- The CNC Dominance Nobody Questioned

- Defense and Aerospace Drive the Revolution

- How Is AI Integration Changing Everything?

- The North American Manufacturing Renaissance

- Precise Machining and Manufacturing Excellence Through Advanced Tolerances

- Material Science Meets Manufacturing Innovation

- What Strategic Positioning Do Market Leaders Need?

- Why Is the Competitive Landscape Shifting?

- The Quality Imperative

- Market Consolidation and Opportunity

- Frequently Asked Questions

Key Takeaways

- The precision machining market is growing fast at 7.8% per year. AI technology now cuts programming time from 16 minutes to just seconds.

- Defense and aerospace companies are driving this growth. They need parts made to extremely tight measurements and tough housings for harsh conditions.

- The market is changing to favor companies with complete services, quality certifications, and smart positioning in high-risk industries.

The numbers tell a story most manufacturers missed. While companies talked about small improvements, the precision machining market exploded. It grew from $107.06 billion in 2023 to a projected $180.25 billion by 2030. That’s 7.8% growth each year in an industry many thought was mature.

We’re watching something bigger than market growth.

The CNC Dominance Nobody Questioned

CNC operations control 78.5% of the global precision machining market. This control seemed unbreakable until artificial intelligence joined the game. Old programming methods needed 16 minutes to create complex toolpaths. AI cuts that to seconds. Seconds.

This means more than just working faster. We’re seeing a complete change in how precise machining and manufacturing processes get done, programmed, and sent to market.

Defense and Aerospace Drive the Revolution

The aerospace and defense sectors aren’t just joining this growth. They’re leading it.

Modern military systems need parts with measurements so small they’re measured in microns. Aircraft parts need materials that didn’t exist ten years ago. Turbine blades need shapes that old machining methods couldn’t make. These needs pushed precision machining past old limits.

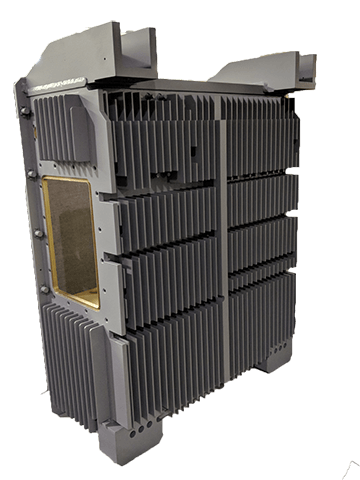

At New Age Metal Fabricating, we’ve seen this change firsthand since 1979. Our two facilities in Fairfield, NJ, and Ronkonkoma, NY, handle increasingly complex specs from defense contractors. They require tough housings that can survive extreme conditions. The precision needs to keep growing.

How Is AI Integration Changing Everything?

Artificial intelligence changed precision machining from reactive to predictive manufacturing.

Quality control systems powered by AI cut defect rates by up to 50%. Programming time drops from minutes to seconds. Predictive maintenance stops critical failures before they happen.

These advances matter most in high-stakes jobs where failure isn’t an option.

Our aerospace clients work in environments where one bad part can ruin entire missions. This backup becomes a competitive edge.

The North American Manufacturing Renaissance

North America became the top region for precision machining growth. Advanced aerospace, defense, and automotive industries cluster here. This creates demand for increasingly complex parts. This geographic focus helps manufacturers with established local presence and proven track records.

We’ve used our 45-year history and two-facility operations to serve this growing market. Our in-house abilities include dip brazing, CNC machining, and precision metal fabrication under one roof. Single-source suppliers become more important as projects get more complex.

Precise Machining and Manufacturing Excellence Through Advanced Tolerances

Modern precision machining reaches tolerances that seemed impossible five years ago. Different types of dimensional limits now reach microscopic specifications.

This ability expansion created new options for product design and function.

Defense applications especially benefit from these advances. Tough housings must keep precise dimensions while surviving shock, vibration, and extreme temperatures. Traditional manufacturing methods couldn’t meet these combined needs.

Advanced precision machining makes the impossible routine.

Material Science Meets Manufacturing Innovation

The precision machining revolution goes beyond equipment to materials. Aerospace applications now use exotic alloys, composites, and hybrid materials that need specialized processing techniques.

Our dip brazing abilities show this evolution. Aluminum dip brazing creates joints stronger than the base materials while keeping precise dimensional control. This process enables complex assemblies impossible with traditional joining methods.

Material innovation drives manufacturing innovation in continuous cycles.

What Strategic Positioning Do Market Leaders Need?

Companies succeeding in this changed market share common traits. They invest in advanced equipment, maintain strict quality systems, and develop deep expertise in specific applications.

We’ve positioned ourselves strategically within these trends through targeted investments and capability development.

Our recent focus on 5-axis machining abilities reduces setup operations while improving precision. AS9100D certification ensures compliance with aerospace quality standards. NADCAP accreditation validates our specialized processes.

These credentials become basic requirements for serious defense and aerospace work.

Why Is the Competitive Landscape Shifting?

Market forces favor manufacturers with integrated abilities and proven performance records. Single-source suppliers eliminate coordination complexity while ensuring consistent quality across all manufacturing steps. This trend especially benefits companies serving high-reliability industries where part failure carries severe consequences.

Our approach integrates design collaboration, precision manufacturing, and quality assurance under unified management. Clients receive finished assemblies ready for immediate integration into their production lines.

Streamlined supply chains become competitive weapons.

How Do Advanced Surface Treatments Integrate with Precise Machining and Manufacturing?

The precision machining transformation keeps speeding up. Automation, AI integration, and sustainability requirements will reshape operations over the next decade.

Successful manufacturers anticipate these changes rather than react to them. Advanced surface treatments like alodine coating provide superior corrosion resistance for aerospace components. Meanwhile, chem film coating ensures optimal conductivity and protection.

We’re investing in workforce development, advanced equipment, and process optimization to maintain our technological edge. Our 40,000-square-foot Fairfield facility provides expansion capacity for future growth. Strategic planning becomes more critical as change speeds up.

The Quality Imperative

Quality standards in precision machining reached record levels. Defense and aerospace applications demand zero-defect manufacturing with full tracking and documentation.

These requirements separate serious manufacturers from basic suppliers. As a metal fabrication company, we understand that brass CNC milling requires exceptional precision for mission-critical applications.

Our quality systems include First Article Inspection, statistical process control, and comprehensive documentation. Every part receives individual attention and verification before delivery.

Quality becomes the ultimate differentiator in high-stakes applications.

Market Consolidation and Opportunity

The precision machining market consolidates around capable suppliers with proven track records. Smaller players lacking advanced abilities or quality certifications face increasing pressure. This consolidation creates opportunities for established manufacturers with strategic positioning. Modern applications require EMI shielding solutions integrated with sustainable metals practices for environmental compliance.

Our combination of experience, abilities, and certifications positions us well within this evolving landscape. Long-term client relationships provide stability, while new market segments offer growth potential. Market transformation rewards preparation and strategic thinking.

The precision machining revolution transforms how critical parts get designed, manufactured, and delivered. Companies positioned at the intersection of advanced abilities, proven quality, and strategic market focus will capture the greatest opportunities in this expanding landscape.

The future belongs to manufacturers ready to embrace change while maintaining the fundamental commitment to precision and reliability that defines excellence in this industry.

Ready to Transform Your Manufacturing Capabilities?

Partner with New Age Metal Fabricating to use our 45 years of precision machining expertise and advanced manufacturing abilities. Our integrated approach delivers the quality and reliability your critical applications need.