- Can They Actually Handle Your Defense Machining Compliance Requirements?

- Do They Have the Technical Capabilities You Actually Need?

- Can They Scale With Your Production Demands?

- How Do They Handle Quality Control?

- What's Their Track Record With Similar Clients?

- Do They Offer True Partnership or Just Transactions?

- What Happens When You Ask These Questions

- What We Bring to Defense Manufacturing

- Start With Better Questions

- Frequently Asked Questions

Key Takeaways

- Evaluate defense machining partners on compliance depth, not just certifications—ITAR violations can cost up to $1 million per violation and 20 years imprisonment.

- Verify in-house capabilities across dip brazing, CNC machining, and metal fabrication to ensure quality control and avoid extended lead times from outsourcing.

- Assess workforce stability, facility scalability, and supply chain resilience—65% of aerospace companies cite personnel shortages as their primary challenge.

Most defense contractors ask the wrong questions when vetting partners.

They focus on price per unit when they should focus on cost of failure. They check boxes on compliance forms when they should evaluate operational resilience. They tour clean facilities when they should examine workforce depth.

The stakes have never been higher. Over the past decade, small businesses in the defense industrial base shrank by over 40%. The suppliers you can actually trust are becoming rarer.

We’ve spent over four decades manufacturing precision components for defense and aerospace applications. We’ve seen what separates reliable partners from risky ones. The difference shows up in the questions you ask before signing contracts.

Here’s the framework that matters.

Can They Actually Handle Your Defense Machining Compliance Requirements?

Compliance sounds simple until you face the consequences of getting it wrong. ITAR violations can result in fines up to $1,000,000 per violation and up to 20 years imprisonment. Airbus learned this the expensive way with a $3.9 billion penalty in 2020.

But here’s what most contractors miss: compliance isn’t binary.

Some manufacturers check the boxes. Others build compliance into their operational DNA. The difference becomes obvious when you ask the right questions.

- Ask to see their ITAR compliance documentation. Not just certificates. Request their actual processes for controlling technical data, managing visitor access, and training employees on export regulations.

- Request their audit history. How often do they get audited? By whom? What findings came up, and how did they respond? Clean audits matter less than how they handle problems.

- Verify their cybersecurity posture. The CMMC Final Rule takes effect in mid-2025. Manufacturers without robust cybersecurity protocols will lose defense contracts. Ask about their CMMC readiness timeline and current security infrastructure.

Red flags appear when answers get vague. If they can’t walk you through their compliance processes in detail, they probably don’t have them.

Do They Have the Technical Capabilities You Actually Need?

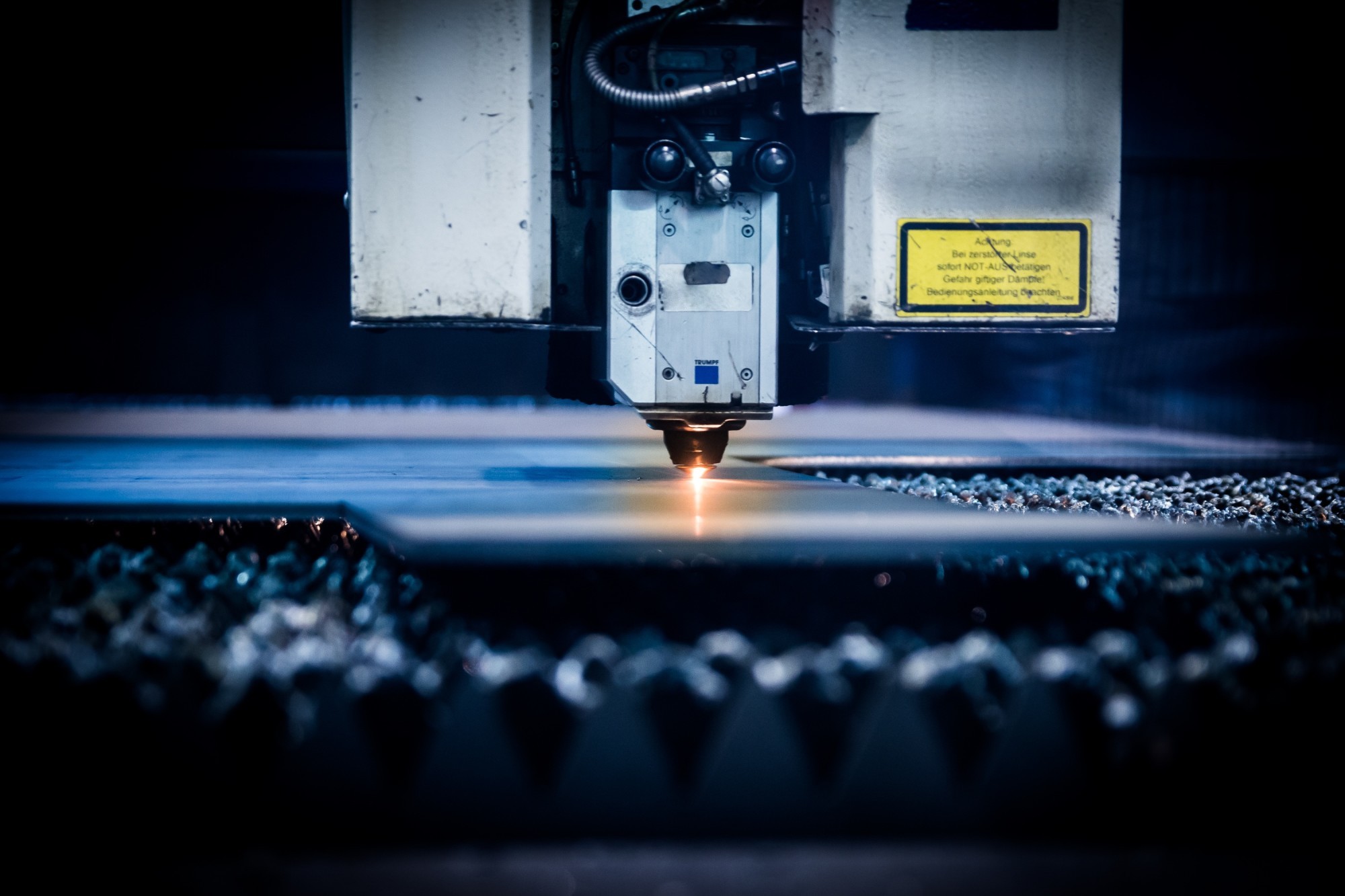

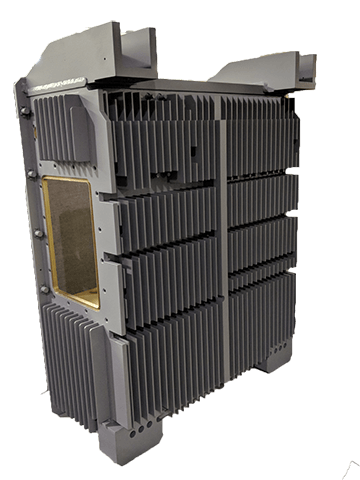

This seems obvious until you realize how many manufacturers oversell their capabilities. The defense and aerospace sectors demand precision that commercial applications don’t require. Tolerances measured in thousandths of an inch, particularly for military machining operations. Materials that perform under extreme conditions. Processes that produce consistent results across thousands of units.

Ask about their in-house capabilities. Do they control every step of production, or do they outsource critical processes? Outsourcing creates quality control gaps and extends lead times.

At NAMF, we maintain aluminum brazing capabilities, CNC machining, and precision metal fabrication all under one roof. This gives us complete control over quality and timing. When something needs adjustment, we make it happen without coordinating across multiple vendors.

Request examples of similar projects. Not just similar industries. Similar technical requirements. If you need ruggedized enclosures that withstand harsh environments, have they built those before? Can they show you samples and performance data?

Verify their equipment capabilities. Advanced CNC machines for turning and milling mean nothing if they’re not maintained properly or operated by skilled technicians. Ask about their equipment maintenance schedules and operator training programs.

Technical capabilities on paper differ from technical capabilities in practice. Push for specifics.

Can They Scale With Your Production Demands?

Defense contracts often start small and scale rapidly. The manufacturer who handles your prototype beautifully might collapse under production volume. Or worse, they might accept orders they can’t fulfill, leaving you scrambling when deadlines approach.

Ask about their production capacity. What’s their current utilization rate? How much additional capacity do they have before quality suffers? What’s their plan for scaling if your orders increase?

Evaluate their facility footprint. Physical space matters. We operate facilities in both Fairfield and Ronkonkoma through our NJ metal fabrication facilities, giving us redundancy and scalability. If one facility hits capacity constraints, we have options.

Examine their supply chain relationships. Do they have reliable access to the materials you need? How do they handle material shortages? Since 2020, component shortages have slowed or stopped production lines across the aerospace sector. Manufacturers with strong supplier relationships weather these disruptions better.

Request workforce stability metrics. High turnover destroys institutional knowledge and quality consistency. Ask about their average employee tenure, training programs, and retention strategies.

The aerospace industry faces significant personnel shortages, with 65% of companies citing workforce challenges as their primary concern. Your manufacturing partner needs a stable, skilled team.

How Do They Handle Quality Control?

Quality control separates professional manufacturers from pretenders. Defense applications leave no room for defects. A failed component doesn’t just cost money. It can compromise missions and endanger lives.

Ask about their quality management system. What certifications do they hold? AS9100, NADCAP, and ISO standards? These aren’t just paperwork. They represent systematic approaches to quality that get audited regularly.

We maintain NADCAP, NAVSEA, and ISO accreditations for military fabrication because our clients demand verifiable quality processes. These certifications mean external auditors regularly verify our methods.

Request their First Article Inspection process. How do they verify that newly produced parts meet all specifications before full production? What documentation do they provide? How do they handle discrepancies?

Examine their inspection capabilities. What measurement equipment do they use? How often is it calibrated? Who performs inspections? Quality control works only when you have the tools and expertise to measure precisely.

Ask about their defect rates and corrective action processes. No manufacturer achieves perfection. What matters is how they identify problems, communicate them, and prevent recurrence.

Quality control isn’t a department. It’s a mindset that permeates every operation.

What’s Their Track Record With Similar Clients?

Past performance predicts future results better than promises.

Request client references from similar industries. Defense and aerospace clients have different expectations than commercial clients. Talk to their existing defense customers about on-time delivery, communication, and problem-solving.

Ask about their longest client relationships. Manufacturers who retain clients for decades do something right. We’ve maintained relationships with major defense contractors for years because we deliver consistent quality and solve problems proactively.

Verify their experience with your specific requirements. If you need dip brazing for aluminum enclosures, have they produced them before? If you need precision machining to MIL-SPEC standards, can they demonstrate that expertise?

Check their reputation in industry networks. Defense manufacturing is a small world. Ask around. What do other contractors say about them? Have they appeared on any Defense Contractor Review Lists with negative indicators?

Experience compounds. Manufacturers with decades in defense work understand the unwritten requirements that trip up newcomers.

Do They Offer True Partnership or Just Transactions?

The best manufacturing relationships go beyond purchase orders.

Ask about their engineering support. Can they help optimize your designs for manufacturability? Do they proactively suggest improvements, or do they just build what you send them? We collaborate with clients on design refinement before production begins. This catches potential issues early when fixes cost pennies instead of thousands.

Evaluate their communication processes. How do they handle questions? How quickly do they respond to concerns? Who’s your point of contact, and do they have decision-making authority?

Ask about their approach to unexpected challenges. Problems happen. Materials arrive late. Specifications need adjustment. How do they handle disruptions? Do they communicate proactively or wait for you to discover issues?

Verify their commitment to continuous improvement. Do they invest in new equipment and training? Are they pursuing additional certifications? Stagnant manufacturers fall behind quickly in industries that demand constant advancement.

Research shows that a multipronged approach to supply chain management that increases focus on data analytics, cross-functional collaboration, and proactive risk assessment can rapidly decrease shortages by more than 25 percent. Your manufacturing partner should bring that collaborative mindset to your relationship.

What Happens When You Ask These Questions

The questions reveal more than answers. Watch how potential partners respond. Do they provide detailed, specific answers? Do they offer to show you documentation? Do they connect you with references without hesitation? Or do they deflect? Provide vague reassurances? Promise to get back to you later? The response pattern tells you everything about how they’ll perform under contract.

The Real Cost of Choosing Wrong

Bad manufacturing partners create cascading problems. Missed deadlines delay your entire production schedule. Quality issues require expensive rework. Compliance failures put contracts at risk. Communication breakdowns waste countless hours on problem-solving that shouldn’t be necessary.

The cheapest bid often becomes the most expensive choice. Defense contracts demand precision, reliability, and accountability. Your manufacturing partner needs to deliver all three consistently. The evaluation process takes time, but it’s time invested in avoiding catastrophic failures later.

What We Bring to Defense Manufacturing

We’ve built our reputation on answering these questions honestly.

Since 1979, we’ve specialized in precision metal fabrication for defense and aerospace applications. Our in-house capabilities span dip brazing, CNC machining, and metal fabrication. We control every step from raw material to finished product.

Our NADCAP, NAVSEA, and ISO certifications verify our quality processes. Our dual facilities provide redundancy and scalability. Our experienced team brings decades of defense manufacturing knowledge. But more than capabilities, we bring a partnership mindset. We collaborate on design optimization. We communicate proactively about challenges. We invest continuously in equipment and training to stay ahead of industry demands.

When you work with us, you get a partner who understands that your success depends on our reliability.

Start With Better Questions

The defense manufacturing landscape keeps changing.

Supplier bases shrink. Compliance requirements tighten. Technical demands increase. The manufacturers who survive and thrive are the ones who build their operations on solid foundations of capability, quality, and integrity. Your job is to identify them before you sign contracts.

Ask the hard questions. Demand specific answers. Verify claims with documentation and references. Tour facilities with a critical eye. Talk to existing clients about real experiences. The right manufacturing partner becomes a competitive advantage. They deliver quality components on time, help you optimize designs, and solve problems before they escalate.

The wrong partner becomes a liability that drains resources and jeopardizes contracts. Choose wisely. The questions we’ve outlined give you a framework for making that choice with confidence.

Ready to evaluate a manufacturing partner who can answer every question on this list? We’re here to show you what four decades of defense manufacturing expertise looks like in practice.

Partner With Proven Defense Machining Experts

NAMF delivers precision metal fabrication, dip brazing, and CNC machining with full ITAR compliance and NADCAP certification. Let’s discuss your project requirements.