- The Electromagnetic Environment Has Changed

- Why Aluminum Dominates Defense EMI Shielding

- The Critical Role of Joint Integrity

- Meeting MIL-STD Requirements

- Design Challenges in Defense EMI Shielding

- The NAMF Approach to Defense EMI Shielded Enclosures

- The Future of Defense EMI Shielding

- Frequently Asked Questions

Key Takeaways

- EMI shielded enclosures protect mission-critical defense electronics from electromagnetic interference that can cause system failures and compromise operations.

- Aluminum dip brazing creates continuous, uniform joints that provide superior EMI shielding and structural integrity compared to mechanical fastening or welding.

- Meeting MIL-STD-461 compliance requires integrated design expertise across material selection, joint integrity, grounding strategy, and manufacturing processes.

One electromagnetic pulse separates mission success from catastrophic failure.

In defense and aerospace operations, electronic systems don’t just support the mission. They are the mission. Communication arrays, navigation systems, radar installations, weapons guidance, and data processing equipment all depend on uninterrupted electromagnetic compatibility.

When electromagnetic interference penetrates an enclosure, the consequences cascade rapidly.

Signal degradation leads to data corruption. Data corruption leads to system malfunction. System malfunction leads to mission compromise. In environments where lives depend on electronic reliability, there’s zero tolerance for EMI vulnerability.

The EMI shielding market reflects this urgency. Valued at $7.34 billion in 2024, projections show growth to $9.69 billion by 2029. That’s not gradual expansion driven by routine upgrades.

That’s defense contractors, aerospace manufacturers, and electronics producers racing to solve an escalating problem.

The Electromagnetic Environment Has Changed

Modern military platforms pack dozens of electronic systems into confined spaces. Communication radios operate inches from radar installations. Navigation equipment shares enclosures with computing systems. Power electronics sit adjacent to sensitive receivers.

Each system generates electromagnetic fields. Each system is vulnerable to electromagnetic interference from its neighbors.

Without proper shielding, these systems disrupt each other. A communication radio’s transmission can corrupt a navigation system’s GPS signal. A power supply’s switching frequency can introduce noise into a radar receiver. A computing system’s clock signal can interfere with radio frequency operations.

The problem intensifies as electronics become smaller, faster, and more densely packed.

Higher clock speeds mean higher frequency emissions. Smaller component spacing means stronger electromagnetic coupling. Increased system integration means more potential interference pathways.

Defense contractors face a technical paradox. They need more capability in less space, but that concentration increases electromagnetic vulnerability.

Why Aluminum Dominates Defense EMI Shielding

Material selection determines whether an enclosure protects or fails. For defense and aerospace applications, aluminum has become the dominant choice for specific technical reasons.

- Electromagnetic conductivity matters first. Effective shielding requires materials that conduct electromagnetic energy away from sensitive components. Aluminum provides excellent conductivity at a fraction of copper’s weight and cost.

- Weight constraints drive every defense design. Aircraft, missiles, unmanned systems, and portable electronics all operate under strict weight budgets. Aluminum delivers robust EMI protection without the mass penalty of steel or the cost penalty of exotic alloys.

- Environmental resistance ensures longevity. Defense systems operate in harsh conditions: salt spray, extreme temperatures, humidity, vibration, and shock. Aluminum naturally resists corrosion and oxidation, maintaining shielding effectiveness throughout the system’s operational life.

- Manufacturability enables complex geometries. Defense electronics rarely fit simple rectangular boxes. Aluminum can be extruded, die-cast, or formed into complex shapes that match specific packaging requirements while maintaining electromagnetic integrity.

We’ve worked with aluminum fabrication for defense applications since 1979. The material’s combination of properties makes it uniquely suited for ruggedized enclosures where failure means mission compromise.

The Critical Role of Joint Integrity

Most EMI shielding failures don’t happen in the base material. They happen at the seams.

An enclosure is only as effective as its weakest electromagnetic pathway. Panel joints, access doors, connector interfaces, and assembly seams all create potential points where electromagnetic energy can penetrate.

Traditional mechanical fastening creates inconsistent electrical contact. Bolts and screws compress gaskets, but contact resistance varies across the joint. Over time, vibration loosens fasteners, gaps develop, and shielding effectiveness degrades.

Spot welding provides better electrical continuity but introduces new problems. Heat-affected zones create metallurgical weak points. Welding distortion affects dimensional accuracy. Incomplete penetration leaves gaps in electromagnetic continuity.

Dip brazing solves these problems through a fundamentally different joining approach.

The process immerses the entire assembly in molten salt containing brazing alloy. The alloy flows into every joint through capillary action, creating continuous, uniform bonds along every seam. The result is complete electromagnetic continuity with no gaps, no inconsistent contact points, and no mechanical fasteners to loosen.

For long vertical joints in enclosure fabrication, dip brazing provides advantages no other process can match. The molten salt supports the structure during brazing, preventing distortion. The brazing alloy stays in the joint rather than pooling at low points. The finished assembly has structural integrity and electromagnetic shielding in a single operation.

The electromagnetic conductivity advantage is measurable. Because the brazed joint is aluminum to aluminum through an aluminum-based filler, conductivity remains high across every transition. There are no adhesive layers, no insulating gaskets, and no contact resistance variations.

Meeting MIL-STD Requirements

Defense electronics must meet MIL-STD-461 standards for electromagnetic compatibility. These requirements ensure systems can operate reliably without emitting or being affected by electromagnetic interference.

Compliance testing is rigorous. Enclosures undergo radiated emissions testing to verify they don’t leak electromagnetic energy. They undergo radiated susceptibility testing to verify external fields don’t penetrate. They undergo conducted emissions and susceptibility testing to verify electrical connections don’t provide interference pathways.

Common failure modes reveal design weaknesses. Panel seams that don’t provide adequate shielding cause radiated emissions to exceed limits. Improper grounding creates ground loops that introduce noise. Inadequate connector shielding allows cable penetrations to compromise the enclosure.

Successful MIL-STD compliance requires attention to every detail. Material selection, joint design, grounding strategy, connector selection, and assembly procedures all contribute to final performance.

We’ve developed expertise in designing enclosures that meet these stringent requirements. Our approach integrates electromagnetic considerations from initial concept through final testing, ensuring compliance before production begins.

Design Challenges in Defense EMI Shielding

Creating effective EMI-shielded enclosures for defense applications involves balancing competing requirements.

- Electromagnetic effectiveness comes first. The enclosure must provide sufficient attenuation across the frequency spectrum where the system operates. Low-frequency magnetic fields require different shielding approaches than high-frequency electric fields. Broadband protection demands careful material selection and joint design.

- Thermal management can’t be ignored. Electronics generate heat. That heat must escape without compromising electromagnetic shielding. Ventilation openings, heat sinks, and thermal interfaces all create potential EMI leakage paths. The design must balance thermal and electromagnetic requirements simultaneously.

- Size constraints limit options. Defense systems operate in confined spaces. Enclosure walls can’t be arbitrarily thick. Joint designs must provide shielding effectiveness within tight dimensional envelopes. Every millimeter matters when packaging electronics into missiles, aircraft, or portable systems.

- Environmental protection adds complexity. The enclosure must exclude dust, moisture, and contaminants while maintaining electromagnetic integrity. Seals and gaskets must provide both environmental and electromagnetic barriers. The design must survive shock, vibration, and extreme temperatures without degradation.

- Manufacturability determines feasibility. Complex geometries, tight tolerances, and specialized materials all increase production difficulty. The design must be manufacturable at scale with consistent quality. Cost constraints require balancing performance with practical fabrication methods.

These challenges demand deep expertise in materials science, electromagnetic theory, thermal management, and manufacturing processes. Solutions require integrated thinking rather than isolated optimization of individual requirements.

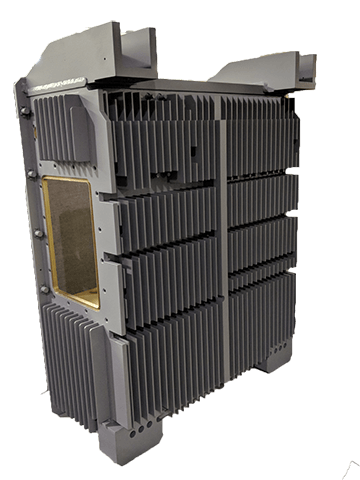

The NAMF Approach to Defense EMI Shielded Enclosures

We’ve built our capabilities around the specific requirements of defense and aerospace EMI shielding. As one of the leading metal fabrication companies specializing in military applications, we understand what’s at stake. Our approach combines specialized processes, rigorous quality control, and collaborative engineering support.

- Full in-house integration eliminates coordination complexity. We perform dip brazing, CNC machining, and precision metal fabrication in our own facilities. Our military fabrication processes ensure every component meets the exacting standards defense contractors require. This means single-source accountability for electromagnetic performance, dimensional accuracy, and delivery schedules. No finger-pointing between multiple vendors when issues arise.

- Dip brazing expertise delivers superior joint integrity. We’ve refined our aluminum dip brazing processes specifically for EMI enclosures. Combined with precision fabricating techniques and military machining capabilities, we deliver enclosures that perform under the most demanding conditions. Our equipment, procedures, and quality controls ensure consistent electromagnetic continuity across every joint. The result is reliable shielding performance that meets MIL-STD testing requirements.

- Dual facility operations provide redundancy. Our Fairfield, NJ and Ronkonkoma, NY locations give defense contractors supply chain resilience. Both facilities feature advanced precision metal cutting equipment and brass CNC milling capabilities for specialized component requirements. If one facility experiences disruption, the other maintains production continuity. For mission-critical components, this redundancy matters.

- Quality certifications demonstrate commitment. We maintain AS9100D and NADCAP accreditations, meeting the aerospace industry’s most demanding quality standards. These aren’t just certificates on the wall. They represent documented processes, regular audits, and continuous improvement systems.

- Engineering collaboration optimizes designs. We work with customers during the design phase to refine enclosures for manufacturability, electromagnetic performance, and cost-effectiveness. Our experience identifying potential issues before production begins saves time and expense.

- ITAR compliance enables defense work. We understand and comply with International Traffic in Arms Regulations, allowing us to work on defense-related projects without regulatory complications.

The defense and aerospace industries demand precision, reliability, and accountability. Components must perform as specified, arrive on schedule, and meet stringent quality requirements. When electromagnetic shielding fails, missions fail.

We’ve spent over four decades developing the expertise, processes, and quality systems defense contractors need. Our focus on aluminum fabrication and dip brazing for ruggedized enclosures positions us to deliver solutions where failure isn’t acceptable.

The Future of Defense EMI Shielding

Electromagnetic challenges will intensify as defense systems evolve. Higher data rates mean higher frequency operations. Increased system integration means denser electromagnetic environments. New threats require more sophisticated electronic countermeasures.

The demand for effective EMI shielding will grow accordingly. Defense contractors need partners who understand electromagnetic compatibility requirements, master specialized manufacturing processes, and maintain the quality systems mission-critical applications demand.

Aluminum will remain the material of choice for defense EMI enclosures. Its combination of electromagnetic properties, weight advantages, environmental resistance, and manufacturability can’t be matched by alternatives. Dip brazing will continue providing the joint integrity electromagnetic shielding requires.

The technical challenges aren’t getting easier. The standards aren’t getting less stringent. The consequences of failure aren’t getting less severe.

Defense contractors need fabrication partners with proven expertise in EMI shielding solutions. Partners who understand MIL-STD requirements. Partners who can deliver consistent quality at production scale. Partners who have the processes, certifications, and track record mission-critical applications require.

We’ve built our company around meeting those requirements. Our capabilities in aluminum fabrication, dip brazing, and precision machining align directly with defense EMI shielding needs. Our quality systems ensure compliance with industry standards. Our experience provides the technical depth complex projects demand.

When electromagnetic interference threatens mission success, proper shielding makes the difference. The enclosure design, material selection, joint integrity, and manufacturing quality all contribute to final performance.

We understand these requirements because we’ve been meeting them for over 40 years. Our expertise in ruggedized enclosures for defense and aerospace applications gives us the technical foundation defense contractors need.

The electromagnetic environment won’t get less challenging. The performance requirements won’t get less demanding. The stakes won’t get lower.

Defense EMI shielding requires specialized expertise, proven processes, and unwavering quality. That’s what we deliver.

Partner With EMI Shielding Experts

When mission success depends on electromagnetic reliability, you need a fabrication partner with proven expertise in EMI-shielded enclosures. Let’s discuss how our capabilities can support your next project.