Key Takeaways

- Electromagnetic interference poses escalating threats to military, aerospace, and medical systems, with weaponized EMI capabilities now deployed by adversaries and documented equipment failures resulting in operational disruptions and fatalities.

- Effective EMI shielded enclosures require conductive materials, seamless manufacturing processes like dip brazing that eliminate electromagnetic leakage paths, and custom engineering tailored to specific operational environments.

- Proactive investment in precision-engineered EMI protection prevents catastrophic mission failures and costly field replacements while ensuring compliance with MIL-SPEC standards and regulatory requirements.

Five Blackhawk helicopters fell from the sky in the late 1980s. The culprit wasn’t mechanical failure. It was electromagnetic interference from radar transmitters disrupting flight control systems. Documented helicopter crashes proved EMI wasn’t theoretical risk. It was operational reality. That was four decades ago.

Today, the threat has evolved from accidental interference to weaponized electromagnetic warfare. A November 2024 congressional report revealed China’s People’s Liberation Army has developed capabilities specifically designed to “detect, target, and disrupt” U.S. military operations.

The defense? Metal enclosures and conductive concrete identified as the only viable defense against electromagnetic pulses.

EMI protection moved from best practice to mission requirement.

Understanding the Invisible Threat

Electromagnetic interference occurs when external electromagnetic fields disrupt electronic device functionality. Every electronic system generates electromagnetic waves. When those waves intersect with other systems, interference creates malfunctions ranging from minor glitches to complete failure.

The sources are everywhere.

Wireless devices, lightning strikes, solar magnetic storms, utility power grids, telecommunications infrastructure, and digital signals all generate electromagnetic fields. In military and aerospace applications, high-power radar systems, radio transmitters, and electronic warfare equipment intensify the electromagnetic environment exponentially.

The U.S. Army formally recognizes electromagnetic environmental effects as potential cause factors requiring evaluation during all mishap investigations. Their guidance specifically addresses “modern, complex systems” with electronic components.

Because complexity amplifies vulnerability.

Modern aircraft pack increasing amounts of equipment into compact spaces. Military electronic warfare systems operate at higher frequencies and higher power levels than ever before. As frequency increases, effective shielding becomes more challenging. Higher-frequency signals coupled with increased transmitted power result in greater radiated power. Shield leakage that was negligible at lower frequencies becomes critical at modern operating parameters.

The electromagnetic weapons market reached $879.6 million in 2024. Projections show 21.6% annual growth through 2034, driven by threats from cyber-attacks, electronic warfare, and unmanned systems requiring high-power RF and millimeter-wave weapons. In November 2024, the U.S. military expanded deployment of the Epirus Leonidas High-Power Microwave system. The weapon generates electromagnetic fields that disable electronic components simultaneously across drone swarms.

If we’re building weapons that use EMI, adversaries are too.

Beyond Military Applications

EMI threats extend beyond defense systems into medical environments where failure costs lives. In controlled hospital testing of 41 critical care devices, RFID systems induced 34 EMI incidents. Twenty-two were classified as hazardous, including complete stoppage of ventilators and syringe pumps, external pacemaker malfunctions, and renal replacement device failures.

The median interference distance? Just 9.8 inches. A 1992 incident documented a patient death when ambulance radio interference prevented a monitor-defibrillator from functioning. Two 1987 deaths occurred when monitoring systems failed to sound alarms due to interference.

These aren’t hypothetical scenarios. They’re documented fatalities from inadequate EMI protection. Medical device manufacturers face the same electromagnetic environment as defense contractors. Wireless networks, mobile phones, RFID systems, and other hospital equipment create dense electromagnetic fields. Life-sustaining equipment must function reliably despite constant exposure.

The stakes are absolute.

Best Practices for Custom EMI Shielded Enclosures

Effective EMI protection requires systematic approach across design, materials, manufacturing, and testing.

Material Selection for EMI Shielded Enclosures

Conductive metal materials provide the foundation for effective shielding. Our contract manufacturing services utilize aluminum for excellent shielding effectiveness, providing at least 85 dB of attenuation at frequencies from 30 to 100 MHz.

Most high-frequency shielding problems stem from openings in the shield material rather than the material itself. Gaps, seams, and penetrations create electromagnetic leakage paths that compromise protection regardless of base material quality. Seamless integration eliminates vulnerability.

Manufacturing Process Determines Performance

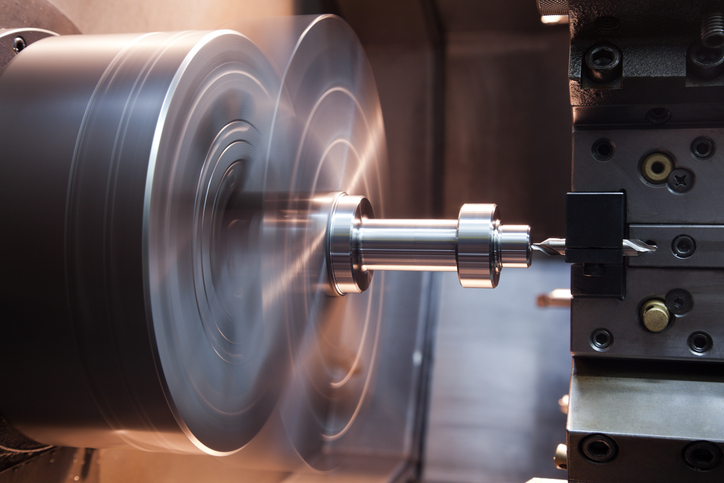

Welding creates heat-affected zones and potential distortion. Mechanical fasteners introduce gaps. Adhesive bonding lacks the conductivity and durability required for mission-critical applications. Aluminum dip brazing eliminates these limitations through complete joint coverage. The process immerses assembled components in molten salt, creating metallurgical bonds without welding distortion.

The filler metal matches or exceeds the conductivity of the base metal. Joint coverage is complete, eliminating the microscopic gaps that compromise shielding effectiveness. The result is sturdy, leak-proof, EMI-shielded joints with improved conductivity throughout the assembly. This precision ensures reliability in military manufacturing applications where failure is not an option.

We’ve specialized in this process for over four decades, and our military machining expertise delivers the seamless protection that ruggedized enclosures require for mission-critical systems.

Custom Design Addresses Specific Requirements

Off-the-shelf enclosures accommodate general applications. Mission-critical systems demand custom solutions engineered for specific electromagnetic environments, thermal requirements, and physical constraints.

Custom enclosures integrate mounting provisions, connector penetrations, and cooling requirements while maintaining complete EMI protection. Our brass milling capabilities complement custom chassis fabrication to ensure protective features remain effective through production and field deployment.

Our collaborative engineering support helps refine designs before production begins. We optimize components for manufacturability, durability, and performance, ensuring that protective features translate from concept to operational hardware.

Testing Validates Real-World Performance

MIL-STD specifications define required shielding effectiveness across frequency ranges. Testing verifies that manufactured enclosures meet these requirements under actual operating conditions.

First Article Inspection validates that newly produced parts meet all engineering and design specifications before full production begins. This verification prevents costly production runs of inadequate protection.

We maintain ITAR compliance, AS9100D certification, and adherence to MIL-SPEC standards throughout our processes. These aren’t administrative checkboxes. They’re systematic validation that our enclosures perform as designed.

The Economics of Prevention

EMI-induced failures in defense and medical applications trigger malpractice lawsuits, regulatory violations, and equipment replacement costs. Compromised data exposes institutions to financial and reputational damage. A failed ventilator or disabled communications system costs more than the equipment itself. Mission failure, legal liability, and loss of life create consequences that dwarf initial procurement savings from standardized solutions.

Proactive investment in custom EMI protection prevents catastrophic costs.

Custom enclosures cost more upfront than off-the-shelf alternatives. But standardized solutions often fail to address specific product requirements. Modifications compromise protection. Field failures necessitate redesign and replacement.

Custom solutions engineered for specific applications deliver optimal protection while accommodating unique design specifications. Single-source manufacturing with integrated dip brazing, CNC machining, and precision metal fabrication streamlines production and ensures consistent quality.

We control each step in the manufacturing process, delivering finished products ready for immediate introduction into production lines. This approach eliminates the time and expense of coordinating multiple suppliers while ensuring single-point accountability.

Dual-Facility Redundancy

Our Fairfield, NJ facility and Ronkonkoma, NY location (New Age Precision Manufacturing) provide operational redundancy and scalability. Defense contractors require assurance of continuity. Dual facilities deliver that certainty.

Our 40,000-square-foot Fairfield plant includes substantial room for growth. As programs scale, our capacity scales with them.

Application-Specific Expertise

Telecommunications systems, military communications equipment, and aerospace avionics each present distinct EMI challenges. Frequency ranges, power levels, environmental conditions, and reliability requirements vary significantly.

We’ve manufactured ruggedized dip-brazed enclosures for defense and aerospace applications since 1979. That experience translates into understanding how different electromagnetic environments affect different systems.

A telecommunications enclosure protecting commercial cellular equipment operates in a different electromagnetic environment than a military communications system deployed in electronic warfare scenarios. Design requirements, testing protocols, and manufacturing tolerances reflect these distinctions.

Our specialization in defense and aerospace applications means we understand MIL-SPEC requirements, ITAR compliance obligations, and the reliability standards that mission-critical systems demand.

Integration with Complex Assemblies

EMI enclosures rarely function in isolation. They integrate with cooling systems, mounting hardware, connector assemblies, and other components. Design must accommodate these integrations without compromising electromagnetic protection.

Connector penetrations create potential leakage paths. Cooling apertures introduce electromagnetic vulnerabilities. Mounting provisions can create ground loops. Effective enclosure design addresses these challenges systematically.

Our in-house capabilities encompass the full manufacturing process. Dip brazing creates the base enclosure. CNC milling machines precision mounting features and connector provisions. Metal fabrication integrates additional components.

This vertical integration ensures that protective features remain effective as designs evolve from concept to finished assembly.

Quality Control Throughout Production

Defense and aerospace applications tolerate zero defects. A single compromised enclosure in a production run creates field failures, mission risks, and potential loss of life.

We maintain rigorous quality control processes throughout manufacturing. Incoming material inspection verifies base metal specifications. In-process inspection confirms dimensional accuracy and joint integrity. Final inspection validates shielding effectiveness and compliance with specifications. Documentation traces every component through production. When defense contractors require material certifications, manufacturing records, and test results, we provide complete documentation for every delivered part.

Traceability isn’t optional in mission-critical applications.

The NAMF Difference

Most metal fabricators offer EMI enclosures as one service among many. We’ve specialized in ruggedized dip-brazed enclosures for defense and aerospace applications for over four decades. That specialization means we understand the electromagnetic environments these systems operate in. We know the failure modes that inadequate shielding creates. We’ve refined manufacturing processes to eliminate the gaps and discontinuities that compromise protection.

Our full in-house capabilities deliver true single-source manufacturing. Dip brazing, CNC machining, and precision metal fabrication occur under one roof with integrated quality control. This eliminates the coordination challenges and quality inconsistencies that multi-supplier approaches create.

Defense contractors and aerospace companies choose us because we deliver precision-engineered solutions to mission-critical projects. Our certifications demonstrate commitment to quality. Our track record proves operational performance.

Moving Forward

Electromagnetic threats continue evolving. Weaponized EMI systems advance. Operating frequencies increase. Power levels rise. The electromagnetic environment becomes more hostile.

Protection requirements evolve accordingly.

Custom EMI shielded enclosures engineered for specific applications provide the robust defense that modern systems require. Dip brazing delivers the seamless joint coverage that eliminates electromagnetic leakage. Vertical integration ensures consistent quality throughout production. We’ve manufactured these solutions since 1979. Our expertise, capabilities, and commitment to quality position us to deliver the EMI protection that defense and aerospace applications demand.

The invisible threat requires tangible solutions. We provide them.

Ready to Protect Your Mission-Critical Systems?

Don’t leave your defense or aerospace equipment vulnerable to electromagnetic threats. Partner with NAMF for precision-engineered EMI shielded enclosures backed by over 40 years of specialized expertise.