Table of Contents

With the advancement of technology, much of the military equipment used by defense industries can perform without human operation. These autonomous and unmanned military vehicles can now enter harsher environments than they were able to in the past. These vehicles can withstand high temperatures and undergo vibration and shock regimes.

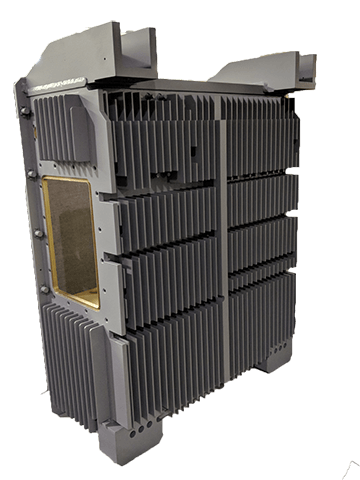

With processor speeds increasing for military computers, so are heat levels. The manufacture of custom ruggedized enclosures is important in helping this equipment and machinery withstand these harsh conditions, as they help prevent electronics such as defense computers from getting smashed to bits as well as overheating. Equipment for military use should be able to withstand harsh conditions such as high/low humidity, extreme heat/cold, high/low pressure, great physical impact, and more.

What Are Custom Ruggedized Enclosures?

Custom ruggedized enclosures are components of a device or piece of machinery that are used to protect an interior mechanism and keep internal parts in place. This is to prevent the device from being damaged by outside debris. Custom ruggedized enclosures are designed to meet rigorous specifications for military use. They help prevent damage caused by dust, water, strong shocks and vibrations, and high temperatures.

Other challenges custom ruggedized enclosures help devices and machinery face include:

- Corrosion and abrasion: Caused by weather and the elements, such as sand or saltwater.

- Minimal size, weight, and power (SWaP): Refers to the size, weight, and power requirements of military operations.

- Acoustic noise reduction: Involves the reduction of environmental and mechanical noise, increasing safe exposure time and improving combat performance.

- Ingress protection: Involves the protection of body parts (i.e., hands and fingers) against dust, accidental contact, and water by mechanical casings and electrical enclosures.

- Electromagnetic interference: Noise or disturbances over a very broad frequency spectrum.

Some custom ruggedized enclosures are made of aluminum, which ensures a simple lightweight, yet strong design. Enclosures usually have either a zinc plating or clear chemical coating for corrosion resistance in harsh environments.

When Should You Use Custom Ruggedized Enclosures?

Custom ruggedized enclosures can be used in various situations.

- Computers: A computer that contains a customized ruggedized enclosure and other protective elements is considered a rugged or ruggedized computer. A ruggedized computer can be left out in a sandstorm, frozen in a blizzard, or sent on a vibrating rocket into space without any detrimental effects. These computers balance processing power with temperature to prevent overheating and malfunction in tough conditions. Despite the need to comply with requirements such as high performance and government-grade security, ruggedized computers can operate under the harshest of conditions.

- Aerospace: Custom ruggedized enclosures protect aerospace vehicles from the elements. Military vehicles are constantly exposed to high altitudes and high atmospheric pressures, which can affect performance and safety.

- Machinery: Enclosures used for machinery such as military vehicles ensure a durable, water-resistant design to meet military specifications and the most stringent demands of military use.

NAMF and NAPM: Leaders in Enclosure Solutions for the Military and Aerospace Industries

At New Age Metal Fabrication and New Age Precision Manufacturing, we fabricate custom ruggedized enclosures from start to finish in-house. We assemble, dip braze, and weld the enclosures. Other fabrication companies have to subcontract their dip-brazing, painting, or chemical film finishing services. Between NAMF and NAPM, we are responsible for every step of the manufacturing process.

Below is an example of the steps we take to manufacture custom ruggedized enclosures:

- CNC Cutting Services: Uses computer programming inputs to control machining tools to manufacture enclosures.

- Assembly: Assembles the enclosures.

- Welding: Welds the materials of the enclosures together.

- Dip Brazing: Joins the pieces of metal together within the enclosure using high heat.

- Heat Treating: Alters the physical appearance and chemical properties of the materials within the enclosures.

- Specially Designed Masking: Applies masking materials to protect the enclosures from certain conditions like high heat and UV rays.

- Engraving: Engraves and marks metals used for the enclosures.

- Chemical Film Coating: Provides a protective coating for enclosures to prevent corrosion and other damage.

At NAMF and NAPM, we have every required certification/registration to do government, military, defense, and aerospace work. We are also an approved vendor for special processes for most of the major defense and aerospace companies, such as BAE Systems. We are approved by BAE to provide dip-brazing, chemical filming, welding, and painting services for custom ruggedized enclosures. Additionally, we have special approval to weld and dip braze according to a special Navy requirement/specification: The Naval Sea Systems Command (NAVSEA).

Key Takeaways:

- Custom ruggedized enclosures protect military and aerospace equipment from harsh conditions including extreme temperatures, vibrations, dust, and water damage.

- These specialized enclosures are essential for computers, aerospace vehicles, and military machinery that operate in challenging environments where standard protection fails.

- NAMF and NAPM provide comprehensive in-house manufacturing services for ruggedized enclosures, eliminating the need for subcontracting unlike other metal fabrication companies.

Ready to Protect Your Critical Equipment with Custom Ruggedized Enclosures?

Don’t let harsh environments compromise your military or aerospace operations. NAMF and NAPM deliver battle-tested ruggedized enclosures manufactured entirely in-house with full government certifications. Our expert team handles everything from rapid machining to chemical film coating, ensuring your equipment meets the strictest military specifications on time and within budget.