Most precision fabrication shops compete on price and speed, but the smart ones compete on specialized capabilities most shops don’t even know exist.

After four decades in precision metal fabrication, we’ve seen countless shops struggle with the same fundamental challenge. They have the basic equipment, skilled operators, and solid processes. But they’re missing the specialized tools that separate competent fabrication from truly exceptional work.

The difference often comes down to three pieces of equipment that most fabricators either overlook or consider too specialized for their operations. These tools represent the hidden competitive advantages that enable shops to tackle complex projects, maintain tighter tolerances, and deliver results that command premium pricing.

Here are the three secret weapons that transform good precision fabrication shops into industry leaders.

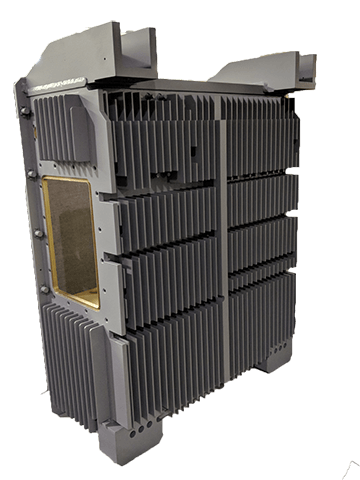

Horizontal Boring Mills and Vertical Gantry Mills

Precision boring separates amateur operations from professional precision fabricating shops.

Most fabricators rely on standard milling equipment for their machining operations. This approach works fine for general applications, but it falls short when projects demand the kind of precision that defense and aerospace clients require.

Horizontal boring mills achieve accuracy levels that standard equipment simply cannot match. These machines maintain micrometer-level precision during long, deep boring operations, ensuring diameter accuracy, coaxiality, and concentricity within tolerances that approach the theoretical limits of precision fabrication.

The robust construction of these machines provides the stability necessary for extended machining operations. While standard mills might introduce vibration or deflection during complex cuts, horizontal boring mills maintain their precision throughout the entire operation. This capability becomes critical when fabricating components for mission-critical applications. A slight deviation in bore concentricity might be acceptable for commercial applications, but it represents complete failure in aerospace or defense contexts.

Vertical gantry mills complement horizontal boring capabilities by providing the workspace and rigidity needed for large, complex assemblies. These machines handle workpieces that would overwhelm standard equipment while maintaining the precision necessary for tight-tolerance work.

The combination of horizontal boring precision and vertical gantry capacity creates machining capabilities that most precision fabrication shops cannot replicate. This equipment represents a significant investment, but it opens access to projects that command premium pricing and long-term client relationships.

Portable Coordinate Measuring Machines

Quality control determines whether precision fabrication succeeds or fails.

Traditional quality control approaches work well for standard fabrication, but they create bottlenecks when dealing with complex geometries and tight tolerances. Fixed CMM systems require controlled environments and significant setup time, making them impractical for many precision fabrication workflows.

Portable CMMs eliminate these constraints while maintaining measurement accuracy of 0.025 mm. These systems operate effectively on the shop floor, without requiring controlled environments or extensive setup procedures. The flexibility of portable measurement systems transforms quality control from a bottleneck into a competitive advantage. Operators can verify dimensions and geometries at any point in the fabrication process, catching potential issues before they become costly problems.

This capability proves especially valuable for complex assemblies where multiple components must align precisely. Rather than waiting until final assembly to discover fit issues, fabricators can verify each component’s accuracy as it comes off the machine.

The speed and accessibility of portable CMMs also enable statistical process control approaches that would be impractical with fixed measurement systems. Fabricators can collect dimensional data throughout production runs, identifying trends and making adjustments before parts move outside acceptable tolerances.

For defense and aerospace applications, this level of quality control represents the difference between acceptable and exceptional precision fabrication. Clients in these industries expect comprehensive documentation and verification, requirements that portable CMMs fulfill efficiently.

Modular Welding Tables

Assembly accuracy determines whether precision components function as intended.

Understanding welding vs. fabrication processes becomes crucial when discussing assembly accuracy. Standard welding tables provide a flat surface for joining components, but they offer limited flexibility for complex assemblies. Fabricators often spend significant time creating custom fixtures and jigs for each project, adding cost and complexity to every job.

Modular welding tables eliminate this inefficiency by providing a reconfigurable platform that adapts to different assembly requirements. The precision-machined holes and surfaces ensure perfect alignment and stability for any configuration. The time savings alone justify the investment in modular systems. Projects that previously required hours of setup and fixturing can be configured in minutes, allowing fabricators to focus on the actual assembly work rather than preparation.

More importantly, modular tables improve assembly accuracy by providing consistent reference points and alignment features. The precision-machined surfaces ensure that components maintain their intended relationships throughout the welding process.

This accuracy becomes critical when assembling components that must integrate with other systems. A slight misalignment during assembly can cascade into major fit issues when the completed assembly reaches its final application.

The versatility of modular systems also enables fabricators to handle a wider range of projects without investing in specialized fixtures for each application. This flexibility represents a significant competitive advantage when bidding on diverse custom sheet metal fabrication projects.

The Competitive Reality

These three tools represent more than equipment upgrades. They create capabilities that most precision fabrication shops cannot replicate.

Horizontal boring mills and vertical gantry mills provide machining precision that opens access to high-value projects. Portable CMMs enable quality control approaches that ensure consistent results while reducing inspection bottlenecks. Modular welding tables streamline assembly operations while improving accuracy.

The combination of these capabilities creates a precision fabrication operation that can tackle projects other shops cannot handle. This differentiation translates into premium pricing, long-term client relationships, and sustainable competitive advantages.

Most fabricators focus on conventional equipment and standard processes. They compete primarily on price and delivery time, accepting thin margins and commodity-level positioning.

Shops that invest in specialized capabilities can command premium pricing because they deliver results that standard operations cannot achieve. The initial investment in advanced equipment pays dividends through access to higher-value projects and more profitable client relationships.

The defense and aerospace industries particularly value fabricators who can demonstrate advanced capabilities. These clients prioritize precision, reliability, and comprehensive quality control over low-cost alternatives. Building relationships with these clients requires demonstrating capabilities that go beyond standard fabrication. The three tools outlined here provide the foundation for that demonstration.

Implementation Strategy

Acquiring advanced precision fabrication capabilities requires strategic planning and significant investment.

The key is understanding how these tools integrate into existing operations and complement current capabilities. Horizontal boring mills and vertical gantry mills expand machining capacity into precision applications. Portable CMMs streamline quality control while improving documentation. Modular welding tables increase assembly efficiency and accuracy.

Each tool addresses specific bottlenecks that limit fabrication performance. Rather than general-purpose equipment upgrades, these represent targeted investments in capabilities that create competitive differentiation.

The return on investment comes through access to projects that require these specialized capabilities. Defense and aerospace clients pay premium prices for fabricators who can demonstrate the precision and quality control necessary for mission-critical applications.

Building these capabilities also requires developing operator expertise and establishing processes that maximize the equipment’s potential. The technology provides the foundation, but successful implementation depends on skilled operators and systematic approaches.

Training and process development represent ongoing investments that compound the initial equipment costs. However, these investments create sustainable fabrication advantages that justify the total cost of capability development.

The fabrication industry continues evolving toward higher precision and more complex applications. Shops that invest in advanced capabilities position themselves to capitalize on these trends, while those that rely on standard equipment face increasing pressure on margins and market position.

These three secret weapons provide the foundation for building a precision fabrication operation that competes on capability rather than price. The investment is significant, but the competitive advantages justify the commitment for shops serious about long-term success in precision fabrication.

Key Takeaways

- Horizontal boring mills and vertical gantry mills provide machining precision that opens access to high-value defense and aerospace projects.

- Portable CMMs enable real-time quality control that catches issues before they become costly problems.

- Modular welding tables streamline assembly operations while improving accuracy for complex fabrication projects.

Ready to Transform Your Fabrication Capabilities?

Don’t let your competition gain the upper hand with superior precision fabrication capabilities. These three secret weapons represent the difference between competing on price and commanding premium rates for exceptional work.