Custom enclosure fabrication is a critical component highly demanded in both the aerospace and defense industries. Expert engineering and tools are required for custom enclosure fabrication products for the client’s requirements. The highly demanded customization service for enclosures is not just for aesthetics, but to keep equipment functioning for the decades ahead. The latest technology and upgrades fuel the aerospace manufacturing industry and its growth. Constant innovation in the industry is required to ensure that all machines and equipment used are of the highest quality and utmost efficiency.

Keep on reading to find the importance of the product, specifically for the aerospace industry.

Aerospace Industry Requirements

As mentioned before, the aerospace industry is a highly dynamic industry that constantly changes. These changes can incorporate better technology, processes, and materials to ensure higher chances of success for the users.

It has been predicted that in the upcoming years, several significant changes will be taking place in the aerospace industry that will include:

- Adoption of smart factory processes to reduce inefficiencies

- Implementation of environmentally sustainable manufacturing processes, specifically in commercial aerospace

- Increase in demand for aerospace products after COVID-19

- Increased safety and compliance efforts

Several accidents and the pandemic have made concerns for safety paramount. In this aspect, custom enclosure fabrications have become the need of the hour for many manufacturers, suppliers, and buyers.

Buyers are also looking for more choices regarding the materials being used today. As new and more efficient materials are being introduced to make aerospace products lighter and more durable, buyers are looking for bespoke customization on their aerospace products that can incorporate newer materials.

What Are Custom Enclosure Fabrications?

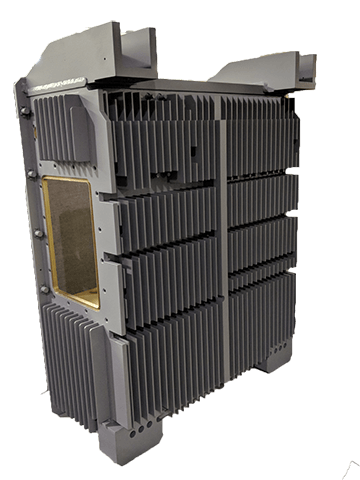

Custom enclosure fabrications are highly demanded by not just the aerospace industry but also by the defense industry. While many people believe that custom enclosure fabrications are merely shells, custom enclosures are much more than that.

Whether you’re looking to protect crucial components of your aerospace equipment or something delicate, custom enclosures can guarantee that these components will never have to be damaged.

Custom enclosure fabrications can be found in various materials, including aluminum, galvanized steel, stainless steel, and other steel variants. They are made to order, ensuring a perfect fit for the component they will be protecting. Depending on your requirements, you can also find various color options to ensure that the custom enclosure integrates seamlessly into your aerospace equipment.

Many aerospace companies opt for aluminum enclosures as they are highly durable and lightweight. Weight is a specific concern in the aerospace industry, so this metal is ideal for many requirements. The metal is also resistant to corrosion and puts less strain on the vehicle during flight, which is crucial.

Benefits of Custom Enclosure Fabrication

Many may think that custom enclosure fabrication is not required for aerospace applications, but that is simply not true. Just like you can’t throw your phone without a screen guard and cover anywhere you please, the same rule applies to aerospace equipment.

Not having the proper protection leads to minor damage like scratches and dents but can ruin the critical functioning of the component. Long-term exposure to elements can render the useless component years before its time and lead to costly replacements as well.

When aerospace machines and devices are constantly exposed to external elements and regular use, they are highly likely to be compromised. To avoid potential criminal attacks from outside the vehicle as well, protection is required. A custom enclosure can help protect against external elements, electromagnetic interference, and more.

The use of custom enclosure fabrication also lessens the noise and vibration originating from the engine, which can be harmful to humans without any buffer. It keeps the engines and other crucial components secured without fail, and because it’s customized to fit your requirements, you don’t have to worry about it falling apart while in use. It also helps protect essential components from corrosion.

Custom enclosure fabrications can also help regulate temperature, especially with components that tend to run hot when used. Ensuring the durability of your components is also crucial, especially in the aerospace industry, where a single component can cost thousands of dollars. You can keep them protected and functional for years without any problems with custom enclosures.

Choosing the Right Enclosure Fabrication For Your Requirements

Choosing the perfect custom enclosure fabrication is essential to providing premium end-to-end protection for your aerospace components. Exposing your delicate aerospace components to unyielding external elements can end up costing you not just money but time as well.

If you’re wondering how to choose the proper enclosure fabrication for your requirements, here are some simple tips you should consider following:

- You need to know your requirements first, comprehensively. What kind of protection are you seeking from the enclosure? Are there any factors that need to be kept in mind when the enclosure is being crafted (e.g., needs to withstand high temperatures)? Only after knowing your requirements, you start the process of getting custom enclosures.

- What are the fabrication options? You must be aware of the different materials that can be utilized to construct a bespoke enclosure for your needs.

- What weight and durability are you looking for? Depending on what the purpose of the enclosure is, you can have different requirements when it comes to the weight of the enclosure.

- Consider the kind of technology used to achieve the custom enclosures for your requirements. Various processes like dip brazing, chemical film finishing, heat treating, and more can be used to achieve the perfect finish for your custom enclosures.

Once you have answered these questions and ascertained what kind of custom enclosure you’re looking for, it’s time to get the process started. The quality of customization that you get on your enclosures can be essential in ensuring the success of your aerospace components. Getting your enclosure customized is the best option when you don’t want to compromise on quality or efficiency.

Key Takeaways

- Custom enclosure fabrication provides essential protection for aerospace components against external elements, electromagnetic interference, and temperature fluctuations.

- Aluminum is the preferred material for aerospace enclosures due to its lightweight properties, corrosion resistance, and ability to reduce strain during flight operations.

- Military fabrication standards require specialized processes like dip brazing and chemical film finishing, ensuring enclosures meet stringent aerospace durability requirements.

Get Premium Custom Enclosure Solutions

Don’t compromise on the safety and longevity of your aerospace equipment. NAMF’s custom enclosure fabrication services deliver precision-engineered solutions that protect against harsh environments, electromagnetic interference, and operational stress. Our military fabrication expertise ensures your components meet the highest industry standards for reliability and performance.