- Why Component Marking Matters in Aerospace and Defense

- Technical Challenges of Aerospace Component Marking

- The Integrated Manufacturing Advantage

- Advanced Engraving Technologies for Mission-Critical Applications

- Regulatory Compliance Through Integrated Marking

- Real-World Applications

- The Business Case for Integrated Engraving

- Future Innovations in Industrial Engraving

- Frequently Asked Questions

Key Takeaways

- Industrial engraving services provide permanent identification crucial for aerospace safety and regulatory compliance.

- Integrated manufacturing, combining engraving with fabrication processes ensures consistent quality and reduces production time.

- Advanced engraving technologies maintain component identification integrity even in extreme aerospace environments.

When an aircraft soars at thirty thousand feet, every component must perform flawlessly, its identity and history permanently marked and traceable. In the aerospace and defense industries, the humble engraved marking on a component carries weight far beyond simple identification. These markings serve as the foundation of critical safety, compliance, and security systems that protect lives and ensure mission success. At New Age Metal Fabricating (NAMF), we’ve integrated industrial engraving services into our comprehensive fabrication capabilities precisely because we understand their fundamental importance to our aerospace and defense clients.

Why Component Marking Matters in Aerospace and Defense

The stakes couldn’t be higher. A single misidentified component can compromise an entire system.

The Federal Aviation Administration (FAA) and Department of Defense (DOD) mandate permanent Unique Identification Marks (UID) on critical aerospace components. These marks guarantee authenticity and traceability throughout manufacturing and the entire operational lifecycle of the equipment.

Beyond regulatory compliance, proper component marking enables:

- Lifecycle tracking from manufacture through maintenance

- Authentication of genuine parts versus counterfeits

- Critical maintenance history documentation

- Rapid identification during assembly and maintenance

- Efficient inventory management and logistics

The aerospace industry is particularly sensitive to component identification. Fitting the wrong part can easily lead to catastrophic failure. Every aircraft component requires a unique serial number and part number that follows it from creation to retirement.

Technical Challenges of Aerospace Component Marking

Industrial engraving services for aerospace and defense applications present unique technical challenges that exceed those of standard commercial applications.

First, the environmental demands are extreme. Components face temperature variations from subzero to several hundred degrees, constant vibration, exposure to fuels and fluids, and potentially corrosive environments.

In high-heat environments like aircraft engines, temporary markings simply won’t suffice. Traditional methods such as labeling, inkjet, and RFID tags prove unreliable as they wear off over time or smudge on non-porous surfaces.

Second, the materials themselves present challenges. Aerospace components are manufactured from specialized alloys, composites, and treated metals that require specific marking techniques to maintain structural integrity while ensuring mark durability.

Third, the regulatory requirements are exceptionally stringent. Multiple standards govern aerospace marking, including:

- MIL-STD-130 (Department of Defense marking standard)

- AS9132 (SAE International’s aerospace marking standard)

- ATA/A4A Spec 2000 (Air Transport Association standards)

- EASA Part 21 Subpart Q (European Aviation Safety Agency requirements)

Finally, the marking must maintain perfect readability throughout the component’s entire lifecycle while not compromising its structural integrity or performance in any way.

The Integrated Manufacturing Advantage

Most aerospace and defense manufacturers face a common dilemma. They must source components from multiple vendors, each handling different aspects of the manufacturing process. This fragmentation creates quality control challenges, timeline extensions, and compliance risks.

At NAMF, we’ve taken a fundamentally different approach as a leading metal fabrication company.

Since our founding in 1979, we’ve built our manufacturing philosophy around comprehensive in-house capabilities. Our integrated approach brings together dip brazing, precision machining, metal fabrication, and industrial engraving under one roof.

This integration delivers particular value for component marking and identification.

When engraving is performed by the same team that fabricates the component, several critical advantages emerge:

- Perfect alignment between component specifications and marking requirements

- Elimination of transportation and handling between facilities

- Consistent quality control throughout the entire manufacturing process

- Streamlined compliance documentation

- Reduced lead times and production costs

Mario Costa, our President and CEO since 2017, explains: “We’ve built our entire business model around controlling every step in the manufacturing process. This approach ensures our aerospace and defense clients receive finished products with perfect traceability, ready for immediate introduction into their production lines.”

Advanced Engraving Technologies for Mission-Critical Applications

Our industrial engraving services encompass both traditional and cutting-edge technologies, allowing us to match the marking method precisely to the component requirements.

For aerospace applications, we primarily utilize:

Laser Engraving

Laser marking creates highly durable identifications resistant to wear, corrosion, and fading. This technology ensures that UIDs remain legible throughout the component’s operational life, meeting the strictest requirements for traceability and accountability.

The precision of laser engraving allows for intricate UID markings with exact dimensions and fine details. This precision is essential for maintaining readability and ensuring accurate identification, even in complex aerospace assemblies.

Our laser engraving systems can produce:

- High-contrast alphanumeric text

- 2D Data Matrix codes for machine readability

- Barcodes and QR codes for inventory tracking

- Logo marking and custom identification schemes

Chemical Etching

For certain applications, chemical etching provides superior results. This process creates marks that maintain perfect legibility even after exposure to extreme environments, making it ideal for components that face particularly harsh operating conditions.

Chemical etching is particularly valuable for:

- Extremely hard materials resistant to other marking methods

- Components where surface integrity is paramount

- Applications requiring very deep marking for extended durability

Mechanical Engraving

Traditional mechanical engraving remains valuable for certain aerospace applications, particularly for components where other methods might compromise material properties.

Our mechanical engraving capabilities include:

- Rotary engraving for flat and curved surfaces

- Impact marking for extremely durable identification

- Dot peen marking for components exposed to extreme conditions

Regulatory Compliance Through Integrated Marking

The regulatory environment for aerospace and defense manufacturing grows increasingly complex each year. Component traceability requirements form a critical part of this regulatory framework.

Our integrated approach to industrial engraving services provides significant advantages for regulatory compliance:

First, by maintaining control over the entire manufacturing process, we ensure consistent documentation from raw material to finished component. This unbroken chain of custody simplifies compliance verification.

Second, our familiarity with aerospace and defense standards ensures that all markings meet the specific requirements of MIL-STD-130, AS9132, and other relevant specifications without requiring separate verification.

Third, our quality control processes verify marking legibility and accuracy before components leave our facility, eliminating the compliance risks that occur when components travel between multiple vendors.

Finally, our complete documentation package provides clients with all necessary compliance evidence in a single, coherent format.

Real-World Applications

Our industrial engraving services support a wide range of aerospace and defense applications:

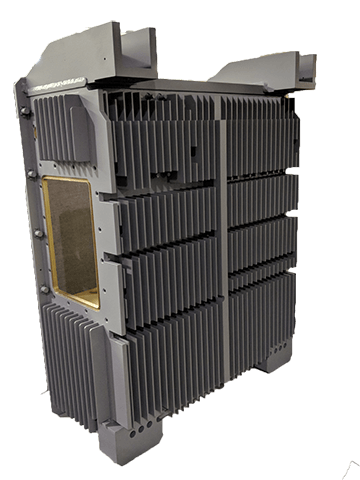

Ruggedized Enclosures

NAMF specializes in dip-brazed aluminum enclosures for defense electronics. These enclosures require precise identification markings that withstand harsh field conditions while maintaining perfect legibility for maintenance and field service.

Our integrated approach ensures that engraving specifications are incorporated from the earliest design stages, eliminating the need for post-production marking that might compromise enclosure integrity.

Aircraft Components

For aircraft components, traceability isn’t just a regulatory requirement—it’s a fundamental safety system. Our precision engraving capabilities ensure that each component carries its complete identification and manufacturing data in a form that remains readable throughout its operational life.

With our CNC aluminum machining expertise, we can produce components that meet the exacting standards of the aerospace industry while incorporating permanent identification markings.

Military Applications

As a trusted military fabrication partner, we understand the unique requirements of defense applications. Our industrial engraving services meet the strict standards for component identification in mission-critical military equipment.

The combination of our chem film coating processes and industrial engraving capabilities ensures that components maintain both their protective finishes and their identification markings even in the harshest operational environments.

Satellite and Space Systems

Space applications present perhaps the most extreme environmental challenges for component marking. Our advanced engraving technologies produce marks that withstand the vacuum, radiation, and temperature extremes of space while maintaining perfect legibility.

The Business Case for Integrated Engraving

Beyond technical advantages, our integrated approach to industrial engraving delivers significant business benefits:

First, it reduces total production time. When components don’t need to travel between facilities for marking, weeks can be eliminated from production schedules. Our rapid machining capabilities further enhance this time advantage.

Second, it reduces costs. Eliminating transportation, additional handling, and duplicate quality control processes creates meaningful cost savings.

Third, it reduces risk. Each transfer between facilities introduces opportunities for damage, loss, or contamination. Our integrated approach eliminates these risks.

Finally, it simplifies project management. With a single point of contact for the entire manufacturing process, our clients avoid the coordination challenges of managing multiple vendors.

Future Innovations in Industrial Engraving

The field of industrial engraving continues to evolve, with new technologies offering enhanced capabilities for aerospace and defense applications. At NAMF, we maintain our technological leadership through continuous investment in advanced marking systems. Current areas of development include:

- Enhanced data density in component marking, allowing more information to be stored directly on the component

- Integration of anti-counterfeiting features into component markings

- Automated verification systems that confirm marking quality during production

- Environmentally optimized marking processes that maintain performance while reducing environmental impact

Elevate Your Aerospace Components with NAMF

Ready to enhance your component traceability while simplifying your manufacturing process? NAMF offers comprehensive industrial engraving services integrated with our full range of metal fabrication capabilities. Our dual manufacturing facilities in Fairfield, NJ and Ronkonkoma, NY provide both capacity and redundancy, ensuring that your production schedules remain on track even during periods of peak demand. Contact us today to discuss your specific engraving and fabrication requirements.