The evolution of humankind has always gone hand in hand with innovation. This, in turn, went hand in hand with our ability to shape our design elements.

Of these elements, metals became especially vital to our dreams and ambitions as a species. When we mastered metal manufacturing, we elevated ourselves from straw houses to giant, multi-store structures.

Humans marveled at achieving 35 miles per hour when they first invented the railway.

Now, contributions of high precision machining have enabled us to take to the airs at over 575 miles an hour. We made the world small and thereby accessible.

At New Age Metal Fabrication, we have been part of the journey of metal manufacture since 1979.

With over sixty years of experience in aluminum dip-brazing for the defense and aerospace industries, we have become the go-to source for high precision machining.

Let’s explore this in more depth…

A High Precision Machining Company with 60 Years of Experience

When NAMF was founded, high precision CNC machining was just gaining more recognition worldwide. Computer-Aided Design software entered the market alongside Computer-Aided Machining in 1972.

It was an exciting time to get into metal manufacturing. Including these tools in CNC machining led to considerable developments in the industry.

Though these technologies weren’t fully incorporated into CNC machining until 1976, they soon became industry-standard in the late eighties. Today, CNC machines achieve high speed and high precision like never before.

The process has become faster, more accurate, and more reliable. At New Age Metal Fabrications, we followed along with every innovation. We sought the best ways to provide high-quality metal manufacture at speed.

As a build-to-print manufacturer, we have always used the most advanced and cutting-edge technologies. This goes a long way to ensure we meet our customers’ unique needs and challenges.

High Precision Machining Ready for Take-Off

Precision machining involves various applications at the forefront of modern technology. There are several metal cutting techniques that offer exceptional detail and precision.

All which we employ here at NAMF. Punching metal is cutting holes of different shapes and sizes into sheet metal. The great force then pushes out sheet metal in the specified shape.

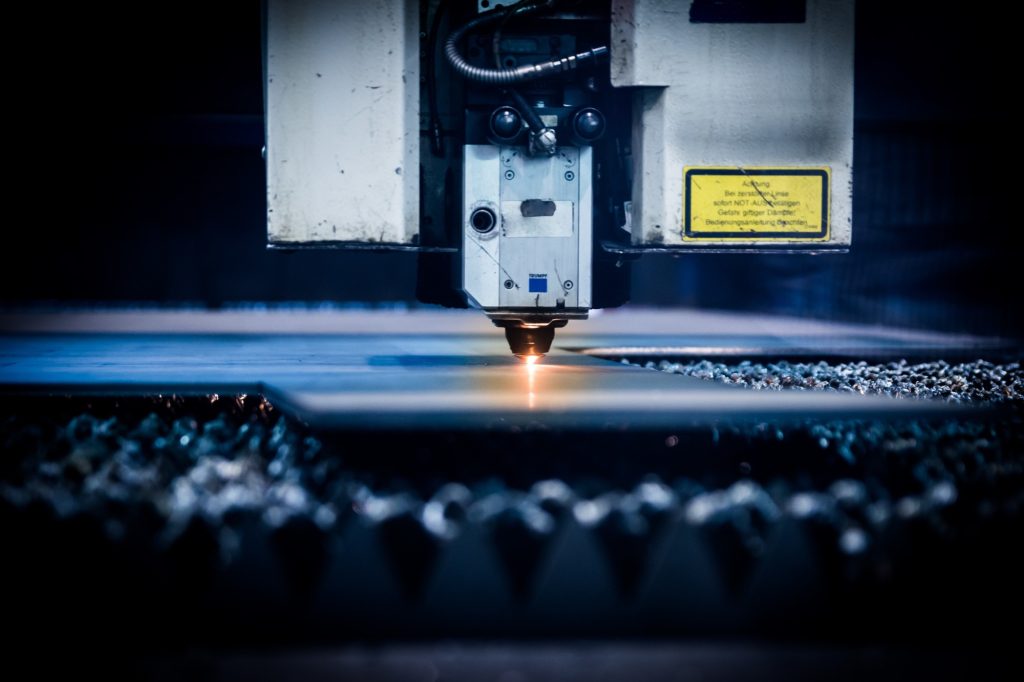

Laser and plasma cutting are cost-effective and clean techniques using a precision metal laser to create different designs in the material as operated by an automated program.

NAPM supplies precision fabricated and dip-brazed products and works with its clients from conception to the final delivery of your products.

What Makes Us Unique

Our experts are with you every step of the journey, with one dedicated contact person for the project. Experience and expertise distinguish us from other manufacturers in the defense and aerospace industries.

We are NADCAP, and NAVSEA approved, as well as AS9100D certified. After sixty years, NAMF has optimized its processes to achieve high speed and accuracy.

That way, we can reduce lead-time for prototyping and ensure your manufacturing needs are met even on tight schedules.

Our 20 CNC milling machines are powered by a robotically controlled PALLETECH system that streamlines this process. Moreover, each of our machines incorporates 120 tools for any specifications.

We can cut any type of metal with:

- Exceptional detailing

- Tabbing and slotting for engineered part designs

- Extreme cost-effectiveness thanks to speed and efficiency

- Consistency and repeatability

- Complex shapes in all accuracy

- Superior edge finishes

To name a few…

Excellence in a Range of Services

No matter your metal fabrication needs, NAMF works alongside our clients to provide time-efficient and problem-free construction no matter the quantity or size of your project.

Reliable Laser Cutting

With Tru laser 2030 4KW Fiber Optic equipment, NAMF can make precise cuts in metal sheets of any thickness. This Laser can cut 5052 and 6061 aluminum alloys, stainless steel, copper, brass, flat sheets, and structural materials.

Our laser cutting process is cost-effective and high-speed. This assures quality results for projects on a tight schedule.

Efficient Punching

We operate Amada CNC punch presses which accommodate sheet sizes up to 50×78. This ensures a quick turnaround for prototyping. In addition, each of our turret punches holds 60 tools, enabling them to punch even complex shapes.

High-Quality Forming

We fabricate metal parts and structures to your specifications. Each of our operations handles four CNC press brakes. These can form a range of angles and radii in aluminum, stainless steel, copper, and brass.

Welding and Military-Grade CNC Milling

Our facilities carry out welding with highly trained experts certified to weld AWS D17.1 and D1.2.

No industries rely on precision and efficiency as much as military, aeronautics, and engineering. We offer versatile and reliable milling with both horizontal and vertical alignment to meet those requirements.

As such, we can provide unmatched flexibility and unlock the benefits of both methods. Never miss out on the accuracy of horizontal mills. Or otherwise, the faster removal rate of vertical mills.

Get Thought-Leaders and Innovators Involved in your Project

Excellence in any industry relies on the steady improvement of processes. This involves optimization over the years. That’s why experience in industries where precision and reliability are essential is imperative.

At NAMF, we have done the work and spent our time learning and improving over decades. This includes evaluating new processes and techniques as they develop. That way, we can stay on the cutting edge of high precision machining.

Today, our experience shows. Our team of designers, project managers, and quality control engineers turn our client’s engineering and design dreams into a reality. Get in touch with us today to discuss your project!