- The Defense Budget Is Speaking Loudly

- Precision Metal Cutting Through Fiber-Optic Technology

- How Precision Metal Cutting Tolerances Impact Mission Success

- Integration Eliminates Hidden Costs

- Certifications Reflect Capability, Not Marketing

- Dip Brazing Remains a Specialized Advantage

- The Supply Chain Is a Strategic Concern

- Technology Integration Continues Accelerating

- What This Means for Defense Contractors

- The Precision Standard Keeps Rising

- Frequently Asked Questions

Key Takeaways

- Fiber-optic laser technology delivers cutting speeds 4-5 times faster than traditional methods while achieving tolerances as tight as 0.003 inches for defense-grade components.

- Integrated manufacturing capabilities eliminate supply chain fragmentation, reducing coordination overhead and timeline vulnerabilities for mission-critical aerospace projects.

- Defense sector investment has surged 340% over the past decade, intensifying demand for manufacturers with ITAR-compliant facilities and specialized processes like dip brazing.

Precision in metal cutting isn’t measured in millimeters anymore. It’s measured in microns.

In defense and aerospace manufacturing, deviations smaller than a human hair can compromise performance and safety. The stakes are absolute. The tolerances are unforgiving.

And the technology required to meet these demands has evolved faster than most people realize. The precision metal cutting techniques required for today’s defense applications would have been impossible just a decade ago.

We’re seeing a fundamental shift in how precision metal components are manufactured for mission-critical applications. The aerospace & defense segment now holds 30.3% of the sheet metal fabrication services market in 2024, reflecting the sector’s growing demand for advanced manufacturing capabilities.

This growth isn’t gradual. It’s accelerating.

The Defense Budget Is Speaking Loudly

DoD budget requests for procurement and R&D related to missiles and munitions have increased by 340% over the last decade, reaching $30.6 billion in fiscal 2024 from $9 billion in fiscal 2015.

That level of investment creates immediate pressure on the supply chain.

Defense contractors need manufacturing partners who can deliver precision-engineered components at scale, on time, and to exacting specifications. They need suppliers who understand that AS9100 certification isn’t a suggestion. ITAR compliance isn’t optional. First Article Inspection isn’t bureaucracy.

These are the baseline requirements for participating in defense manufacturing.

But meeting baseline requirements doesn’t create competitive advantage. What separates capable manufacturers from exceptional ones is technological sophistication and operational integration.

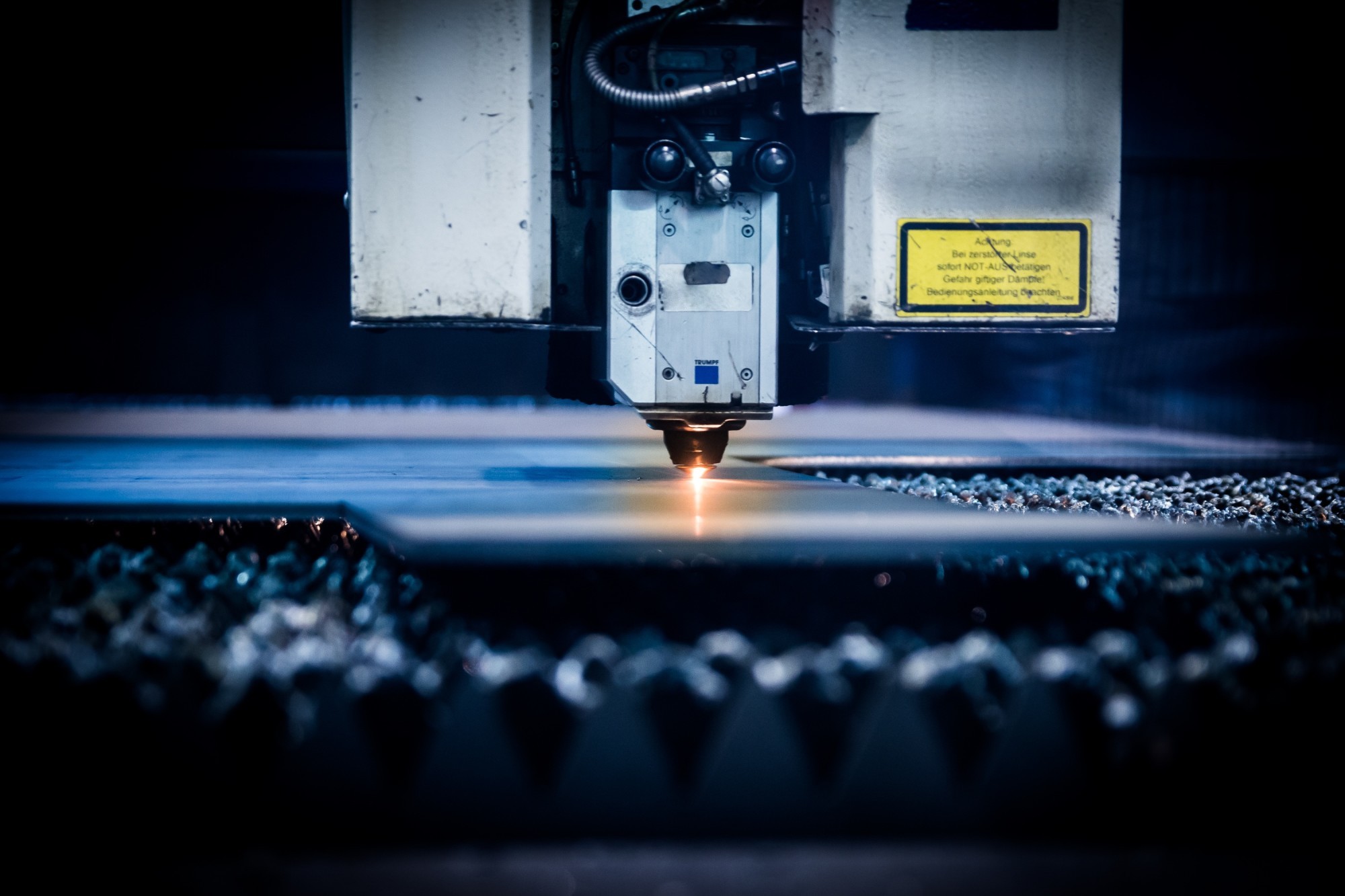

Precision Metal Cutting Through Fiber-Optic Technology

Traditional metal cutting methods struggle with the precision tolerances required in modern aerospace and defense applications. CO2 lasers and mechanical cutting have limitations in speed, accuracy, and material compatibility. Among metal fabrication companies serving defense contractors, those with advanced laser systems hold distinct competitive advantages.

Fiber lasers achieve speeds 4-5 times faster than traditional YAG lasers. Their photoelectric conversion efficiency is approximately 10 times higher, with conversion rates of 30-50% compared to CO2 lasers’ 10-15%.

That efficiency translates directly into operational advantages.

At New Age Metal Fabricating, we operate a TruLaser 2030 4 kW Fiber-Optic laser that processes materials four times faster than conventional CO2 laser systems while using approximately one-third of the energy. The spot size is up to 100 times smaller compared to CO2 lasers, with a wavelength of only 1064 nanometers.

This matters because reflective metals like aluminum, copper, and brass that are difficult or impossible to process with CO2 lasers become manageable with fiber-optic technology.

For defense contractors manufacturing ruggedized enclosures or precision aerospace components, material flexibility isn’t a luxury. It’s a requirement.

How Precision Metal Cutting Tolerances Impact Mission Success

A Boeing 747-8 contains 6 million parts. Each one must meet specific tolerances. Each one must perform reliably under extreme conditions.

Manufacturing tolerances for aerospace components now demand accuracy where deviations smaller than a human hair impact performance. Leading manufacturers achieve tolerances ranging from .0001″ to .000005″ for aerospace and defense applications.

Turbine blades. Landing gear. Structural elements. Avionics housings.

These components don’t tolerate approximation.

We’ve been manufacturing precision metal components since 1979, and we’ve watched tolerance requirements tighten consistently over four decades. What was considered precise in 1985 wouldn’t qualify for defense work today. What’s considered precise today will likely be insufficient in 2030.

The trajectory is clear. Precision requirements will continue escalating as systems become more sophisticated and performance demands increase.

Integration Eliminates Hidden Costs

Most defense contractors work with multiple suppliers for different fabrication processes. One vendor for laser cutting. Another for CNC machining. A third for dip brazing. A fourth for finishing and coating. This is where military fabrication projects often encounter delays and quality inconsistencies.

This fragmentation creates coordination overhead, quality inconsistency, and timeline vulnerability.

When a single component requires four different suppliers, you’re managing four different quality systems, four different delivery schedules, and four different points of potential failure. If one supplier misses a specification or deadline, your entire production timeline shifts.

We operate as a single-source supplier with full in-house capabilities across dip brazing, CNC machining, and precision metal fabrication. Our facilities in Fairfield, NJ, and Ronkonkoma, NY, under New Age Precision Manufacturing, provide operational redundancy and expanded capacity.

This integration means defense contractors get complete, turnkey solutions with a single point of contact. We control each step in the manufacturing process and deliver finished products ready for immediate introduction into production lines.

The time savings are significant. The quality consistency is measurable. The risk reduction is substantial.

Certifications Reflect Capability, Not Marketing

AS9100 rev D certification includes 105 additional requirements beyond ISO 9001 specific to the aerospace sector. These requirements cover production control, design and development, product safety, counterfeit parts prevention, and risk management.

We maintain AS9100, NADCAP, and NAVSEA certifications because our defense and aerospace clients require them. But certifications alone don’t manufacture components. They validate that your quality management systems, processes, and controls meet industry standards.

What actually manufactures components is technological capability combined with operational expertise.

Our CNC machining centers, including advanced 5-axis milling capabilities, produce complex geometries with tight tolerances. Our Amada punch presses handle high-volume production with consistency. Our welding meets AWS standards. Our chemical conversion coating meets military specifications. Our military machining operations combine precision equipment with specialized expertise in defense-grade components.

These capabilities, backed by certifications, create the foundation for reliable defense manufacturing partnerships.

Dip Brazing Remains a Specialized Advantage

Aluminum dip brazing is a specialized process that many metal fabricators don’t offer. Our brazing services utilize aluminum dip brazing techniques perfected over six decades of continuous operation. It involves immersing metal assemblies in molten salt to create strong, hermetically sealed joints with excellent thermal conductivity.

For ruggedized enclosures used in military applications, dip brazing provides structural integrity that welding or mechanical fastening can’t match. The process creates joints that withstand extreme temperatures, vibration, and environmental stress.

New Age Precision Manufacturing has over 60 years of experience in aluminum dip brazing with NADCAP and NAVSEA approvals. This specialization gives defense contractors access to a capability that’s increasingly difficult to source domestically.

When you need ruggedized enclosures for avionics, communications equipment, or weapons systems, dip brazing isn’t optional. It’s the manufacturing method that meets MIL-SPEC requirements. For chassis fabrication in military vehicles and aerospace systems, dip brazing delivers the structural integrity and thermal performance that mission-critical applications demand.

The Supply Chain Is a Strategic Concern

Defense contractors are increasingly focused on supply chain resilience. Dependence on overseas manufacturing creates vulnerabilities. Reliance on multiple domestic suppliers creates coordination complexity.

Both scenarios introduce risk that defense programs can’t tolerate.

Working with a single-source supplier who maintains full in-house capabilities and operates ITAR-compliant facilities reduces these vulnerabilities. You’re not managing a supply chain. You’re managing a partnership with a manufacturer who controls the entire production process.

This matters more as defense budgets increase and program timelines compress. The commercial aerospace segment alone could require an additional 123,000 technicians in the next two decades, demonstrating massive growth and demand for skilled manufacturing capabilities.

Competition for manufacturing capacity will intensify. Defense contractors who establish relationships with capable, integrated manufacturers now will have strategic advantages over those who continue managing fragmented supply chains.

Technology Integration Continues Accelerating

Machine learning algorithms are enhancing laser cutting efficiency and precision, reducing errors and improving real-time adjustments. AI integration into machining processes is revolutionizing how machines are programmed and optimized.

We’re investing in these technologies because our clients’ requirements demand continuous improvement. Automated laser cutting systems with minimal human intervention reduce labor costs while improving consistency. CNC control enables repeatable cuts with minimal variation, ideal for high-volume production.

The narrow kerf and precise nesting algorithms reduce material waste. We’re also exploring sustainable metals and recycling processes that align with DOD environmental initiatives without compromising performance standards. Smooth, burr-free edges often eliminate the need for secondary finishing. Non-contact processing reduces tool wear and risk of deformation or contamination.

These advantages compound over time. Small efficiency gains in cutting speed, material utilization, and quality consistency add up to significant cost reductions and capability improvements across thousands of components.

What This Means for Defense Contractors

If you’re sourcing precision metal components for defense or aerospace applications, you’re evaluating more than just price per unit. You’re evaluating manufacturing capability, quality systems, delivery reliability, and supply chain risk.

The manufacturers who can deliver on all these dimensions simultaneously are the ones who will support your programs successfully over multi-year timelines.

We’ve built our business around being that kind of manufacturing partner. Full in-house capabilities. Specialized processes like dip brazing. Advanced technologies like fiber-optic laser cutting. Dual facilities for redundancy. Certifications that validate our quality systems.

These aren’t marketing claims. They’re operational realities that determine whether components meet specifications and arrive on schedule.

The Precision Standard Keeps Rising

Metal fabrication for defense and aerospace isn’t getting easier. Tolerances are tightening. Materials are becoming more sophisticated. Performance requirements are escalating. Supply chain scrutiny is intensifying.

Manufacturers who can’t keep pace with these demands will lose access to defense work. Those who invest in technology, maintain rigorous quality systems, and provide integrated capabilities will become increasingly valuable partners.

We’ve been adapting to rising standards since 1979. Our facilities, technologies, and processes reflect four decades of continuous investment in precision manufacturing capabilities.

When defense contractors need ruggedized enclosures, precision-machined components, or dip-brazed assemblies, they need a manufacturing partner who understands that precision is measured in microns, not millimeters.

That understanding shapes everything we do.

From our TruLaser 2030 fiber-optic laser to our 5-axis CNC machining centers to our specialized dip brazing capabilities, we’ve built an operation designed specifically for the demands of defense and aerospace manufacturing.

If your programs require precision-engineered metal components manufactured to MIL-SPEC standards, delivered on time, and backed by AS9100 and NADCAP certifications, we should talk.

The defense manufacturing landscape is changing rapidly. The contractors who adapt their supply chains now will have advantages over those who wait.

Precision metal cutting is redefining what’s possible in defense manufacturing. The question is whether your supply chain is ready for what comes next.

Partner With Precision Manufacturing Experts

Ready to work with a manufacturing partner who delivers precision-engineered components for defense and aerospace applications? Our integrated capabilities, ITAR-compliant facilities, and specialized processes ensure your programs stay on schedule and on spec.