Key Takeaways

- Custom chassis fabrication has evolved from manual processes to sophisticated digital manufacturing with advanced materials and precision engineering.

- Specialized joining techniques like dip brazing create superior thermal and structural performance in critical defense and aerospace applications.

- Quality standards and compliance requirements are non-negotiable aspects of custom chassis fabrication for mission-critical systems.

The world of custom chassis fabrication has undergone remarkable transformation over the past four decades. What once relied heavily on manual processes and basic tooling has evolved into a sophisticated discipline leveraging advanced technologies, materials science, and precision engineering. This evolution mirrors the journey at New Age Metal Fabricating (NAMF), where they’ve witnessed and participated in the industry’s growth since their founding in 1979.

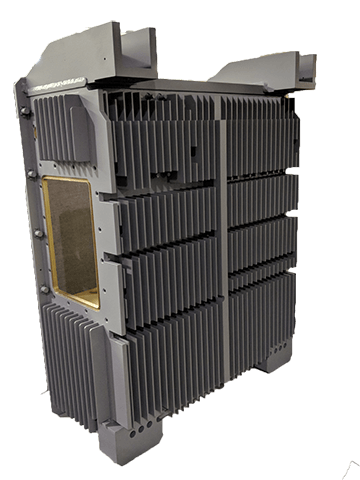

Custom chassis fabrication represents the backbone of critical systems in defense and aerospace applications. These specialized frameworks provide structural integrity, thermal management, and protection for sensitive electronics and components operating in the most demanding environments. Understanding the processes, technologies, and applications driving this field offers valuable insight into broader manufacturing trends reshaping the industry.

The Foundation of Modern Chassis Fabrication

Custom chassis fabrication begins with precision design. Today’s engineers leverage sophisticated CAD software to create detailed 3D models that account for structural requirements, thermal considerations, and integration with other systems. This digital foundation enables simulation testing under various conditions before any physical material is processed.

The material selection process has become increasingly sophisticated. While aluminum remains the predominant choice for aerospace and defense applications due to its excellent strength-to-weight ratio and thermal conductivity, there’s a growing adoption of specialized alloys engineered for specific performance characteristics. Each material selection represents a careful balance between mechanical properties, weight considerations, thermal management, and cost efficiency.

Core Processes in Custom Chassis Fabrication

Modern chassis fabrication involves several core processes that have been refined over decades:

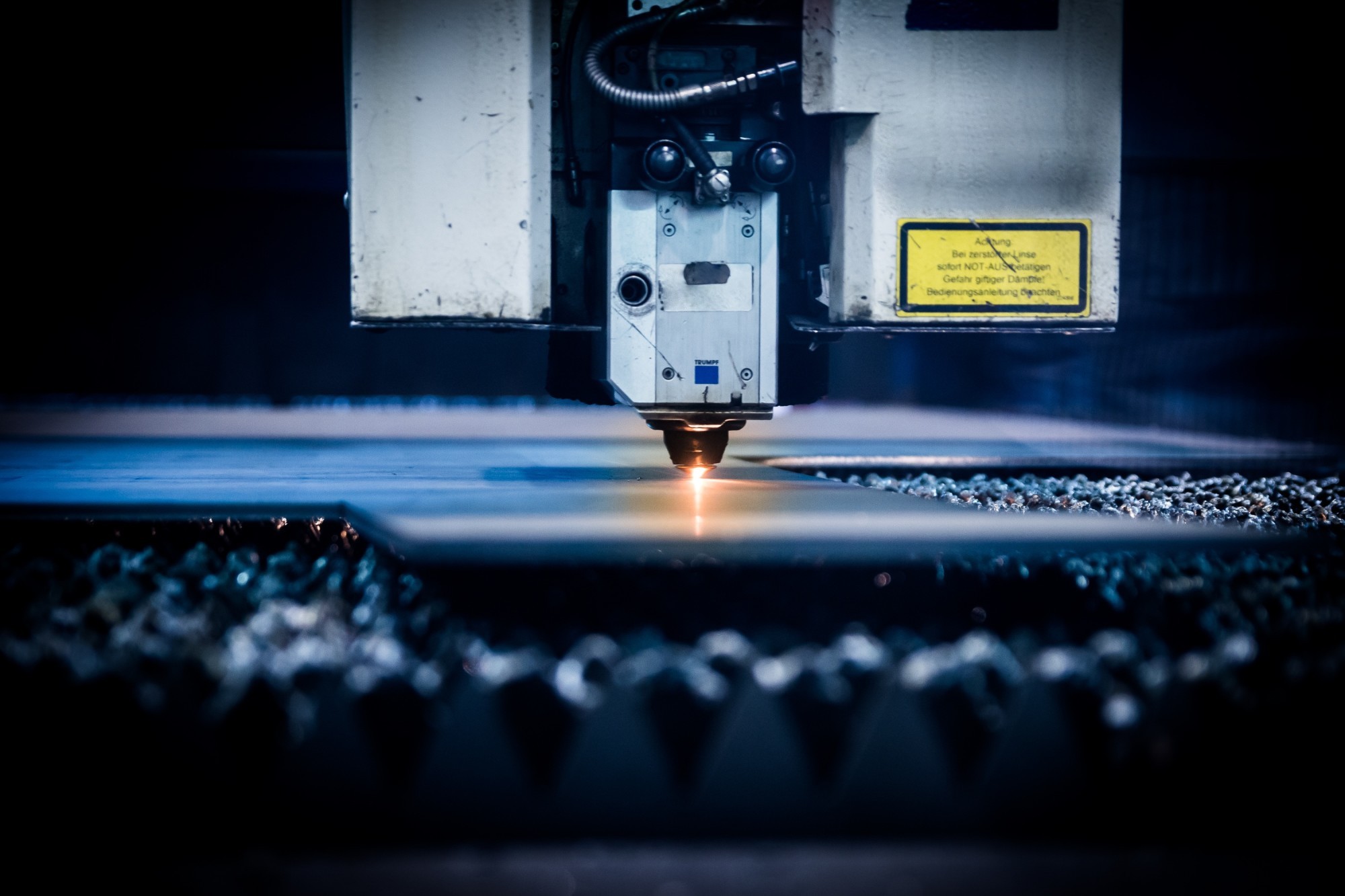

- Precision Cutting: CNC laser and water jet cutting technologies have revolutionized the initial fabrication stage. These computer-controlled systems achieve tolerances measured in thousandths of an inch, creating components with exceptional accuracy and repeatability.

- Forming Operations: Advanced press brake technology enables precise bending of metal components. Computer-controlled systems ensure consistent results across production runs, maintaining critical dimensions and angles essential for components that must mate perfectly during assembly.

- Joining Techniques: Specialized processes like dip brazing have become essential for creating robust, thermally conductive chassis assemblies. This technique creates joints with exceptional strength and thermal transfer properties by immersing components in molten salt baths, outperforming traditional fastening methods in demanding applications.

- Surface Finishing: Chemical conversion coating, anodizing, and specialized painting processes protect chassis components from corrosion while enhancing their functional properties—particularly critical for components deployed in harsh environments.

Technological Advancements Reshaping the Industry

The custom chassis fabrication landscape continues to evolve through significant technological advancements. Several key technologies are driving this transformation:

Advanced CNC Machining

Multi-axis CNC machining centers have dramatically expanded manufacturing capabilities. Five-axis machining allows for complex geometries to be created in single setups, reducing production time and improving accuracy. These systems enable the creation of intricate cooling channels, precision mounting features, and complex structural elements that optimize both form and function.

The production of machined aluminum parts has become increasingly sophisticated, with tolerances that were once considered impossible now becoming standard in high-performance applications. This precision is essential for chassis components that must integrate seamlessly with other systems.

Additive Manufacturing Integration

While not replacing traditional fabrication methods, additive manufacturing has found its place in the chassis fabrication workflow. 3D printing technologies enable rapid prototyping of complex designs and the production of specialized components that would be difficult or impossible to create through conventional methods.

Advanced Metrology

Coordinate measuring machines (CMMs) and 3D scanning technologies have transformed quality control processes. These systems capture millions of data points to verify dimensional accuracy against design specifications. Real-time monitoring during production allows for immediate adjustments, reducing scrap rates and ensuring consistent quality.

Digital Thread Implementation

The concept of maintaining a digital thread throughout the manufacturing process has gained significant traction. This approach creates a continuous data flow from design through production, quality control, and even field service. For chassis fabrication, this means improved traceability, more efficient process adjustments, and better communication between different manufacturing stages.

Critical Applications in Defense and Aerospace

Custom chassis fabrication plays a vital role in numerous defense and aerospace applications where reliability is non-negotiable:

Ruggedized Electronics Enclosures

Military and aerospace systems require protective housings that shield sensitive electronics from extreme temperatures, vibration, electromagnetic interference, and environmental factors. Enclosure fabrication techniques have evolved to create solutions that provide this protection while facilitating thermal management through integrated cooling features.

Avionics Systems

Modern aircraft rely on sophisticated electronic systems for navigation, communication, and control. The chassis housing these components must meet stringent requirements for weight, thermal management, and structural integrity while complying with relevant industry standards.

Radar and Communication Systems

Advanced radar and communication equipment depends on precisely fabricated chassis that maintain perfect alignment of components even under extreme conditions. These systems often require specialized RF shielding and thermal management features integrated directly into the chassis design.

Missile and Guidance Systems

Precision-guided systems demand chassis components manufactured to exacting tolerances. These applications highlight the critical nature of custom chassis fabrication, where even minor deviations can impact system performance and reliability.

The common thread across these applications is the demand for uncompromising quality, precision, and reliability. When components are destined for mission-critical systems, there is zero tolerance for failure.

Quality Standards and Compliance Requirements

The defense and aerospace industries operate under rigorous quality standards that directly impact chassis fabrication processes:

- AS9100 Certification: This aerospace-specific extension of ISO 9001 establishes comprehensive quality management system requirements.

- NADCAP Accreditation: The National Aerospace and Defense Contractors Accreditation Program establishes standards for special processes like chemical processing, heat treatment, and non-destructive testing.

- ITAR Compliance: International Traffic in Arms Regulations govern the export and import of defense-related materials and services.

- First Article Inspection: This rigorous verification process ensures that the first production unit meets all engineering requirements before full production begins.

Meeting these standards requires significant investment in quality systems, personnel training, and specialized equipment. However, these investments are essential for manufacturers serving the defense and aerospace sectors, where component failure can have catastrophic consequences.

Emerging Trends Shaping the Future

Several significant trends are reshaping the custom chassis fabrication landscape:

Advanced Materials Adoption

The industry is seeing increased use of specialized aluminum alloys, composite materials, and hybrid structures. These advanced materials offer improved strength-to-weight ratios, enhanced thermal properties, and better vibration damping characteristics.

Design for Thermal Management

As electronic systems become more powerful and compact, thermal management has become a primary design consideration. Modern chassis designs incorporate sophisticated cooling features like integrated heat pipes, liquid cooling channels, and optimized airflow paths.

Automation and Robotics Integration

Automated material handling, robotic welding, and computer-controlled inspection systems are becoming standard in advanced fabrication facilities. These technologies improve consistency, reduce labor costs, and enable 24/7 production capabilities.

Sustainability Initiatives

Environmental considerations are increasingly influencing chassis fabrication processes. This includes more efficient material utilization, reduced energy consumption, and the implementation of cleaner finishing processes that minimize environmental impact.

Digital Manufacturing Ecosystems

The integration of design software, production equipment, quality systems, and business processes into cohesive digital ecosystems represents perhaps the most transformative trend. This approach enables unprecedented levels of process control, traceability, and continuous improvement.

Specialized Processes in Modern Chassis Fabrication

The evolution of custom chassis fabrication has been marked by the refinement of specialized processes that enable exceptional performance in the final product. Among these specialized techniques, dip brazing and brass milling stand out for their importance in creating high-performance chassis components.

Dip brazing has become a cornerstone process for creating structurally sound, thermally conductive chassis assemblies. This joining method creates nearly seamless connections between aluminum components, facilitating thermal transfer while maintaining structural integrity. For thermal management applications in particular, the continuous metallurgical bond created through dip brazing offers significant advantages over mechanical fastening methods.

Similarly, brass milling capabilities provide options for applications requiring specific electrical or thermal properties. While less common than aluminum in aerospace applications, brass components offer excellent corrosion resistance and unique electrical characteristics that make them valuable for specific interconnect and grounding applications within complex chassis assemblies.

Ready to Explore Custom Chassis Solutions?

Whether you’re developing new defense systems or upgrading aerospace components, working with experienced chassis fabrication specialists ensures your projects meet the highest standards. Contact our team today to discuss your custom chassis requirements.