Table of Contents

When it comes to the Defense and Aerospace industries, there’s no room for error when it comes to precision metal cutting. These industries demand the best in the field for the most advanced technology in a fast-moving world. This is why New Age Metal Fabricating is the leader in precision metal cutting and a go-to name for everyone in heavy metal industries.

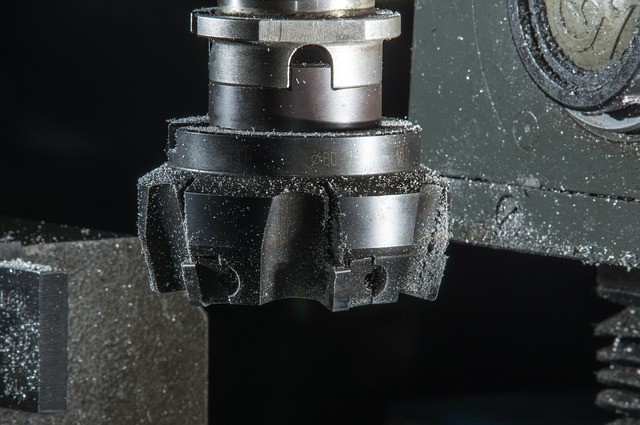

NAMF was founded back in 1979 and has been a long-standing expert in the field of metal fabrication. They have a dedicated staff of hard-working experts that have years of knowledge. Because of this, NAMF has the processes, skills, and experience to provide a high degree of accuracy and quality. When you think about metal fabrication in today’s fast-paced world, the words “CNC machining” should come to mind. At New Age Metal Fabricating and New Age Precision Manufacturing, we know a thing or two about precision metal cutting. As a recognized leader in the Defense and Aerospace industries, NAMF and NAPM are your go-to names for precision metal cutting.

New Age Precision Manufacturing was started more than 60 years ago and has supplied the Defense and Aerospace industries with the best in aluminum dip-brazing. Because of our NADCAP and NAVSEA approvals, the Defense and Aerospace industries regularly turn to us for our expertise.

Precision Metal Cutting Precisely

NAMF is able to cut all types of metal for many different applications. With advancements in technology, metal cutting and fabrication are used to complete many kinds of projects. Industries such as the military, construction, and aerospace have found metal cutting to be an invaluable asset.

There are several techniques used in metal cutting that are very accurate and offer exceptional detail. This includes punching, laser cutting, and plasma cutting. Each has its own perks and individual uses, but here is how to cut metal precisely.

Punching metal involves cutting holes or creating cut-outs of different shapes and sizes into sheet metal. A punch press is then used to apply great force to sheet metal and leave behind a specified shape. This technique can be used on stainless steel, aluminum, copper, and even carbon steel.

Laser and plasma cutting are cost-effective and clean methods of cutting metal. In precision metal laser cutting, a light will cut metal via an automated program that creates different designs and shapes from the material. This has a high level of precision that can produce very complex designs or specific shapes when requested.

These precision metal cutting techniques get implemented with computerized numerical control or CNC. This is done to maintain high accuracy and a low margin of error when cutting metal for a project. Without it, the process of cutting metal would be more difficult and less accurate.

Precision Metal Cutting Explained

At New Age Metal Fabricating, our custom CNC milling services offer you the benefits of the most advanced technology that is available today.

We can cut all types of metal with:

- Consistency and repeatability

- Exceptional detailing

- Complex shapes, handled with incredible accuracy

- Superior edge finishes

- Extreme cost-effectiveness, due to speed and efficiency

- Tabbing and slotting, engineered part designs

In the Defense and Aerospace industries, there is no room for error. Laser technology is also perfectly suited for cutting abrasion-resistant or high-carbon steel. Where these types of hard metals often present challenges, our machining operations will produce clean finishes every time.

CNC Cutting Services and Metal Fabrication Services

Because we are a full-service company, there is no need to look elsewhere for some of your custom metal fabrication to be completed. At New Age Metal Fabricating, we provide complete custom metal fabrication support to our customers.

Precision metal cutting involves more than one process. The combination of several techniques will result in the desired product. At NAMF and NAPM, we are that single-source supplier you have been looking for. We handle precision manufactured, dip-brazed, and painted products. We do it all without subcontractors.

- Laser – We use a TruLaser 2030 4 kW Fiber-Optic laser which can cut 5052, 6061 aluminum alloys, stainless steel, copper and brass. We can cut flat sheets as well as structural materials.

- Punching – both New Age Metal Fabricating and New Age Precision Manufacturing operate Amada CNC punch presses that can accommodate sheet sizes up to 50 x 78. Our turret punches have as many as 60 tools in a turret making them able to create simple to complex shapes.

- Forming – At both our facilities, we use four CNC press brakes. These form a wide range of angles and radii in aluminum, stainless, copper, and brass. Press brakes bend and form metal sheets to predetermined measurements.

- Welding – We carry out welding in both our facilities. Our highly trained welders are certified to weld to AWS D17.1 and AWS D1.2.

- Chemical Conversion Coating – we hold approvals for chemical conversion coating Mil-Spec Mil-DTL 5541. We offer Type 1, classes 1A and 3, and Type II, classes 1A and 3.

- Painting – at NAMF, we offer in-house capabilities for wet paint and electrostatic powder coating. All parts are finished to Mil-Specs and can meet all requirements of Chemical Agent Resistant Coating (CARC).

Why Choose New Age Metal Fabricating?

As precision metal fabricating continues to evolve with technology, NAMF makes every size and shape a high priority. With the use of CNC programming, precision metal cutting is efficient and replaces many of the obsolete processes that have come before. This has made NAMF a valuable partner in the supply chains of many big companies. For the defense and aerospace industries, NAMF is a leader that provides high-quality services that address the needs of companies that need metal cutting for their projects.

Through the decades, metal fabrication continues to change. Technologies and processes that were once used are now deemed obsolete as we have moved on to newer and more advanced operations. This is all to your benefit. From traditional milling techniques to advanced laser cutting, CNC programming has replaced so much of what was done before.

Precision metal cutting is efficient and exact. It has to be. In the Defense and Aerospace industries, we have stepped up into the leadership role. This is due to the ever-expanding capabilities of our highly-trained and dedicated technicians who continue to meet every challenge brought to them.

Every size and shape you need is our priority. We deliver quality parts, on time, for as low a price as possible. Our goal is to provide you with complete manufacturing services because we control every process every step of the way.

Look over our website, and be sure to contact us today to discuss your company’s needs. Whatever you need, we have the answers, even if your innovations haven’t been built yet. Our custom CNC cutting services, including work with painted or dip-brazed finished products, are what we do at New Age Metal Fabricating.

Contact New Age Metal Fabricating to explore different services and products that will help you and your company. We are here to help you.