- The Problem NADCAP Was Built To Solve

- Why Quality Became the Dominant Factor

- How NADCAP-Approved Suppliers Differ From Standard Quality Certifications

- What the Certification Process Actually Involves

- Merit Levels Reward Consistent Excellence

- The Compound Benefits Across the Ecosystem

- Why Process Auditing Matters More Than Product Inspection

- What NADCAP Certification Signals to the Market

- How We Approach NADCAP at NAMF

- Selecting Suppliers With NADCAP in Mind

- The Standard That Defines Aerospace Manufacturing

- Frequently Asked Questions

Key Takeaways

- NADCAP certification provides process-focused verification that goes beyond product inspection, ensuring aerospace suppliers maintain rigorous controls for mission-critical components where failure has severe consequences.

- The program eliminates redundant supplier audits while delivering measurably lower defect rates, with merit levels (18 and 24 months) rewarding suppliers who demonstrate sustained excellence beyond basic compliance.

- Major aerospace manufacturers, including Boeing, Airbus, Honeywell, and Rolls Royce, require NADCAP approval as a mandatory baseline, making it essential for market access rather than simply a competitive advantage.

When Boeing or Airbus selects a supplier, NADCAP approval isn’t optional. It’s the baseline for entry.

That distinction matters when components operate at 35,000 feet or in defense systems where failure has consequences measured in lives, not just dollars.

We’ve held NADCAP certification at New Age Metal Fabricating since our commitment to aerospace and defense manufacturing began. The process taught us something critical about quality standards: not all certifications carry equal weight.

NADCAP stands apart.

The Problem NADCAP Was Built To Solve

Before 1990, aerospace suppliers faced a frustrating reality. They’d undergo three or four separate audits for the same manufacturing process, each tailored to different OEM expectations.

The redundancy was expensive and time-consuming. Worse, it created inconsistent standards across the industry.

NADCAP emerged to solve this problem by establishing unified standards developed collaboratively by government agencies and industry leaders. Instead of multiple proprietary audits, suppliers could achieve a single certification recognized across the aerospace and defense sectors with NADCAP-approved status.

The program worked because it addressed a genuine pain point while raising the bar for quality assurance.

Why Quality Became the Dominant Factor

Something shifted dramatically in aerospace manufacturing between 2023 and 2024.

Quality prioritization surged from 64% to 94.22% of industry votes. That 30-percentage-point jump reflects heightened scrutiny following high-profile manufacturing issues.

The Boeing 737-MAX 9 incident in January 2024 involved missing fasteners. The Gulfstream G500 and G600 FAA action in June stemmed from incorrectly installed bolts. These weren’t design failures or material defects.

They were manufacturing quality escapes.

When certification importance jumped from 47% to 76.12% in the same period, the message became clear: aerospace buyers want ironclad assurance that suppliers maintain rigorous process controls.

NADCAP provides that assurance in ways generic certifications cannot.

How NADCAP-Approved Suppliers Differ From Standard Quality Certifications

ISO certifications establish baseline quality management systems. They’re valuable but broad, applicable across industries from automotive to medical devices.

NADCAP goes deeper and narrower.

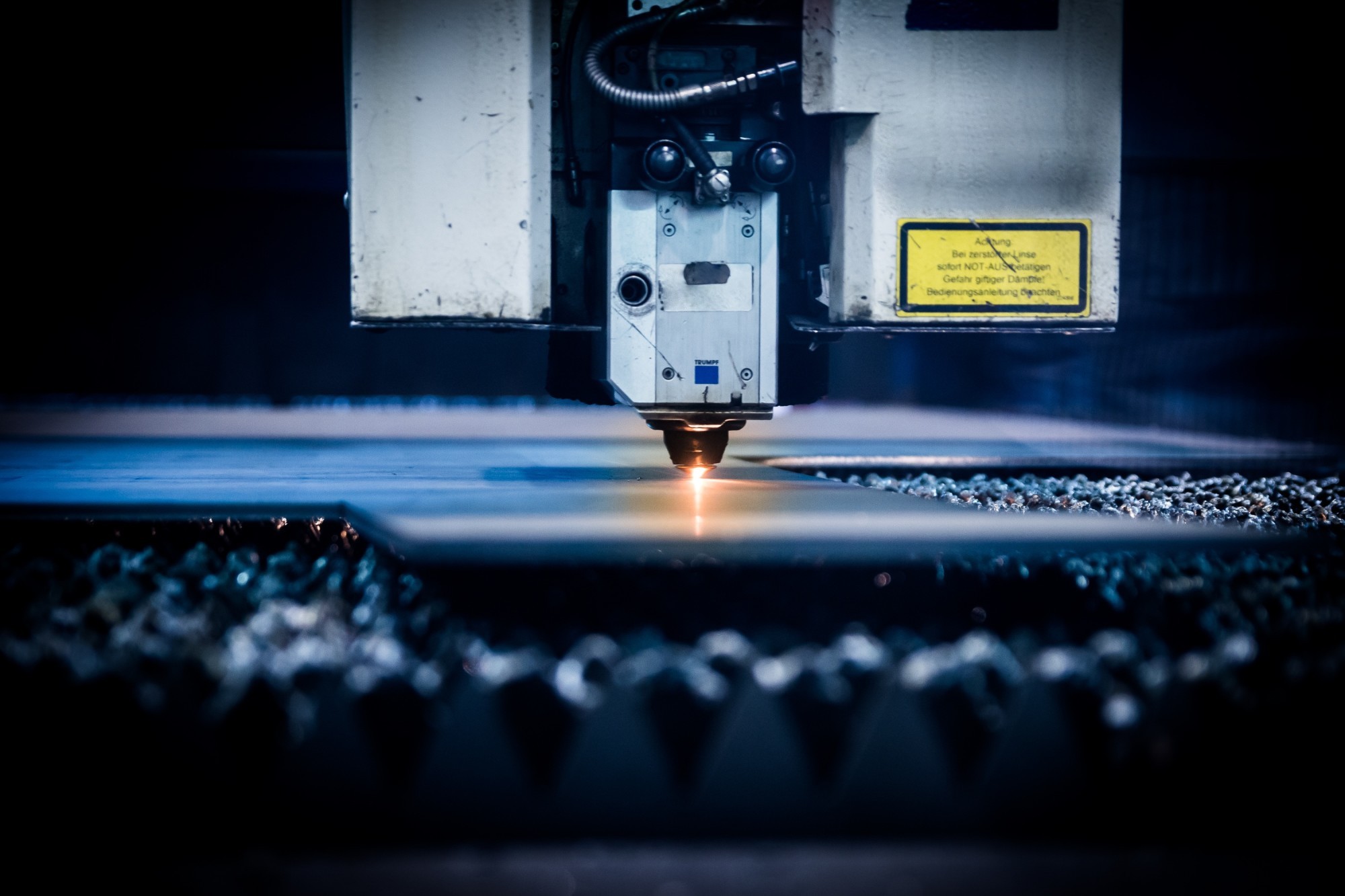

The program focuses exclusively on special processes in aerospace and defense manufacturing: heat treating, welding, nondestructive testing, chemical processing, and 20+ other critical operations, including aluminum dip brazing. These processes can’t be fully verified through inspection of finished parts alone.

You have to evaluate the process itself.

That’s the fundamental difference. NADCAP auditors don’t just examine your end products. They scrutinize every step of your manufacturing process, from how work orders are received to final delivery protocols.

The auditor base averages over 30 years of aerospace industry experience with deep technical expertise in their specific commodity. These aren’t generalist quality assessors reading from a checklist.

They’re subject matter experts who understand the physics, chemistry, and engineering principles underlying each process, from precision fabrication to specialized joining techniques.

What the Certification Process Actually Involves

NADCAP certification begins with selecting the specific processes you want accredited. At NAMF, we maintain certifications in multiple areas relevant to our dip brazing, metal fabrication, and CNC milling capabilities for custom CNC parts.

The audit evaluates five critical dimensions:

- Process controls and documentation. Auditors verify that you’ve established written procedures for every manufacturing step and that personnel follow them consistently.

- Equipment calibration and maintenance. All measurement instruments and production equipment must demonstrate regular calibration against traceable standards.

- Personnel qualifications and training. Operators must possess documented competencies for the processes they perform, with ongoing training records maintained.

- Material traceability and control. Raw materials, work-in-progress, and finished components require complete chain-of-custody documentation for contract manufacturing services.

- Nonconformance handling and corrective action. Your system for identifying, documenting, and resolving quality issues undergoes thorough examination.

Initial accreditation lasts 12 months. Then the real test begins.

Merit Levels Reward Consistent Excellence

NADCAP offers two merit levels for suppliers who demonstrate sustained performance: 18-month merit and 24-month merit.

These extended audit cycles aren’t automatic. They’re earned through consistent compliance, minimal findings in previous audits, and demonstrated commitment to continuous improvement.

Merit status signals something important to aerospace buyers: this supplier doesn’t just meet standards during audit preparation. They maintain exacting processes as standard operating procedure.

We’ve found that pursuing merit levels drives internal improvements beyond what certification alone requires. The goal becomes embedding quality into organizational culture, not performing for periodic audits.

That cultural shift delivers compound benefits.

The Compound Benefits Across the Ecosystem

NADCAP certification creates value that cascades through the aerospace supply chain.

For buyers, it eliminates redundant supplier audits while providing confidence in component quality. Defense contractors and aerospace OEMs can focus resources on design and integration rather than verifying each supplier’s basic process controls.

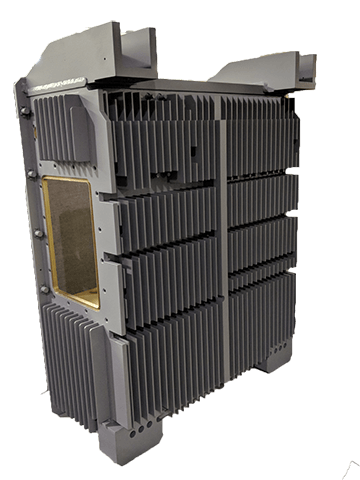

The quality assurance extends beyond paperwork. NADCAP-certified suppliers demonstrate measurably lower defect rates and reduced field failures across applications from EMI-shielded enclosures to structural components. When specifications are met through turning and milling operations, production lines run smoother and warranty costs decrease.

For suppliers, certification opens doors that remain closed to non-certified competitors. Major aerospace manufacturers, including Boeing, Airbus, Honeywell, and Rolls-Royce, make NADCAP a mandatory requirement for suppliers of special process components.

That’s not market preference. It’s market access.

The standardized processes also improve internal operations. Reduced rework and scrap rates directly impact profitability. Clear documentation and process controls make scaling production more predictable.

For the industry, widespread NADCAP adoption raises the floor for manufacturing quality. Component failures decrease. Safety improves. The entire aerospace ecosystem benefits from standardized expectations and verified capabilities.

Why Process Auditing Matters More Than Product Inspection

Here’s what catches many suppliers off guard: NADCAP audits your processes, not your products.

You can’t prepare by producing a batch of perfect parts for inspection. Auditors want to see how you produce parts consistently, day after day, across different operators and production runs.

This process-focused approach addresses a fundamental limitation of product inspection. Some manufacturing defects only reveal themselves under operational stress or over time. A heat-treated component might pass dimensional inspection but fail prematurely if the heat treatment process wasn’t properly controlled.

NADCAP verification ensures that the processes producing your components maintain the parameters necessary for long-term reliability.

That’s why aerospace buyers value NADCAP certification so highly. It provides assurance that extends beyond what any receiving inspection can deliver.

What NADCAP Certification Signals to the Market

Achieving NADCAP certification communicates several messages simultaneously.

- First, you’ve invested in proper equipment, training, and process controls. The certification isn’t inexpensive to obtain or maintain, which naturally filters out suppliers unwilling to make that commitment.

- Second, you understand aerospace and defense requirements at a fundamental level. NADCAP’s industry-managed governance means the standards reflect real operational needs, not generic quality concepts.

- Third, you’re willing to submit to ongoing external verification. The periodic reaudits demonstrate continued commitment rather than one-time achievement.

These signals matter in industries where supplier relationships often span decades and component failures can ground fleets or compromise defense systems.

NADCAP certification has become a baseline qualification for participating in aerospace manufacturing at the tier where precision and reliability aren’t negotiable.

How We Approach NADCAP at NAMF

Our NADCAP certifications complement our other quality credentials, including NAVSEA accreditation. Each certification addresses different aspects of our quality management system.

The NADCAP processes align naturally with our specialization in ruggedized dip-brazed enclosures and precision-machined components for defense and aerospace applications. These products demand the exact process controls that NADCAP verification ensures.

We maintain certifications across our dual facilities in Fairfield, NJ, and Ronkonkoma, NY. That geographic redundancy provides clients with operational continuity while demonstrating our commitment to consistent standards across locations.

The ongoing audit cycles drive continuous improvement in our manufacturing processes. Each reaccreditation becomes an opportunity to refine procedures, update equipment, and enhance personnel training.

That’s the real value of NADCAP certification. It’s not a static achievement but a framework for sustained excellence.

Selecting Suppliers With NADCAP in Mind

When evaluating aerospace suppliers, NADCAP certification should be a primary consideration, not an afterthought.

Start by verifying which specific processes hold NADCAP accreditation. A supplier might be certified for heat treating but not for welding or nondestructive testing. Ensure their certifications match your component requirements.

Check their accreditation history. Multiple reaccreditations demonstrate sustained commitment. Merit-level status indicates exceptional performance over time.

Ask about their quality management systems beyond NADCAP. The best aerospace partners combine NADCAP approval with complementary certifications and robust internal quality controls.

Review their customer base. Suppliers working with major aerospace primes have proven their ability to meet exacting standards under real-world production pressures.

Finally, evaluate their engineering support capabilities. NADCAP certifies processes, but the best suppliers also offer collaborative design assistance to optimize components for manufacturability and performance.

The Standard That Defines Aerospace Manufacturing

NADCAP certification has evolved from a solution to audit redundancy into the defining standard for aerospace manufacturing quality.

The program’s industry-managed governance ensures standards remain relevant as technologies and requirements evolve. The rigorous auditor qualifications maintain consistency across evaluations. The merit system rewards sustained excellence rather than one-time compliance.

For aerospace buyers, NADCAP provides assurance that suppliers maintain the process controls necessary for mission-critical components. For suppliers, it delivers market access and operational improvements that justify the certification investment.

The 30-year track record demonstrates that standardized, process-focused quality verification works. As aerospace manufacturing faces increasing scrutiny and complexity, NADCAP’s role as the industry’s quality gatekeeper will only grow more important.

Quality isn’t negotiable when components operate in environments where failure has severe consequences. NADCAP certification provides the standardized verification that aerospace and defense applications demand.

That’s why major OEMs make it mandatory. That’s why we maintain it across our facilities. And that’s why it separates suppliers who understand aerospace requirements from those who don’t.

Partner With a NADCAP-Certified Leader

Ready to work with a supplier that meets the aerospace industry’s highest standards? NAMF’s NADCAP certifications and 40+ years of experience deliver the quality and reliability your mission-critical projects demand.