- The Real Cost of Environmental Extremes

- Material Science Meets Manufacturing Reality

- The Integration Challenge: Where Systems Meet Reality

- Emerging Trends Reshaping the Industry

- The Manufacturing Capability Gap

- The Single-Source Solution Advantage

- Looking Forward: The Next Decade of Military Manufacturing

- Making the Right Ruggedized Enclosure Manufacturing Partner Decision

- The Bottom Line on Ruggedized Enclosures

- Frequently Asked Questions

Key Takeaways

- The rugged electronics market is projected to reach $28.50 billion by 2030, driven by increasing demand for equipment that survives extreme military and aerospace environments.

- Advanced manufacturing processes like aluminum dip brazing deliver superior environmental sealing, EMI shielding, and thermal management compared to conventional joining methods.

- Selecting a manufacturing partner requires evaluating proven defense experience, in-house capabilities, active certifications (AS9100, NADCAP, ITAR), and engineering support.

The rugged electronics market is experiencing explosive growth. From $14.2 billion in 2022 to a projected $28.50 billion by 2030, this sector is expanding at a 9.1% annual rate. North America leads the charge. The U.S. market alone is expected to reach $7.2 billion by 2025.

These numbers tell a story. Something fundamental is happening in defense and aerospace manufacturing.

We’re not just seeing incremental improvements. We’re witnessing a complete transformation in how military and aerospace systems are designed, built, and deployed. The equipment operating in these environments faces challenges that would destroy standard commercial-grade enclosures within hours.

At 36,000 feet, atmospheric pressure drops to one-fifth of sea level. Oxygen partial pressure falls from 21 kPa to just 4.7 kPa. Ground-based military vehicles navigate dust storms, salt fog, extreme temperature swings, and vibration levels that would shake apart conventional assemblies.

Failure isn’t an inconvenience. It’s catastrophic.

The Real Cost of Environmental Extremes

Military and aerospace equipment doesn’t operate in controlled environments. These systems face simultaneous assaults from multiple environmental factors. Each factor is capable of causing failure on its own.

Temperature extremes range from arctic cold to desert heat. Electronic components must function reliably in sub-zero conditions or scorching temperatures. The challenge isn’t just surviving these temperatures. It’s maintaining precision performance throughout the range.

Vibration and shock present equally serious threats. Military vehicles traverse rough terrain at high speeds. Aircraft experience turbulence, hard landings, and constant vibration. A single loose connection or cracked solder joint can disable critical systems at the worst possible moment.

The financial implications are staggering. A single component failure during a mission can result in equipment losses worth millions. More importantly, it can endanger lives and compromise mission objectives that took months or years to plan.

This reality drives demand for ruggedized enclosures that go far beyond basic protection. These solutions represent the foundation of defense machining excellence.

Understanding MIL-STD-810: The Benchmark for Survival

MIL-STD-810 defines what it means for equipment to survive in military environments. This United States Military Standard specifies environmental tests. These tests determine whether equipment can withstand the conditions it will experience throughout its service life.

The standard addresses a comprehensive range of environmental conditions:

- Low-pressure testing for altitude performance

- High and low-temperature exposure plus thermal shock

- Rain and humidity resistance

- Fungus growth prevention

- Salt fog corrosion testing

- Sand and dust exposure

- Explosive atmosphere compatibility

- Leakage prevention

- Acceleration and shock resistance

- Gunfire vibration tolerance

- Random vibration endurance

Meeting these standards requires more than just using tough materials. It demands precision engineering, advanced manufacturing processes, and rigorous quality control at every step.

Material Science Meets Manufacturing Reality

The materials used in ruggedized enclosures directly determine their performance capabilities. Magnesium and aluminum alloys offer the optimal combination of lightweight strength. This combination is essential for structural support in military-grade applications.

Weight matters significantly in aerospace and defense applications. Every pound added to an aircraft reduces fuel efficiency and payload capacity. Ground vehicles must balance protection with mobility. The term SWaP—Size, Weight, and Power—has become central to military equipment design.

Small form factor chassis are specifically engineered for military vehicles and platforms where space and weight are at a premium.

These rugged conduction-cooled enclosures must withstand harsh conditions. They face dust, salt fog, temperature extremes, and high levels of shock and vibration. Yet they must maintain minimal size and weight profiles.

Aluminum emerges as the preferred material for many applications. It provides excellent strength-to-weight ratios while offering superior corrosion resistance and thermal management properties. When combined with advanced joining techniques, aluminum enclosures deliver performance that exceeds welded or mechanically fastened alternatives.

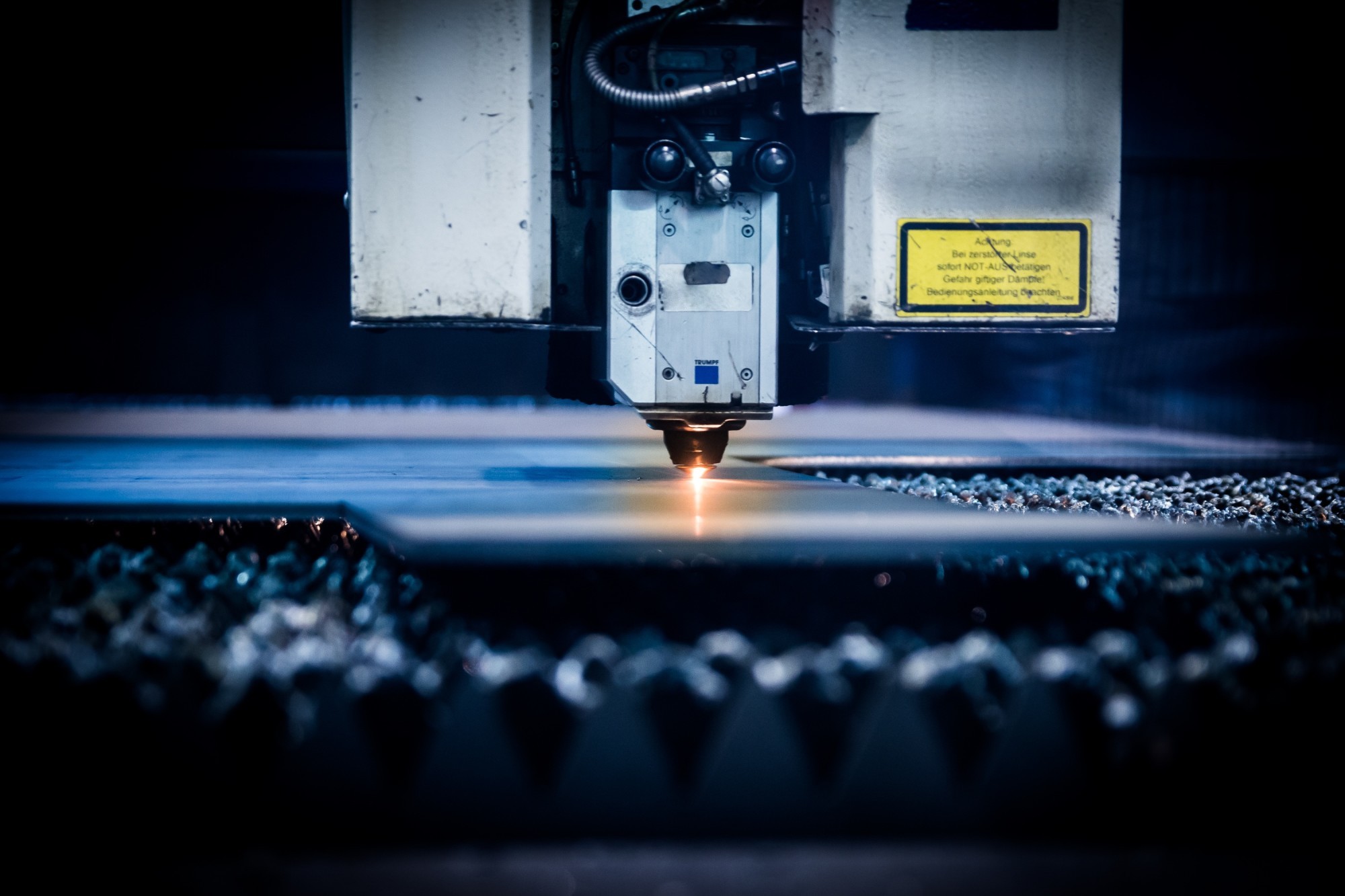

The Dip Brazing Advantage

Dip brazing represents a specialized manufacturing process. It creates advantages specifically aligned with ruggedized enclosure requirements. This method joins metal parts by immersing them in molten salt. The result is continuous, uniform joints throughout the assembly.

The benefits are substantial and measurable:

- Superior environmental sealing. The continuous joints created through dip brazing eliminate gaps and weak points. Spot welding and mechanical fastening leave these vulnerabilities. This creates enclosures that maintain their integrity under pressure differentials, moisture exposure, and contamination threats.

- Enhanced EMI shielding. Electromagnetic interference can disrupt sensitive electronics or compromise communications. The uniform metal-to-metal bonds created by dip brazing provide consistent EMI protection across the entire enclosure surface.

- Precise dimensional control. The dip brazing process heats metals uniformly. This reduces the risk of distortion compared to welding. This precision matters when enclosures must fit within tight tolerances or interface with other components.

- Improved thermal management. The continuous joints create efficient heat transfer paths throughout the structure. As processor speeds increase in military computers, thermal management becomes increasingly critical. Heat that isn’t properly dissipated leads to component failure.

- Production efficiency. All joints in a component can be brazed simultaneously. This produces components quickly and evenly. The efficiency translates to faster delivery times without sacrificing quality.

We’ve seen these advantages play out across numerous defense and aerospace applications. The ruggedized housings for sensitive electronics require all these characteristics simultaneously. They need precise dimensions, EMI shielding, reliable environmental sealing, and superior thermal management.

The Integration Challenge: Where Systems Meet Reality

Ruggedized enclosures don’t exist in isolation. They must integrate seamlessly with the electronic systems they protect. At the same time, they must meet increasingly demanding performance requirements.

Complex, highly sensitive aerospace and defense electronics face challenges that compound each other. Electromagnetic interference degrades signal integrity. Heat buildup reduces component reliability. Vibration and shock can cause intermittent connections or complete failures.

The enclosure must address all these challenges simultaneously. It cannot add excessive size, weight, or complexity.

This is where design for manufacturability becomes essential.

Engineers must consider how components will be manufactured, assembled, and tested from the earliest design stages. A design that looks perfect on paper may prove impossible to manufacture consistently. It may create assembly challenges that increase costs and lead times.

Collaborative engineering support helps optimize components before production begins. We work with clients to refine designs for manufacturability, durability, and performance. This collaboration identifies potential issues early. Changes are still relatively simple and inexpensive to implement at this stage.

The ITAR Compliance Imperative

International Traffic in Arms Regulations (ITAR) govern the export and import of defense-related materials and information. Manufacturers serving defense contractors must comply with these regulations. Compliance is necessary to handle sensitive projects.

ITAR compliance isn’t just a regulatory checkbox. It represents a commitment to security and proper handling of controlled information and materials. This compliance enables manufacturers to work on classified projects. It allows them to handle technical data that requires protection.

For defense contractors selecting suppliers, ITAR compliance is often a baseline requirement. Without it, a manufacturer simply cannot participate in many defense projects. Technical capabilities don’t matter without compliance.

Emerging Trends Reshaping the Industry

The ruggedized enclosure market isn’t static. Several trends are driving significant changes in how these components are designed and manufactured.

AI and machine learning integration. Rugged embedded AI supercomputers are transforming real-time processing for military autonomous systems and surveillance. These systems require enclosures that can dissipate heat from high-performance processors. They must maintain electromagnetic compatibility and survive harsh environmental conditions.

The computational demands of AI systems create thermal management challenges. These challenges exceed previous generations of military electronics. Enclosures must evolve to handle increased heat loads without adding significant weight or volume.

Autonomous and unmanned systems proliferation. The military’s increasing reliance on autonomous vehicles creates demand for advanced solutions. Both ground-based and aerial vehicles need custom CNC parts and ruggedized enclosures. These components must operate without human intervention for extended periods. Systems must maintain reliability across mission durations that may span days or weeks in hostile environments.

Rising military budgets and modernization programs. The United States is experiencing rising military budgets and associated vehicle upgrades. This drives demand for ruggedized display systems and related components. Defense, aerospace, and manufacturing sectors require resilient and reliable solutions. These solutions must remain functional under demanding conditions.

Advanced certification requirements. AS9100 certification and NADCAP accreditation are becoming standard expectations rather than differentiators. These quality management systems demonstrate a manufacturer’s commitment to aerospace and defense industry standards.

First Article Inspection (FAI) processes verify that newly produced parts meet all engineering and design specifications. This happens before full production begins. This verification step catches issues early. It prevents costly production runs of non-conforming parts.

The Sustainability Factor

Environmental considerations are increasingly influencing manufacturing decisions. This applies even in defense and aerospace applications. Aluminum offers advantages here as well. It’s highly recyclable without loss of properties. Recycling aluminum requires only 5% of the energy needed to produce primary aluminum.

Manufacturers are integrating environmentally friendly processes and materials into their operations. They maintain the performance standards required for military and aerospace applications. This isn’t about compromising capability for sustainability. It’s about achieving both.

The Manufacturing Capability Gap

Not all metal fabrication shops can produce ruggedized enclosures that meet military and aerospace requirements. The gap between standard commercial fabrication and defense-grade manufacturing is substantial.

Specialized equipment requirements. Advanced CNC machining, including 5-axis capabilities, enables the production of complex geometries with tight tolerances. Dip brazing facilities require specialized equipment and expertise. Most fabricators don’t possess these capabilities.

Quality control intensity. Defense and aerospace applications demand rigorous quality control processes at every manufacturing stage. Inspection equipment, documented procedures, and trained personnel all contribute to consistent quality.

Certification and compliance overhead. Maintaining AS9100, NADCAP, and ITAR compliance requires ongoing investment. Systems, training, and audits all demand resources. These certifications represent significant barriers to entry for manufacturers attempting to serve defense and aerospace markets.

Engineering expertise. Understanding the unique requirements of ruggedized applications requires deep industry knowledge. Engineers must comprehend not just how to manufacture components. They must understand how those components will perform in extreme operational environments.

We’ve invested over four decades building these capabilities. Our facilities in Fairfield, NJ, and Ronkonkoma, NY, provide redundancy and scalability. We maintain consistent quality standards across locations.

The Single-Source Solution Advantage

Defense and aerospace contractors face pressure to reduce costs, accelerate delivery schedules, and maintain quality standards. Managing multiple suppliers for different manufacturing processes adds complexity. It extends lead times and creates coordination challenges.

A single-source supplier offering integrated capabilities streamlines production. Dip brazing, CNC machining, and precision metal fabrication under one roof ensures consistent quality.

Reduced coordination overhead. Working with one supplier instead of three or four eliminates communication complexity. It removes potential for miscommunication between vendors. Changes can be implemented faster when all processes happen under one roof.

Faster problem resolution. When issues arise, having all manufacturing processes in-house enables rapid troubleshooting and correction. There’s no finger-pointing between suppliers about where a problem originated.

Consistent quality standards. A single quality management system governs all processes. This ensures uniform standards from raw material receipt through final inspection.

Accelerated delivery times. Eliminating transportation time between multiple suppliers reduces overall lead times. The scheduling coordination required to move parts through different facilities disappears.

We provide complete, turnkey solutions that control each step in the manufacturing process. This approach delivers finished products ready for immediate introduction into production lines. It saves clients time and expense while ensuring a single point of contact for their projects.

Looking Forward: The Next Decade of Military Manufacturing

The projected growth to $28.50 billion by 2030 reflects more than market expansion. It represents the increasing sophistication and criticality of military and aerospace electronics.

Several factors will drive continued growth and evolution:

- Increased electronic content in military systems. Modern military equipment incorporates more electronics than ever before. Each new system requires ruggedized protection. This multiplies demand for high-quality enclosures.

- Longer service lives. Military equipment often remains in service for decades. Ruggedized enclosures must maintain their protective capabilities throughout extended service lives. This requires materials and manufacturing processes that deliver long-term durability.

- Greater performance demands. As electronics become more powerful, they generate more heat. They also become more sensitive to environmental factors. Enclosures must evolve to protect increasingly capable and delicate systems.

- Expanded operational environments. Military systems are deployed in more diverse environments than ever before. From arctic conditions to tropical humidity to desert heat. Enclosures must perform reliably across this entire range.

The manufacturers who will succeed in this evolving market combine specialized expertise, advanced capabilities, and rigorous quality systems. They maintain flexibility to adapt to changing requirements in military manufacturing.

We’ve positioned ourselves to meet these challenges through continuous investment in equipment, training, and process improvements. Our focus on innovation, quality, and customer satisfaction aligns with the demands of this critical market.

Making the Right Ruggedized Enclosure Manufacturing Partner Decision

Selecting a supplier for ruggedized enclosures involves more than comparing quotes. The decision impacts product quality, delivery schedules, and ultimately mission success.

Key evaluation criteria should include:

- Proven track record in defense and aerospace. Experience matters in these demanding applications. A manufacturer with decades of successful projects demonstrates their capability. They meet stringent requirements consistently.

- Comprehensive in-house capabilities. Integrated manufacturing processes reduce complexity and improve quality control. Verify that potential suppliers can handle all required processes. They shouldn’t outsource critical steps.

- Current certifications and compliance. Confirm that manufacturers maintain active AS9100, NADCAP, and ITAR certifications. These aren’t one-time achievements. They require ongoing compliance and regular audits.

- Engineering support capabilities. The best suppliers offer more than manufacturing. They provide engineering expertise to optimize designs for manufacturability and performance.

- Quality control systems. Review the inspection equipment, procedures, and documentation systems that ensure consistent quality. Ask about First Article Inspection processes and ongoing quality verification.

- Capacity and scalability. Evaluate whether a manufacturer can handle your current needs and scale production if requirements increase. Facility size, equipment capability, and workforce all factor into this assessment with military machining projects.

We welcome these discussions. Our 40,000-square-foot manufacturing facility in Fairfield, NJ, provides ample room for growth. Our Ronkonkoma location adds redundancy and additional capacity.

The Bottom Line on Ruggedized Enclosures

The rapid growth of the ruggedized electronics market reflects a fundamental reality. Military and aerospace systems are becoming more sophisticated, more electronic, and more dependent on reliable protection from harsh environments.

The enclosures protecting these systems must deliver on multiple fronts simultaneously. Environmental sealing, EMI shielding, thermal management, dimensional precision, and durability. All while minimizing size, weight, and power consumption.

Advanced manufacturing processes like aluminum dip brazing provide measurable advantages over conventional joining methods. These advantages translate directly to improved system reliability and mission success.

The manufacturers succeeding in this market combine specialized expertise, comprehensive capabilities, rigorous quality systems, and flexibility. They adapt to evolving requirements. They don’t just fabricate metal. They engineer solutions to complex protection challenges.

As military and aerospace electronics continue advancing, demand for ruggedized enclosures that can keep pace will only intensify. The $28 billion market projection isn’t just a number. It’s a measure of how critical reliable equipment protection has become to national defense and aerospace operations.

Partner with NAMF for Your Ruggedized Enclosure Needs

Ready to discuss your project requirements? Our integrated manufacturing capabilities, specialized expertise, and commitment to quality can support your next mission-critical project.