, custom machining services are highly precise because they are performed in an automated way, removing the potential for human error. CNC machining is very efficient and capable of processing complex operations without errors or issues, making it a top choice for countless industrial applications.

Additionally, there are several different forms of CNC that you have to choose from, allowing you even more specifications for your project. Many people find that ordering parts via CNC machining is as easy as ordering parts from a catalog or website.

There are several types of custom machining services powered by CNC. A 5-axis CNC machine works with three perpendicular axes and two rotary axes, while a 6-axis machine has three of each.

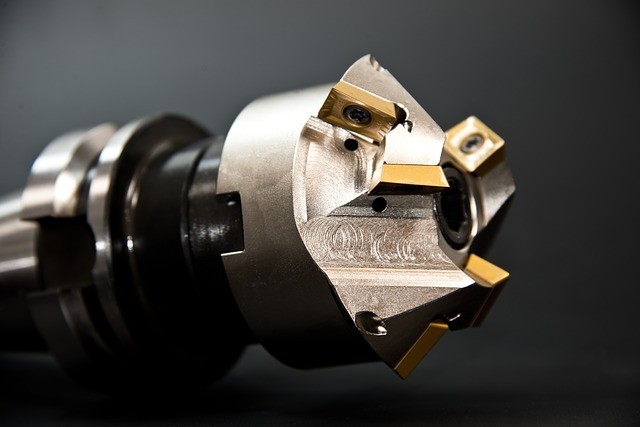

CNC Milling

CNC milling is another very popular type of custom machining service.

With CNC milling, parts are formed from a block of material. The material is milled until the end product is formed. Most people opt for CNC milling when they need to turn and drill metals, though this process can also be used for plastics.

Plastic products that are made via CNC milling are typically left “as-milled”. This means that may show tool parts. Metal products, on the other hand, are less obviously milled.

Milling machines used in traditional machining can be retrofitted for CNC custom machining services, which may be part of why they are so widely used. Modern CNC milling machines are built to be highly efficient, with automated tool changers, auto-feed mechanisms for material changes, and electrical sensors.

Typical applications for CNC milling include prototypes that function as the end product would, jigs and fixtures, and lower volumes of production components.

CNC Lathe and CNC Turning

Another custom machining service that is quite popular is CNC turning and CNC lathe.

CNC lathe is best for those who need to create a 3D shape or mold. As the materials are cut, they turn and are controlled by a computer. This allows for much more accuracy than if one were to use a manual lathe.

CNC turning is similar to CNC lathe, but it involves both marrying lathe and milling. During the process, a metal rod is rotated (made from brass, aluminum, titanium steel, or steel alloy), with the help of a CNC operated cutting tool. This tool removes parts of the metal piece by piece to create the final product. The end product can be left as is or blasted to create a more finished appearance.

As with CNC milling this custom machining service is ideal for functional prototypes, as well as parts ready for end-use, cylindrical parts, and parts that require axial and radial holes, grooves, or slots.

CNC Router

Similar to high-tech manual routers, CNC routers precisely cut and etch complex pieces out of metal sheets.

CNC routers can also be used for composite, plastics, foams, and glass. Typically, CNC routers are best-suited for large-scale custom machining services. CNC routers are used to make wood boards and panels, moldings, furniture, frames, and even musical instruments. Many people also use CNC routers for hobby work as well as for product development, prototyping, and production.

They can also be used to fabricate out of plastics, composites, glass, and foams. Often, CNC routers are used for large scale custom machining services, filling in for shop machines like panel saws and boring machines.

Plasma and Laser Cutting

Plasma cutters offer the ability to cut 2D shapes and molds, while laser cutters work similarly save for the laser in place of a plasma torch. CNC plasma cutters use less energy, while laser cutters are less destructive and can be used on other materials like wood and plastic depending on the strength of the laser.

CNC plasma cutting is used particularly in the HVAC industry, helping to increase productivity and output as the machines are used to cut ductwork. This custom machining process also plays a roll in decorative metalwork and signage.

CNC laser cutting and engraving is highly precise and affordable, used in many industries from components for automotive purposes to pieces of electrical items like cell phones. Of course, used for engraving, the CNC laser is ideal for everything from customizing a product with a name or message, to adding barcodes and other practical information to metal and other surfaces.

Custom Machining At NAMF

At New Age Metal Fabricating and New Age Precision Manufacturing, our motto is “If you design it, we will build it.” Our custom machining services and processes are here to give you the durability and precision you need for prototypes and end use products, with our full range of metal fabrication services including laser, punching, forming, welding, chemical conversion coating, and painting. Each project we do is carefully controlled and created in-house, from start to finish. Contact us today for more information or to get started on a project! [cta txt=”Contact Us Today!”]