- Understanding CNC Turning and Milling Fundamentals

- When CNC Turning Takes the Lead

- Where CNC Milling Dominates Manufacturing

- The Selection Framework That Eliminates Guesswork

- Advanced Technology Integration

- Best Practices From Four Decades of Experience

- Making the Strategic Choice

- Frequently Asked Questions

Key Takeaways

- CNC turning excels at cylindrical components with superior surface finishes and concentricity control.

- Milling dominates complex geometries requiring multiple features and multi-axis machining capabilities.

- Process selection depends on geometry analysis, volume requirements, and tolerance specifications.

One wrong cut destroys months of work. In defense and aerospace manufacturing, that reality hits harder than anywhere else. We’ve seen projects worth millions hinge on a single machining decision. The choice between turning and milling can make or break your timeline, budget, and reputation.

Both processes remove material to create precision components. Both generate chips, use cutting fluids, and rely on computer-controlled accuracy. But their similarities end there.

The differences determine everything.

Understanding CNC Turning and Milling Fundamentals

Turning and milling represent the backbone of modern precision manufacturing. These subtractive processes systematically remove material from stock to create exact specifications. Computer Numerical Control technology programs both through CAD software, eliminating human error and ensuring repeatability.

The global CNC machine market reflects this critical importance. Valued at $95.29 billion in 2024, it’s projected to reach $195.59 billion by 2032. That’s a 9.9% compound annual growth rate, driven by one factor: demand for precision.

Both processes work with identical materials. Aluminum, steel, brass, copper, titanium, and thermoplastics all respond to either method. Both generate heat, requiring cutting fluid management. Both produce waste chips that must be cleared efficiently.

The similarities create a foundation. The differences create strategy.

When CNC Turning Takes the Lead

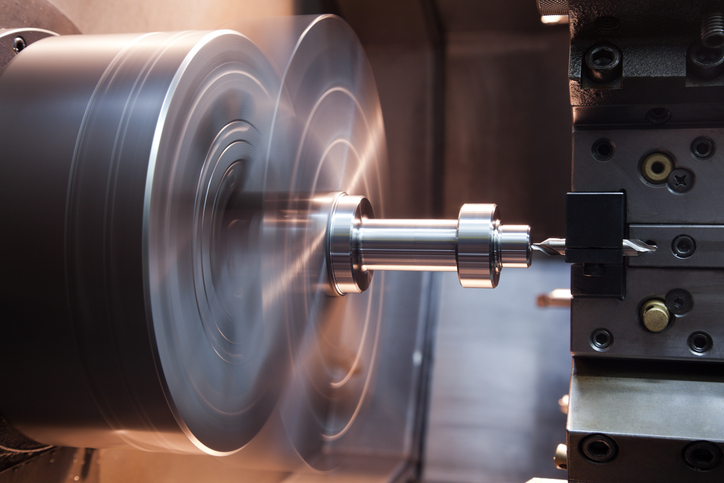

CNC turning excels at cylindrical components. The workpiece rotates while a stationary cutting tool shapes the material. This rotation creates natural advantages for specific geometries.

Shafts, bolts, and pulleys emerge from turning operations with superior surface finishes. The continuous cutting action eliminates the tool marks common in other processes. For components requiring tight concentricity, turning delivers unmatched precision.

We see turning dominate in aerospace applications requiring cylindrical precision. Landing gear pins, hydraulic actuators, and engine components benefit from turning’s rotational advantages. The process creates smooth, consistent surfaces critical for high-stress applications.

Turning also offers speed advantages for cylindrical work. Setup time remains minimal when producing multiple similar components. The single-point cutting tool creates efficient material removal without complex tool changes.

But turning has limitations that turning and milling comparisons must address.

Where CNC Milling Dominates Manufacturing

CNC milling moves cutting tools around stationary workpieces. This fundamental difference opens possibilities turning cannot match. Complex geometries, intricate features, and multi-sided machining become accessible.

Custom CNC milling creates the ruggedized enclosures we specialize in at NAMF. These defense and aerospace components require precise pockets, slots, and mounting features. Multiple cutting tools can machine different features without repositioning the workpiece.

The versatility extends to material utilization. Brass milling and aluminum milling service operations can work with irregular stock shapes, reducing waste and material costs. Complex contours and three-dimensional features emerge from single setups.

High-precision engineering represents the fastest-growing market segment. Defense, medical, and aerospace sectors drive this demand for complex, precise components that only milling can achieve.

Advanced milling centers offer five-axis capabilities. Understanding 3-axis vs. 5-axis milling becomes critical for complex geometries. Horizontal milling configurations provide additional advantages for specific applications. These machines create geometries impossible with traditional three-axis setups.

The Selection Framework That Eliminates Guesswork

Choosing between turning and milling requires systematic evaluation. We’ve developed a framework that eliminates guesswork and reduces costly mistakes.

Geometry Analysis

Start with part geometry. Cylindrical components with rotational symmetry favor turning. Complex shapes with multiple features require milling capabilities. Consider the primary features. If concentricity and surface finish dominate requirements, turning provides advantages. If pockets, slots, or mounting features are critical, milling becomes necessary.

Volume Considerations

Production volume affects process selection. High-volume cylindrical parts benefit from turning’s efficiency. Lower volumes with complex features may justify milling setup costs. Material removal rates vary between processes. Turning typically removes material faster for cylindrical work. Milling offers flexibility but may require longer cycle times.

Tolerance Requirements

Both processes achieve tight tolerances, but through different mechanisms. Turning excels at maintaining cylindrical tolerances and surface finishes. Milling provides precise dimensional control across multiple axes. In aerospace and defense applications, even minor deviations can cause failures.

Advanced Technology Integration

Modern CNC technology continues advancing both processes. Multi-axis capabilities expand possibilities for complex geometries. Automation reduces labor costs and improves consistency.

Turn mill centers combine both processes in single machines. These hybrid systems reduce setup time and improve accuracy by eliminating workpiece transfers. Complex components requiring both cylindrical and prismatic features benefit from this integration.

Adaptive control systems optimize cutting parameters in real-time. These systems adjust speeds and feeds based on cutting conditions. The result: consistent quality and extended tool life.

Predictive maintenance prevents unexpected downtime. Sensors monitor machine condition and predict maintenance needs. This capability becomes critical for high-volume production schedules.

Best Practices From Four Decades of Experience

Since 1979, we’ve refined our approach to both processes. These practices separate successful projects from costly mistakes.

Material preparation affects both processes. Consistent stock dimensions reduce setup time and improve accuracy. Pre-machined blanks can eliminate roughing operations. Material condition matters. Stress-relieved stock machines more predictably.

Cutting parameter optimization determines success or failure. Conservative parameters ensure quality but reduce efficiency. Aggressive settings risk tool breakage and scrap parts. We start with manufacturer recommendations, then adjust based on specific conditions.

Tool selection impacts quality, efficiency, and cost. Premium tools justify their cost through longer life and better finishes. Tool condition monitoring prevents sudden failures. Regular inspection catches wear before it impacts part quality.

Making the Strategic Choice

The choice between turning and milling depends on specific requirements. Cylindrical components with rotational symmetry favor turning. Complex shapes with multiple features require milling capabilities.

Consider the complete manufacturing picture. Setup costs, cycle times, and quality requirements all influence the decision. Volume projections affect process economics.

At NAMF, we evaluate each project individually. Our four decades of experience guide process selection for optimal results. We consider geometry, tolerances, materials, and production requirements.

The goal remains constant: deliver precision components that meet specifications on time and within budget. Both processes serve essential roles in modern manufacturing. Understanding their capabilities and limitations enables better decisions.

Ready to Choose the Right Manufacturing Process?

Don’t let the wrong machining choice derail your project timeline and budget. Our experienced team evaluates your specific requirements and recommends the optimal process for your precision components.