Whether you’re involved in a military or private industry, you should be prepared with EMI shielded enclosures. Regulatory law requires that many fields have strong electronic shielding, but virtually all businesses stand to benefit from the security that EMI protection provides.

What is EMI?

EMI is short for electromagnetic interference, and it refers to the way that external electromagnetic fields can disrupt the normal functioning of electronic devices. Natural phenomena and human activity constantly produce ambient EMI, but EMI can also be employed in targeted attacks.

Potential Sources of EMI

You’re certainly familiar with the experience of turning off your phone before an airplane takes off. This is because cell phones produce trace amounts of EMI, and their use is linked to anomalous events in takeoffs. Any wireless device produces at least some electromagnetic interference. Lightning can cause electromagnetic interference, and interestingly, so can snowstorms or cosmic activity within our solar system. However, manmade EMI from personal devices or weaponized applications is generally more problematic than natural phenomena.

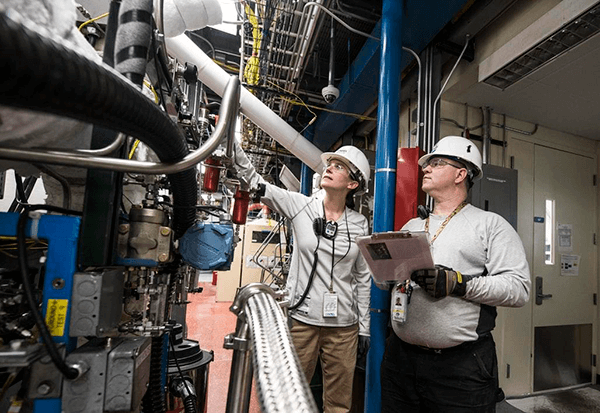

Electromagnetic interference, or EMI, can wreak havoc on electronics of all kinds. It’s something you don’t want to encounter in aerospace. EMI shielding protects electric equipment from interference for safety and better performance.

Ambient sources of EMI include signals and transmissions from televisions, radios, and satellite. Then there are solar magnetic storms, lightning, and the magnetic flux of the Earth itself. There’s utility power grid transmission line interference, transportation radar, telecommunications transmissions, and digital signals contributing, too. Specific industries may encounter problems with EMI such as train signaling systems in railroad applications, or medical equipment sources in the health care industry.

EMI happens because all electronic devices generate electromagnetic waves. If these waves clash, you have a problem on your hands. While many product manufacturers work to reduce EMI at the source through design choices, in many cases that is not quite enough, which is where custom EMI shielded enclosures come in.

There are sometimes intentional electromagnetic disturbances that are made to disrupt or disable equipment such as EMP cannons and high powered pulse devices. This is not a concern for your average citizen but can be a consideration in aerospace and defense industries.

The Anatomy of Custom EMI Shielded Enclosures

An EMI shielded enclosure is an extra layer of protection against EMI interference. EMI shields restrict electromagnetic waves from coming into, or out of, an electronic device.

Creating a custom EMI shielded enclosure is a matter of altering the electronic enclosure to make it act as a barrier against electromagnetic waves. Enclosures are typically best when they are manufactured out of conductive metal material, because that itself adds another element of protection against EMI, reflecting it back.

At New Age we provide EMI shielding through dip brazing, for industries that include military, aerospace, and electronics. Dip brazing not only offers EMI shielding, but it also provides full coverage and improved conductivity, creating strong bonds between all of the parts and pieces in a custom product like an EMI shielded enclosure.

What Fields Benefit From EMI Shielded Enclosures?

Many civilian enterprises should also invest in EMI shielded enclosures, such as hospitals. The dire consequences of electromagnetic interference disrupting life-sustaining equipment don’t bear thinking about. While the stakes aren’t so high in other private industries, any business can suffer serious losses if their products malfunction due to electromagnetic interference. Protect yourself from EMI events by investing in EMI shielded enclosures, which protects your products from latent EMI as well as targeted attacks.

Custom EMI shielding offers the added advantage of efficiency. Instead of trying to cram your product into something that does not quite fit, a custom solution works to protect your product efficiently and effectively, whether you need a one-piece shield, a fence and cover solution, or something entirely custom. Manufacturing is not a one size fits all industry, and your products will perform better when they are fitted with a custom enclosure.

EMI shielding works to save you money. Investing in protection against EMI is setting your business up so that you do not have to fix or replace products that are damaged through electromagnetic waves. It’s a proactive approach that will pay off.

Invest in EMI Shielded Enclosures

Quality electronic protection is more important than ever with the rising levels of ambient EMI and the increasing danger of weaponized electromagnetic interference. If you work in key industries like telecommunications or aerospace, you’ll be familiar with the stringent regulations necessary. That’s why you should partner with a manufacturer that also knows what it takes to deliver reliable, high-quality EMI shielded enclosures.

Partner with New Age Metal Fabrication

Here at New Age Metal Fabrication, we’re experts on all aspects of the EMI shielding process. Whereas other providers rely on contracted work, we handle your parts along every step of the process and ensure that they’re meet and exceed requirements. No matter how large or how small your product is, our custom sheet metal fabrication allows us to create an enclosure that is perfectly dimensioned. We do all of our manufacturing and fabrication work in house, from start to finish, so as we fulfill your parts and product orders, the EMI shielding is just another step along the way.

Everything we do is based on the highest standards, as we are well acquainted with the rigorous requirements of industries like telecommunications and aerospace. We will work with you to understand how your product will be used, what regulations and requirements it needs to meet, and what level of EMI protection you require for the utmost in safety and performance. We can create custom EMI shielded enclosures that meet FCC protection levels, military protection levels, and levels suitable for any type of aerospace application.

For more information about EMI shielding and dip brazing, or to start the custom consultation process, please reach out to a member of our team. We will work closely with your business to ensure that we meet every need. Get in touch with New Age Metal Fabricating at 973.227.9107 or info@namf.com, or connect with New Age Precision Manufacturing at 631.471.4000 or info@napm.com.