Table of Contents

Precision laser cutting is a leading solution in the engineering and aerospace industries. It’s the modern way to accurately cut through metal and other industrial materials for manufacturing use.

However, laser cutting requires specialized tools and expertise. Accurately and safely slicing through metal with a laser is best left to the experts. Keep reading to learn more about our laser-cutting services in New Jersey.

What is Precision Laser Cutting?

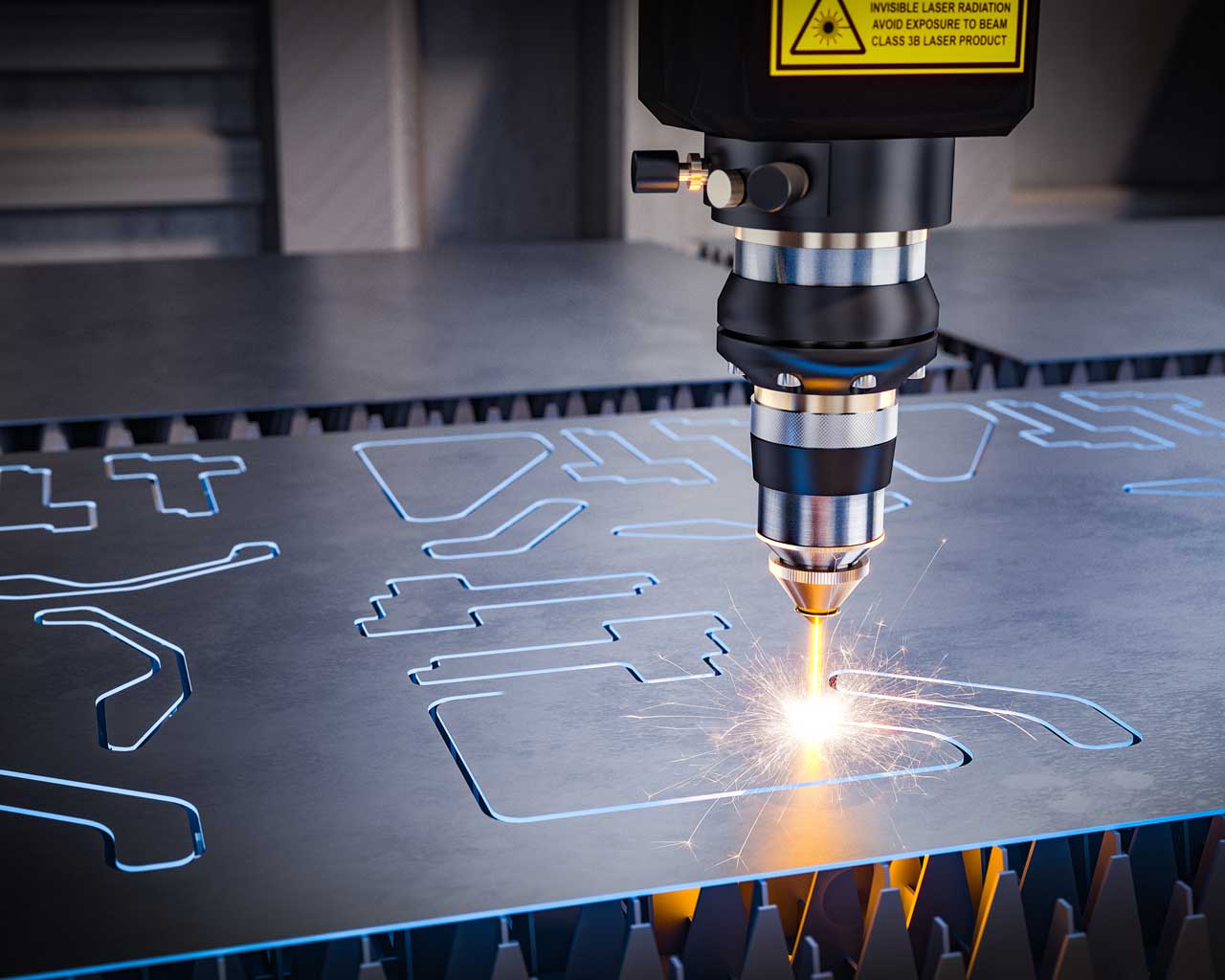

Laser cutting leverages modern technology to slice through metal and other materials. The high-power laser is directed out by optics and vaporizes the material to form a cut edge.

Computer numerical control (CNC) uses optics to direct the laser power and make the desired cut. It’s commonly used for manufacturing applications in a wide variety of industries. Overall, it’s a highly effective way to cut through difficult materials.

Precision Laser Cutting Process

Laser cutting is a sophisticated manufacturing process. It uses high-powered lasers to accurately cut various materials. Here’s an overview of how the process works:

Using CAD software, the technician creates a digital design. The intricate design takes into account the desired dimensions and specifications. Once the design is finalized, it is translated into instructions for the laser-cutting machine.

The laser-cutting machine generates a powerful and focused laser beam. The technician directs the beam onto the material. The intense heat of the laser beam melts, vaporizes, or burns the material along the desired cutting path, this precise and controlled process results in clean, accurate, and high-quality cuts.

The laser cutting process can cut various materials, including metals, plastics, wood, textiles, ceramics, and more. As a non-contact solution, laser cutting does not require physical force. This minimizes the risk of material deformation or damage. This process ensures far more detail than other methods. Use it to make complex geometries, sharp corners, and intricate patterns.

Overall, laser cutting provides manufacturers with unmatched precision, versatility, and efficiency. It’s an indispensable tool in modern manufacturing processes.

Benefits

Laser cutting is a key solution in the engineering, aerospace, and military fields. It’s a reliable way to cut through metal and other materials. Compared to other strategies, laser cutting offers many key advantages.

Accuracy: Precision laser cutting delivers exceptional accuracy. It allows for intricate and precise cuts with minimal tolerances. This level of precision ensures consistent quality and can create complex designs.

Versatility: Laser cutting is highly versatile. Use it to cut a wide range of materials. It can slice through metals, plastics, wood, textiles, ceramics, and more. This versatility makes it suitable for diverse applications across industries.

Speed and Efficiency: Laser cutting is a fast and efficient process. It enables rapid production cycles and reduces lead times. The high cutting speeds and automated operation enhance productivity and throughput.

Minimal Material Waste: Laser cutting minimizes material waste. It creates narrow kerf widths, optimizing material utilization. This reduces costs and contributes to sustainability efforts.

Non-Contact Cutting: Laser cutting is a non-contact process, which means there is no physical force applied to the material. This eliminates the risk of deformation or damage. It ensures clean and precise cuts without altering the material’s properties.

Complex Geometries: Laser cutting creates intricate and complex shapes, including sharp corners, small holes, and detailed patterns. This flexibility opens up new possibilities for design and innovation.

Minimal Post-Processing: Laser-cut edges require minimal post-processing. This reduces the need for additional finishing steps. It saves time and costs in the production process.

Automation Integration: Laser cutting can be easily integrated into automated systems, allowing for high-volume production and increased efficiency. Automation also enhances repeatability and consistency in cutting operations.

Where to Find Precision Laser Cutting Services in NY and NJ?

The New Age Metal Fabricating Company (NAMF) is at the forefront of precision cutting services in NY and NJ. We’re experts in military and aerospace manufacturing.

With our state-of-the-art facilities and cutting-edge technology, we provide efficient laser-cutting services. Our experienced team handles a wide range of materials and complex designs with efficiency.

We’re 100% committed to delivering high-quality results. Our customers count on us for strict quality assurance measures. For reliability and excellence, turn to us for precision laser cutting in NY and NJ.

What to Expect from Professional Precision Laser Cutting Services

When you work with our experienced team, you can expect a seamless and professional experience. Not only that, but we ensure exceptional results. Our highly skilled team of technicians guides you through the entire process. After learning about your exact requirements, we do everything we can to ensure accurate service.

We use industry-leading equipment, like the TruLaser 2030 4 kW Fiber-Optic. It allows us to precisely cut through metal sheets. We can handle materials including aluminum alloys, copper, brass, and stainless steel. With our cost-effective, efficient service, we cut sheets up to 1.5 inches thick!

Before each project, we make sure you understand the materials and cutting techniques. We prioritize quality assurance, guaranteeing consistent, accurate results. We provide expert precision laser cutting as well as valuable advice for machinery maintenance.

At NAMF (New Age Metal Fabricating Company), we go above and beyond to ensure customer satisfaction. We offer complete metal fabrication services, including precision laser cutting and more. Count on us to deliver exceptional outcomes.

Get Precision Laser Cutting Near You

Precision laser cutting services in NY and NJ have revolutionized military and aerospace manufacturing. NAMF, as a leading provider in the field, offers cutting-edge solutions and expertise to meet the demands of these industries.

For all of your precision laser cutting needs in NY and NJ, turn to us. We embrace innovation, collaborate closely with clients, and stay ahead of emerging trends to ensure the best possible services. With over two decades of experience, you can rest assured that your project is in good hands with our team.

If you have any questions about our precision laser cutting services, we’re happy to help. We can provide you with more information and a personalized project quote.

For all of your precision laser cutting needs, turn to our experienced team at NAMF. Contact us today!