- The Technical Foundation of Rapid Prototype Machining

- Five Competitive Advantages That Matter

- Implementation Methodology That Works

- Overcoming Implementation Challenges

- Future Trajectory and Competitive Implications

- The NAMF Advantage in Rapid Prototype Machining

- Ready to Accelerate Your Defense Manufacturing Timeline?

- Frequently Asked Questions

Key Takeaways

- Rapid prototype machining reduces development cycles from months to days while maintaining defense-grade precision standards.

- Digital control eliminates human error variables and tooling costs that traditional machining requires.

- Companies adopting rapid prototyping now gain competitive advantages in the growing $6.3 billion market by 2032.

The rapid prototyping market is exploding from $2.5 billion to $6.3 billion by 2032. That growth represents more than numbers. It signals a fundamental shift in how precision manufacturing operates. Defense and aerospace contractors are abandoning traditional machining timelines that stretch across months. They’re embracing rapid prototype machining that compresses development cycles into days while maintaining the exacting standards their applications demand.

We’ve observed this transformation firsthand at New Age Metal Fabricating. Since 1979, we’ve evolved from conventional metal fabrication to cutting-edge capabilities that serve mission-critical defense and aerospace applications.

The difference between traditional and rapid prototype machining methods extends far beyond speed.

The Technical Foundation of Rapid Prototype Machining

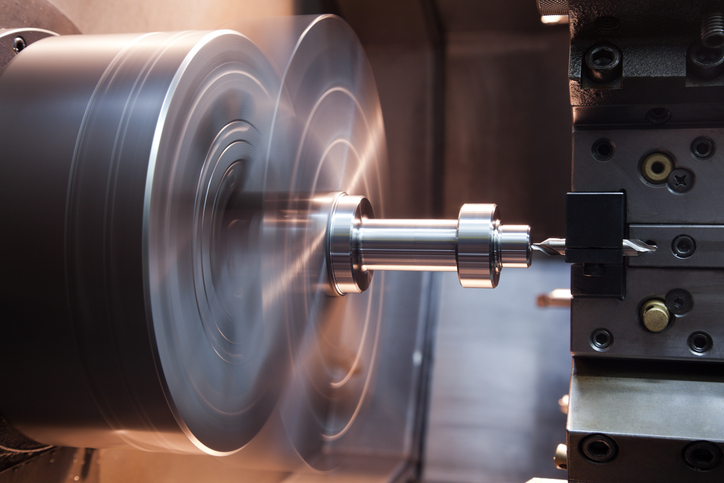

Rapid prototype machining leverages computer-aided design (CAD) integration with advanced CNC systems to produce functional prototypes directly from digital models. The process eliminates multiple intermediary steps that traditional machining requires.

Modern CNC systems achieve tolerances as tight as ±0.0005 inches (0.01 mm). That precision level approaches the thickness of human hair.

The technical advantage becomes clear when you consider defense applications. Ruggedized enclosures for military electronics cannot tolerate dimensional variations that compromise environmental sealing or electromagnetic shielding.

Traditional machining approaches these requirements through iterative tooling adjustments and multiple test runs. Rapid prototype machining achieves the same precision through direct digital control, eliminating human error variables and reducing setup time.

Our dip brazing capabilities exemplify this precision advantage. Aluminum components requiring hermetic sealing depend on exact dimensional control to achieve proper joint formation. It ensures these critical dimensions remain consistent across prototype iterations.

Five Competitive Advantages That Matter

Compressed Development Timelines

Traditional machining requires tooling design, fabrication, and testing before the first prototype emerges. This process typically consumes 8–12 weeks for complex defense components.

Rapid prototype machining eliminates tooling requirements entirely. Digital files translate directly into machined parts within days. The time savings accelerate entire product development cycles.

Enhanced Precision Through Digital Control

CNC systems execute programmed instructions with mathematical precision. Human variables that affect traditional machining accuracy disappear when digital systems control every cutting operation.

This precision advantage becomes critical for aerospace applications, where component failures can have catastrophic consequences. Every dimension must meet specification without exception.

Superior Design Flexibility

Design modifications require only software updates rather than physical tooling changes. Engineers can test multiple design iterations rapidly, optimizing performance before committing to production tooling.

We regularly work with defense contractors who need to evaluate different enclosure configurations for electromagnetic compatibility. Rapid prototype machining allows them to test multiple designs within the same timeframe traditional methods would require for a single prototype.

Reduced Tooling Investment

Traditional machining often requires custom fixtures, jigs, and cutting tools for complex geometries. These tooling costs can exceed $50,000 for sophisticated defense components.

Rapid prototype machining eliminates most tooling requirements through programmable machine setups. The cost savings become substantial when multiple design iterations are necessary.

Accelerated Innovation Cycles

Faster prototyping enables more design experimentation within fixed development budgets. Engineering teams can explore innovative solutions that would be cost-prohibitive using traditional methods.

This acceleration factor drives competitive advantage in defense contracting, where innovation typically determines contract awards.

Implementation Methodology That Works

Successful rapid prototype machining implementation follows a structured approach that we’ve refined through decades of defense and aerospace work.

Digital File Optimization

CAD files must be optimized for rapid prototype machining constraints. Material properties, cutting tool limitations, and machine capabilities all influence design feasibility.

Our engineering team collaborates with clients during this optimization phase, ensuring designs achieve intended performance while remaining manufacturable through rapid methods.

Comprehensive Cost Analysis

Rapid prototype machining costs differ significantly from traditional machining economics. Setup costs decrease while material utilization efficiency increases.

We provide detailed cost analysis that compares rapid prototype machining expenses against traditional alternatives, including time-to-market considerations that affect overall project economics.

Streamlined Production Execution

Production scheduling becomes more flexible when tooling constraints disappear. Multiple projects can share machine capacity without extensive changeover procedures.

Our dual-facility capability in Fairfield, NJ and Ronkonkoma, NY provides redundancy and capacity scaling that defense contractors require for critical programs. This infrastructure supports both rapid prototype machining and high volume CNC machining when projects scale to production.

Rigorous Quality Validation

Defense and aerospace applications demand comprehensive testing protocols. First Article Inspection (FAI) procedures verify that prototypes meet all engineering specifications before production approval.

Our NADCAP and AS9100D certifications ensure quality processes meet the stringent requirements these industries demand.

Overcoming Implementation Challenges

Rapid prototype machining adoption faces predictable obstacles that successful implementation must address.

Material Constraints

Not all materials suit rapid prototype machining methods equally. Specialized alloys used in defense applications may require process modifications or alternative approaches.

Our materials expertise helps clients navigate these constraints, identifying suitable alternatives or hybrid approaches that achieve required performance characteristics. Our aluminum milling service capabilities ensure optimal results with lightweight aerospace materials.

Technical Knowledge Gaps

Engineering teams familiar with traditional machining may lack experience. This knowledge gap can slow adoption and reduce effectiveness.

We provide technical consultation that bridges this gap, sharing our experience to accelerate client learning curves and optimize results.

Quality Assurance Concerns

Defense contractors cannot compromise quality standards for speed advantages. Rapid prototype machining processes must demonstrate equivalent or superior quality control.

Our quality management systems address these concerns through documented procedures and statistical process control that meets defense industry requirements. Combined with our precision welding services, we ensure every prototype meets exacting specifications.

Future Trajectory and Competitive Implications

Rapid prototype machining technology continues evolving at an accelerating pace. 3D printing adoption reached 74.09% in aerospace prototyping during 2024, indicating widespread industry acceptance.

Artificial intelligence integration will further optimize tool paths and predict maintenance requirements before critical failures occur. These advancements will make rapid prototype machining even more attractive for defense applications.

Sustainable materials development addresses environmental concerns while maintaining performance standards. This evolution supports defense industry sustainability initiatives without compromising mission requirements.

Companies that master rapid prototype machining capabilities now will maintain competitive advantages as these technologies mature. Those that delay adoption risk falling behind innovation curves in precision-dependent markets.

The market growth projections reflect this competitive reality. Organizations investing in capabilities position themselves for sustained success in evolving defense and aerospace markets.

The NAMF Advantage in Rapid Prototype Machining

Our integrated capabilities distinguish us from other metal fabrication companies who offer only partial solutions. Dip brazing, precision machining, and metal fabrication under one roof eliminates coordination complexity that slows many projects.

Decades of defense and aerospace experience inform our approach to rapid prototype machining implementation. We understand the unique requirements these industries impose and design our processes accordingly.

Our dual-facility operations provide redundancy and capacity scaling that large defense programs require. This infrastructure investment demonstrates our commitment to serving these critical markets.

ITAR compliance and security protocols ensure sensitive defense projects receive appropriate handling throughout the prototyping process.

When defense and aerospace contractors need capabilities that meet their exacting standards, they choose partners with proven performance in these demanding applications. We’ve built our reputation on delivering precision-engineered solutions that support mission-critical requirements.

Ready to Accelerate Your Defense Manufacturing Timeline?

Don’t let traditional manufacturing timelines slow your critical defense projects. Our proven capabilities have accelerated development cycles for aerospace and defense contractors for over four decades.