Did you know that, although aluminum remains to be one of the most used metals in Aerospace applications, stainless steel is also one of its biggest competitors? Stainless steel is resistant to high-temperature oxidation as well as corrosion. At New Age Metal Fabricating (NAMF), we specialize in stainless steel laser cutting services for the Defense and Aerospace industries.

Our precision machining capabilities are what sets us apart from the competition. We also continue to invest in our state-of-the-art equipment so that we can provide our customers with the best possible products and services.

From military vehicles to aerospace, our team has the experience and expertise necessary to deliver high-quality parts on time and on budget.

Putting it simply, we provide precision machining that other companies cannot match. Keep reading to find out more about our work with the military and within the aerospace industries.

How Can NAMF Help You?

NAMF was founded in 1979 and our initial vision was to provide manufacturing services to the highest standards for the military and aerospace industries, and our vision is still the same. You will notice that we use the most advanced manufacturing technology and techniques. This allows us to meet any challenge that our customers may bring to us.

With 60 years of experience in aluminum dip brazing and the industry itself, you can rest assured that we have the expertise to not only complete your projects but to take the overall solution and output to the next level.

What Are the Advantages You Get From Working With Us?

There are a few advantages that you’ll get from working with a new-age company. First, we are a single-source supplier that manufactures dip brazed products. One of the main reasons that our clients enjoy working with us, is that we provide turnkey solutions for any materials that you need purchasing.

Not only that, if you have a design in mind, we can match that from the construction perspective. Essentially, we are your one-stop-shop for all of your material and building needs. We’re always here to consult and answer questions.

We control every aspect of the manufacturing process, so we take the middleman out of the equation. Allowing us to do the heavy lifting also frees up your time for working on operations and managing the projects that you have on your schedule. Going along with that, you will also have a single point of contact regarding your products and your designs.

We also eliminate additional expenses from the searching process. We do this by handling all aspects of your project. Overall, how it works is that you figure out exactly what you need and get in contact with us. We’ll handle the rest.

Stainless Steel Laser Cutting Services

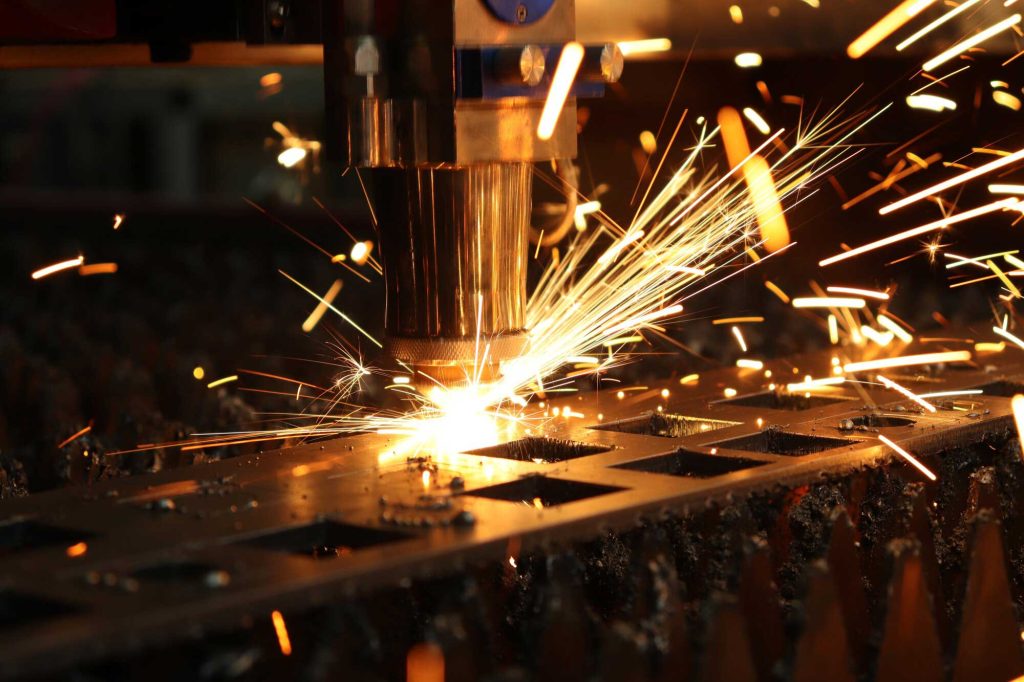

Stainless steel laser cutting is a process that uses a laser to cut through metal. It is often used in the aerospace industry because it produces clean and accurate cuts. Stainless steel is a good material for use in lasers because it does not corrode or tarnish.

The benefits of using stainless steel in laser cutting include:

- Clean and accurate cuts

- Does not corrode or tarnish

- Can be used with a variety of materials

- Low maintenance requirements

- High durability

Regardless of your project, there is a solution for every potential application that stainless steel can be used for. Stainless steel laser cutting is also important for defense systems and the military. It can be used to create parts for tanks, planes, and other weapons.

The material is strong and durable, making it a good material for these applications and others that may not be so obvious.

Laser cutting allows manufacturers like us to quickly and easily create parts from stainless steel sheets. Not to mention that we have the ability to create custom tool designs. This helps reduce manufacturing time and costs.

This material is actually able to maintain its mechanical properties over a wide range of temperatures. Other types of stainless steel also have special properties due to their ability to meet high mechanical demands. One of those specializations is that they are resistant to intergranular attacks that might be caused by a type of chromium precipitation.

What to Know About Stainless Steel Laser Cutting

Here is a bit of advice about stainless steel laser cutting. When it comes to stainless steel laser cutting tips, there are a few things that companies should keep in mind.

First, it’s important to select the right grade of stainless steel for the job. Not all grades are suitable for laser cutting, so it’s important to choose one that is.

Additionally, it’s important to calculate the correct power and speed settings for the job. This will ensure that the material is cut cleanly and accurately.

It’s also imperative to take into account the fact that stainless steel is a heat-sensitive material. Too much heat can damage it, so it’s important to use a cooling system to keep the temperature under control.

To alleviate the need to figure out the logistics and heat to cooling ratio, defense and aerospace organizations can count on NAMF to simplify the process.

Time to Get Started Bringing Your Designs and Needs to Life

Now you know all about stainless steel laser cutting services. You also know how NAMF makes a significant difference in the industry when compared to similar companies.

We work to provide our customers with high-quality materials and services: construction built with cutting-edge technology, efficient turnaround times, and 24/7 365 days a year support.

If you are looking for a reliable supplier of stainless steel laser cutting services, contact us today. We have over 60 years of experience in this field and can provide you with high-quality products that meet your needs.

Click here to learn more about stainless steel laser cutting. Or, contact us today to discuss your specific needs. We look forward to hearing from you!