Table of Contents

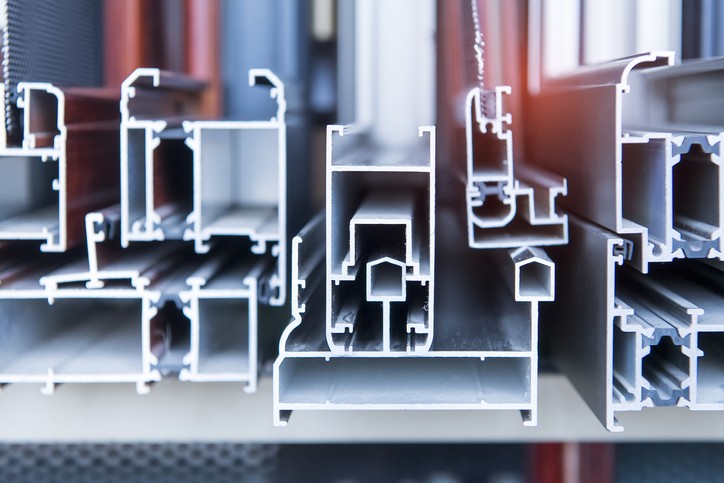

In a world where electronic equipment is crucial across industries, aluminum enclosures are increasingly important for protecting sensitive electronics from external harm. These are structures created from aluminum material built to protect various electronic components and machinery from external threats, like poor environmental conditions or safety hazards in indoor environments.

Aluminum enclosures are being used more frequently as the need for protection for technological components increases, offering a degree of protection unmatched by other solutions. But what are the specific benefits of aluminum enclosures, what are they used for, and what can you expect from these structures in the future? Read more to find out.

The Benefits of Aluminum Enclosures

Aluminum enclosures have several benefits that make them a worthwhile investment in the military and aerospace manufacturing industry.

Below is a breakdown of the specific benefits of aluminum enclosures to consider.

Lightweight

Aluminum enclosures are incredibly lightweight but still provide robust protection to safeguard valuable electronic components. These enclosures are more lightweight than options like steel enclosures, and because the military and aerospace industry often adheres to strict weight requirements, having lightweight solutions is crucial.

The lightweight nature of aluminum makes it a fantastic choice for numerous industrial applications, providing advanced portability to promote fuel efficiency and simplify transportation.

Durability

Another significant advantage of aluminum enclosures is that they are incredibly durable, providing a secure solution to protect valuable electronic components required in military and aerospace manufacturing.

Compared to materials like plastic, aluminum is highly durable and long-lasting, offering structural stability and integrity that’s hard to find with other materials. Aluminum is highly resistant to bending and harsh impacts that would damage other materials. It is one of the best materials available for military and aerospace applications where a strong structure is critical.

Corrosion Resistance

A significant concern in military and aerospace manufacturing is the potential for materials to corrode and lose their durability. Sustainable materials like aluminum eliminate this concern, providing ample corrosion resistance.

Aluminum has a natural oxide layer that, when exposed to air, creates a protective barrier against corrosion. This layer ensures that your aluminum enclosures can withstand corrosive environments that other materials struggle to resist.

For example, aluminum enclosures can withstand harsh conditions like chemical exposures, high winds, sand, and hot temperatures – protecting your equipment from damage, no matter the surroundings.

Applications of Aluminum Enclosures

As you can see, there are numerous benefits to using aluminum enclosures in the military and aerospace industry – but what are the specific applications of these enclosures that make them essential for industrial applications?

Aerospace Components

One of the most common applications for aluminum enclosures is protecting aerospace components from harsh environmental conditions. In the aerospace industry, aluminum enclosures are often used to protect instrumentation, avionics, and communication systems required for safe travel.

Using aluminum enclosures over other protective materials is vital for the aerospace industry because aluminum provides a lightweight solution, helping reduce the aircraft’s overall weight and promoting greater fuel efficiency.

Military and Defense

The numerous benefits of aluminum enclosures make this solution essential for the military and defense industry. Aluminum enclosures serve various purposes, such as protecting electronics and communication equipment vital for efficient commands.

Aluminum enclosures are also used for military aircraft and ground vehicles to protect electronic control systems and critical equipment to keep operations running. Because aluminum enclosures are durable and corrosion-resistant, they protect equipment in dangerous environments.

Aluminum enclosures also have naval applications that make them necessary in the military industry. These enclosures protect electronic systems in naval vessels, like navigation equipment, to prevent exposure to external elements. The enclosures are lightweight, providing portability for military equipment.

Chemical Processing Plants

Aluminum enclosures are highly useful in environments like chemical processing plants because of their durability and corrosion resistance. Chemical processing plants are home to several corrosive elements that can damage the integrity of electronic components, making aluminum enclosures essential to protect equipment from chemicals and corrosive atmospheres.

In chemical processing plants, aluminum enclosures are often used to protect electrical panels, control units, and junction boxes, ensuring systems run smoothly and safely throughout the plant. The aluminum’s durability makes it suitable to withstand harsh conditions long-term.

Telecommunications

Aluminum enclosures are widely used in the telecommunications realm, providing a level of security required to protect electronic equipment from damage.

Within this realm, aluminum enclosures protect networking equipment and communication devices for in-house environments and outdoor applications, protecting cables and other equipment with an unmatched level of durability.

Trends in Aluminum Enclosures

Many trends are emerging as aluminum enclosures become more widely used in manufacturing. As the need for aluminum enclosures expands, this technology will continue evolving to better meet the needs of military and aerospace applications.

Emphasis on Lightweight Design

One of the primary trends in aluminum enclosures is an increased emphasis on lightweight designs to surpass the needs of industries that rely on transportation and portability. Emerging advances in engineering and fabrication processes will help lower the weight of aluminum enclosures without compromising their integrity.

Sustainability

Sustainability is an increasingly important factor across industries, and aluminum enclosure manufacturers are becoming more conscious of the need for environmentally friendly enclosure solutions. As this protective solution evolves, there will be an increased focus on using recycled aluminum materials and creating enclosures following eco-friendly practices.

Enhanced Security

Security concerns present a major threat to many industrial applications, and the need for safe and secure solutions to protect aluminum enclosures is vital. As the market develops, there will be an increased emphasis on providing enhanced protection and security for aluminum enclosures.

More aluminum enclosures will begin focusing on preventing tampering and unauthorized access that could harm electronic equipment and cause problems within an organization. This trend will serve a massive purpose for industries like the military and aerospace realms, where data security and equipment safety are crucial.

Discover Aluminum Enclosures From NAMF

Aluminum enclosures play a critical role in the military and aerospace industry, providing a robust level of protection required to keep electronic equipment safe. From lightweight design to durability and corrosion resistance, aluminum enclosures will continue contributing to industry advancements.

NAMF provides top-grade aluminum enclosures to protect your equipment from external damage. Contact NAMF today to learn more about using aluminum enclosures to protect your business.