- The Military Fabrication Lifecycle

- Design Engineering for Military Applications

- Material Selection and Sourcing

- Advanced Manufacturing Processes

- Quality Assurance in Defense Manufacturing

- Certification and Compliance Requirements

- The NAMF Approach to Military Fabrication

- Emerging Trends in Military Fabrication

- The Future of Military Fabrication

- Frequently Asked Questions

Key Takeaways

- Military fabrication requires specialized processes like dip brazing and precision machining to create components that perform flawlessly in extreme conditions.

- Quality assurance in defense manufacturing goes beyond standard practices, with comprehensive testing and documentation throughout the component lifecycle.

- Emerging technologies including digital integration, advanced materials, and AI-enhanced processes are reshaping the future of military fabrication.

Military fabrication stands at the intersection of engineering precision and national security. Every component manufactured for defense applications carries an extraordinary burden of responsibility. When equipment failure isn’t an option, the fabrication process becomes as mission-critical as the systems it produces.

At New Age Metal Fabricating (NAMF), we’ve witnessed firsthand how military fabrication has evolved from conventional manufacturing into a sophisticated discipline that integrates advanced materials, cutting-edge technologies, and rigorous quality standards. This evolution continues to accelerate as defense requirements become increasingly complex.

The stakes in military fabrication couldn’t be higher. Components must perform flawlessly in extreme environments, withstand unprecedented stresses, and maintain operational integrity when lives and mission success depend on it. This reality drives innovation throughout the entire fabrication process.

The Military Fabrication Lifecycle

Military fabrication encompasses a comprehensive process flow from initial concept through deployment. Understanding this lifecycle provides insight into why specialized expertise is essential at every stage.

The process begins with requirement analysis and design engineering. Military specifications define not just dimensions and tolerances but performance parameters under specific operational conditions. These requirements often push the boundaries of conventional manufacturing capabilities.

Material selection follows, requiring profound knowledge of how different metals and composites perform under combat conditions. The aerospace engineering market, currently valued at $910 billion and projected to reach $1.297 trillion by 2033, drives continuous innovation in high-performance materials that balance strength, weight, and durability.

The manufacturing phase leverages multiple fabrication techniques, frequently requiring specialized equipment and expertise. Post-fabrication processes including surface treatments, assembly, and integration complete the physical production.

Quality assurance represents perhaps the most critical phase, with testing protocols that exceed commercial standards by orders of magnitude. Finally, documentation and certification ensure regulatory compliance and traceability throughout the component’s service life.

Design Engineering for Military Applications

Military design engineering begins with a fundamental question: What must this component do, and under what conditions must it perform?

The answer drives a design process that differs significantly from commercial applications. Military components must operate reliably in temperature extremes, withstand shock and vibration, resist corrosion in maritime environments, maintain functionality despite electromagnetic interference, and sometimes survive ballistic impacts.

Modern military design leverages sophisticated CAD/CAM systems that model not just dimensions but performance characteristics. Finite element analysis simulates stress distribution, thermal behavior, and fatigue factors before physical prototyping begins.

Design for manufacturability becomes particularly important in defense applications. Components must not only meet performance requirements but be producible at scale with consistent quality. This demands close collaboration between design engineers and fabrication specialists.

At NAMF, our engineering team works directly with defense contractors to optimize designs for both performance and manufacturability. This collaborative approach identifies potential issues before they reach production, reducing costs and accelerating timelines.

Material Selection and Sourcing

Material selection for military applications involves navigating complex tradeoffs between performance characteristics, availability, and cost. High-strength aluminum alloys, specialized steels, titanium, and advanced composites each offer distinct advantages for specific applications.

Material traceability represents a critical concern. Defense applications require complete documentation of material provenance, with certifications that verify composition, processing methods, and quality testing. This creates a chain of accountability from raw material to finished component.

Sourcing complexity has increased with supply chain vulnerabilities exposed during recent global disruptions. Defense manufacturers increasingly prioritize domestic sourcing and supply chain redundancy to ensure material availability for critical components.

NJ metal fabrication facilities like ours have become critical nodes in these resilient supply chains, providing essential capabilities close to major defense contractors and transportation hubs. This proximity enhances both security and responsiveness.

Material innovation continues to drive performance improvements. Advanced alloys developed specifically for aerospace and defense applications offer unprecedented combinations of strength, weight, and corrosion resistance. These specialized materials often require equally specialized fabrication expertise.

Advanced Manufacturing Processes

Military fabrication employs multiple manufacturing technologies, each offering specific advantages for different component requirements. Precision CNC machining remains fundamental for components requiring tight tolerances and complex geometries.

Dip brazing services, one of our specialties at NAMF, provides exceptional structural integrity for aluminum assemblies. This process creates joints as strong as the parent material, with excellent thermal conductivity and pressure resistance. These characteristics make dip-brazed components ideal for electronics enclosures and heat exchangers in defense applications.

Sheet metal fabrication, another NAMF specialty, combines laser cutting, punching, forming, and welding to create complex structures from flat stock. Advanced forming techniques enable weight reduction while maintaining structural integrity, critical for aerospace applications.

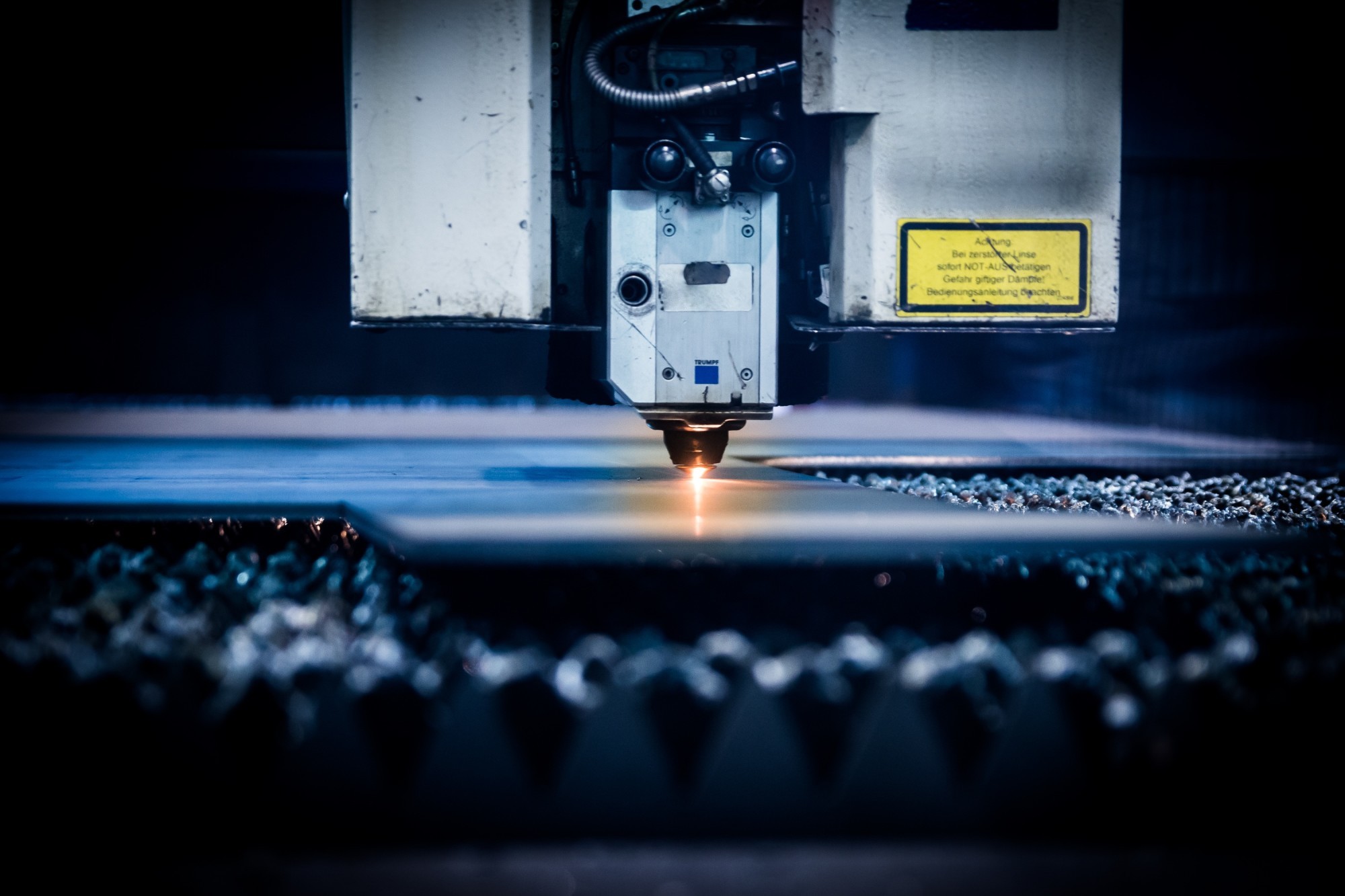

Our laser cutting NJ facility employs state-of-the-art systems that achieve exceptional precision and edge quality. These capabilities prove particularly valuable for components with intricate geometries where traditional machining approaches would be cost-prohibitive or technically challenging.

Brass milling represents another specialized capability within our manufacturing portfolio. The unique properties of brass—including excellent machinability, corrosion resistance, and non-sparking characteristics—make it invaluable for certain defense applications. Our precision milling processes ensure these components meet rigorous dimensional and performance requirements.

Additive manufacturing has emerged as a transformative technology for defense applications. This approach enables production of components with internal geometries impossible to create through traditional methods. The technology particularly excels for low-volume, high-complexity parts that would otherwise require expensive tooling.

Surface treatments provide critical performance enhancements for military components. Chemical conversion coatings, anodizing, and specialized painting systems protect against corrosion, enhance electrical properties, and provide environmental resistance. Working with NADCAP approved platers ensures these critical finishing processes meet aerospace and defense standards.

Quality Assurance in Defense Manufacturing

Quality assurance in military fabrication goes far beyond dimensional inspection. Non-destructive testing (NDT) plays an essential role, allowing thorough examination without compromising component integrity. These techniques detect internal flaws invisible to visual inspection, ensuring components meet stringent structural requirements.

Environmental testing subjects components to simulated operational conditions. Thermal cycling, vibration testing, salt spray exposure, and humidity testing verify performance under extreme conditions. These protocols identify potential failures before components enter service.

First article inspection represents a critical quality milestone. This comprehensive evaluation of the first production unit against all design requirements establishes the manufacturing process baseline. Any deviations must be addressed before full production begins.

Documentation provides the foundation for quality assurance throughout the component lifecycle. Material certifications, process records, inspection results, and test reports create a complete history for each production lot. This documentation supports both regulatory compliance and continuous improvement efforts.

Certification and Compliance Requirements

Military fabrication operates within a complex regulatory framework. AS9100 certification provides the foundation for aerospace quality management systems, while International Traffic in Arms Regulations (ITAR) compliance governs export controls for defense articles and services.

These certifications aren’t merely administrative requirements. They establish systematic approaches to quality, security, and regulatory compliance that protect both manufacturers and their defense customers. Maintaining these certifications requires ongoing investment in systems, training, and external audits.

Cybersecurity has emerged as a critical compliance concern. The Defense Federal Acquisition Regulation Supplement (DFARS) establishes requirements for protecting controlled unclassified information. Manufacturers must implement comprehensive information security programs to maintain eligibility for defense contracts.

At NAMF, we maintain rigorous compliance with all relevant standards and regulations. Our quality management system meets AS9100 requirements, and our ITAR compliance program ensures proper handling of technical data and defense articles.

The NAMF Approach to Military Fabrication

Our approach to military fabrication centers on vertical integration. By controlling the entire manufacturing process from material receipt through finished component delivery, we ensure quality at every stage. This integrated approach eliminates handoffs between suppliers that often introduce delays and quality issues.

Our specialized capabilities in dip brazing services provide unique advantages for defense applications. This process creates aluminum assemblies with exceptional thermal performance and structural integrity, ideal for electronics enclosures and heat exchangers in demanding environments.

Precision CNC machining capabilities complement our fabrication services. Our multi-axis machining centers produce complex geometries with tight tolerances, essential for components that must interface precisely with other systems.

Quality verification employs both traditional inspection methods and advanced techniques, including coordinate measuring machines and non-destructive testing. This comprehensive approach ensures components meet all dimensional and performance requirements before shipment.

Perhaps most importantly, we understand that military fabrication isn’t just about manufacturing processes. It’s about creating components that perform reliably when failure isn’t an option. This mindset informs every aspect of our operation, from material selection through final inspection.

Emerging Trends in Military Fabrication

Digital thread implementation represents one of the most significant trends in military fabrication. This approach creates a continuous digital connection from design through manufacturing, quality assurance, and field service. The resulting data continuity improves both efficiency and quality while enabling more responsive design iterations.

Advanced materials continue to drive performance improvements. High-strength aluminum alloys, titanium-based materials, and metal matrix composites offer unprecedented combinations of strength, weight, and environmental resistance. These materials often require specialized fabrication expertise to realize their full potential.

Automation increasingly enhances both productivity and quality in military fabrication. Robotic welding systems, automated inspection cells, and integrated material handling improve consistency while reducing labor requirements. These technologies become particularly valuable as skilled labor becomes increasingly scarce.

Additive manufacturing continues to mature as a production technology. While initially limited to prototyping applications, metal additive processes now produce qualified components for aerospace and defense systems. This capability enables design optimization impossible with traditional manufacturing methods.

Sustainability has emerged as a priority even in defense manufacturing. Reducing energy consumption, minimizing waste, and eliminating hazardous processes benefit both environmental goals and operational efficiency. These initiatives often align with cost reduction objectives, creating multiple incentives for implementation.

The Future of Military Fabrication

Looking forward, we see several developments that will shape military fabrication in the coming years. Artificial intelligence will increasingly augment human expertise in design optimization, process control, and quality assurance. These technologies will enable more responsive manufacturing while improving both quality and efficiency.

Supply chain resilience will remain a critical focus. Defense manufacturers will continue developing domestic sourcing capabilities and supply chain redundancies to ensure material availability for critical components. This trend creates opportunities for manufacturers with comprehensive in-house capabilities.

Quantum computing may eventually transform both design and manufacturing processes. These systems could enable material simulations and optimization calculations impossible with current computing technologies. The resulting insights could lead to entirely new approaches to component design and fabrication.

At NAMF, we continue investing in capabilities that align with these emerging trends. Our focus remains on delivering precision-engineered components that meet the exacting requirements of defense applications. By combining advanced technologies with deep fabrication expertise, we provide solutions that perform when performance matters most.

Elevate Your Defense Manufacturing Capabilities

Ready to ensure your defense components meet the highest standards of performance and reliability? NAMF’s comprehensive military fabrication capabilities—from design engineering through final inspection—deliver components that perform when failure isn’t an option.