Table of Contents

Custom CNC Milling At NAMF

In the aerospace industry, precise metal fabrication is in high demand. High-quality manufacturing depends on the reliability and safety of all machinery. It is vital to every aerospace operation that every requirement is met with great precision. Manufacturing, such as custom cnc milling, precision metal cutting, custom chassis fabrication and custom stainless-steel fabrication, become more rigorous with each passing day.

New Age Metal Fabricating (NAMF) and New Age Precision Manufacturing (NAPM) are the leaders in the manufacturing of precision machined parts for the Defense and Aerospace industries. We have been producing the best products that are precisely custom-fabricated for our clients for over half a century.

At NAMF and NAPM, we work with some of the best equipment invented. Our Vertical and Horizontal CNC Machining equipment is the best in the industry. This is how we can achieve the best outcomes in custom CNC milling.

What Is CNC Milling?

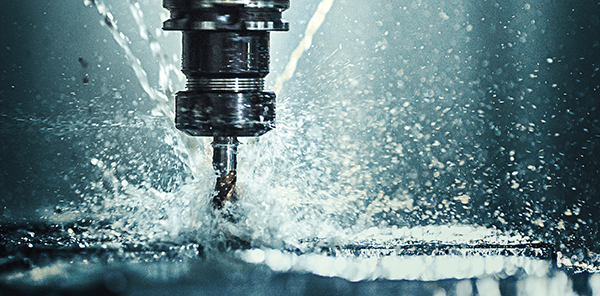

CNC milling, also known as computer numerical control milling, is a machining process. Controls that are computerized and cutting tools—rotating cutting-point tools—begin to remove material from the workpiece. This produces a custom CNC milling part or product. We can machine a wide variety of materials using this method.

Because CNC milling is a mechanical machining process, this means that material is removed from the workpiece utilizing mechanical means. For the best high-quality results at NAMF and NAPM, you won’t find better than custom CNC milling or precision metal cutting.

A CNC mill is controlled by a computer rather than manually input controls. This allows for the highest degree of precision for all of your aerospace products. In the aerospace industry there is no room for error or imperfections – you have come to expect improved precision and decreased imperfections in all machining operations and our CNC milling offers exactly what you need.

Why Choose Custom Stainless-Steel Fabrication?

Stainless-steel fabrication is used to produce a wide variety of products, from custom metal enclosures to chassis fabrication. There are many uses for this material within the aerospace industry.

Because stainless steel has many great qualities, its use is looked on favorably. Since stainless steel is extremely heat-resistant, it can be fabricated for many uses. Secondly, stainless steel has properties perfectly suited to metal fabrication processes. Lastly, stainless-steel stands up to corrosion and rust.

At New Age Metal Fabricating, we use a TruLaser 2030 4 kW Fiber-Optic laser which can cut 5052, 6061 aluminum alloys, stainless steel, copper, and brass. This is a powerful machine with long-standing reliability.

Precision Metal Cutting

We offer various parts – products such as stamped electronic chassis components for the aerospace industry as well as other parts, all of which require precision manufacturing at the highest level. For every part or product, it is imperative that they are cut with precision and to the highest quality for the aerospace industry.

To achieve the best results, we use a method of laser metal cutting. This high-powered laser cuts through, bores, or etches on various metals. At NAMF, laser metal cutting has evolved into a state-of-the-art technology that you will not find elsewhere.

Custom Chassis Fabrication

Sheet metal fabrication services for the aerospace industry are part of what we do every day. 3D CAD files are converted into machine code, and this is what gives the machine its precision in forming the part. Because they are so durable, sheet metal parts make great end-use applications, such as chassis.

Every product we build at New Age Metal Fabricating is created to critical dimensions. We understand the crucial on-demand solutions you are looking for in the aerospace industry. We are here for all of your manufacturing needs.

Key Takeaways:

- Custom CNC milling uses computer-controlled cutting tools to achieve the precision and reliability required for aerospace components, where there’s no room for error.

- NAMF operates 18 vertical milling machines and 2 horizontal machines in a robotically controlled system, making them capable of high volume CNC machining for defense and aerospace industries.

- Their advanced CNC machine shop offers full-service manufacturing solutions from precision metal cutting to custom chassis fabrication, eliminating the need for multiple suppliers.

Ready to Elevate Your Manufacturing?

When precision and reliability are non-negotiable, you need a manufacturing partner with over 50 years of experience in aerospace components. Our state-of-the-art CNC machine shop delivers the custom CNC milling solutions your projects demand, backed by cutting-edge equipment and uncompromising quality standards.