- The Material That Won Aerospace

- How CNC Changed Everything

- The Automation Advantage

- Why 5-Axis Matters for Complex Geometries

- The Domestic Manufacturing Imperative

- Aluminum's Sustainability Edge

- What High-Speed Machining Enables

- The NAMF Difference in Defense Manufacturing

- Engineering Support That Makes the Difference

- Looking Forward

- Why Aluminum Milling Service Matters Now

- Frequently Asked Questions

Key Takeaways

- Aluminum CNC milling delivers the precision, speed, and reliability that defense and aerospace contractors need, with tolerances as tight as ±0.0005 inches and 75% labor reduction through automation.

- Domestic suppliers with full in-house capabilities reduce supply chain vulnerabilities for defense contractors working with over 12,000 tier-2 and tier-3 suppliers on average.

- The aerospace aluminum market is growing from $7.17 billion in 2025 to $10.08 billion by 2034, with North America commanding 35% market share driven by defense sector demand.

The defense supply chain has a problem. And aluminum might solve it.

Global military spending hit $2.44 trillion in 2023, with the United States commanding 40% of that total. But money alone doesn’t manufacture precision components. The real constraint is finding domestic suppliers who can deliver complex aluminum parts with the speed and reliability that defense spending demands.

That’s where an aluminum milling service becomes strategic rather than just technical.

The Material That Won Aerospace

Aluminum owns the aerospace market. It’s expected to grow from $7.17 billion in 2025 to $10.08 billion by 2034. North America leads with 35% market share, driven by advanced aerospace manufacturing and a robust defense sector.

The reasons are fundamental. Aluminum weighs one-third as much as steel while maintaining structural integrity. It resists corrosion naturally. It conducts electricity better than most metals. And it machines beautifully.

But material properties only matter if you can manufacture at scale.

Defense contractors face a different calculus than commercial manufacturers. They need ITAR compliance. They need traceable supply chains. They need vendors who understand MIL-SPEC requirements without lengthy explanations.

Most importantly, they need speed without sacrificing precision.

How CNC Changed Everything

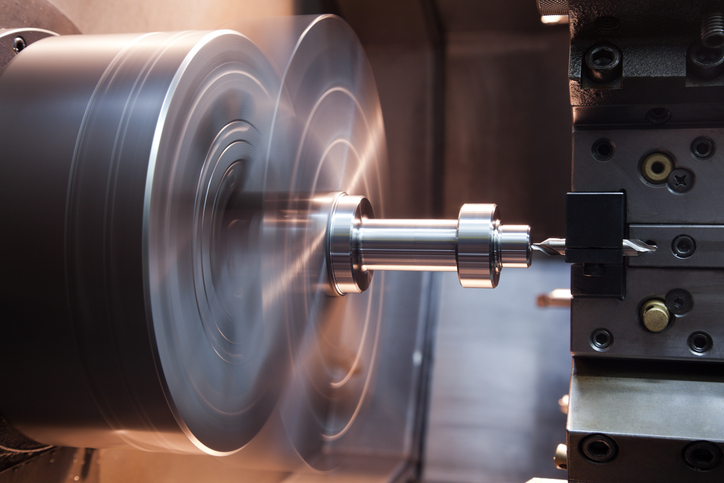

Traditional milling relied on human operators making real-time adjustments. Skilled, yes. Scalable, no.

CNC machining automated what was once manual. Computer Numerical Control turns digital designs into physical parts with repeatability that human hands can’t match. The technology commanded 66.56% of the precision manufacturing market in 2024, advancing at 8.59% annually through 2030.

The precision is remarkable. CNC tools guarantee tolerances as close as ±0.0005 inches on milled features. For aerospace and defense applications where components must perform in extreme conditions, that precision becomes non-negotiable.

But precision metal cutting alone doesn’t solve the supply chain problem.

The Automation Advantage

Modern CNC operations run differently than they did even five years ago. Robotically-controlled pallet systems allow machines to operate continuously. Tool presetters and on-machine gauging turn individual spindles into unattended production cells.

The efficiency gains are substantial. Factory shops can reduce labor hours per machine by up to 75% with effective automation. Some operations achieve 90% spindle uptime running 24/7, cutting unit labor time in half. This level of efficiency separates leading metal fabrication companies from conventional machine shops.

For defense contractors managing tight deadlines and tighter budgets, this matters more than any technical specification.

We’ve invested heavily in this infrastructure at NAMF. Our Fairfield and Ronkonkoma facilities house 18 vertical and 2 horizontal milling machines, all integrated with robotically-controlled palletech systems. This setup allows us to maintain production velocity without compromising the precision that defense applications demand.

Why 5-Axis Matters for Complex Geometries

Standard 3-axis CNC machines move cutting tools along X, Y, and Z axes. They work well for straightforward geometries. But aerospace components rarely feature straightforward geometries.

5-axis machines add rotational capabilities. The cutting tool can approach the workpiece from virtually any angle. Complex parts that once required multiple setups and fixtures can now be completed in a single operation.

The benefits cascade. Fewer setups mean fewer opportunities for error. Single-setup production maintains tighter tolerances. And production time drops dramatically.

For components like turbine housings, avionics enclosures, or ruggedized chassis, 5-axis capability transforms what’s possible. We’ve seen parts that would have required three separate operations and multiple vendor handoffs completed start-to-finish in our facility.

That’s the advantage of vertical integration. Our military machining expertise extends across all complexity levels, from simple brackets to intricate multi-feature assemblies.

The Domestic Manufacturing Imperative

The January 2024 National Defense Industrial Strategy identified a mounting challenge. The Department of Defense depends on adversarial sources for critical materials. These suppliers could cut off U.S. access during geopolitical tensions.

Supply chain resilience moved from operational concern to strategic imperative.

An average aerospace OEM works with over 200 tier-1 suppliers and 12,000 tier-2 or tier-3 suppliers. That complexity creates vulnerability. Each additional vendor introduces potential delays, quality inconsistencies, and communication friction.

Defense contractors are consolidating their supplier base. They’re prioritizing domestic manufacturers with comprehensive capabilities. They’re looking for partners who can handle everything from raw material procurement through finished assembly.

We built NAMF around that model. Our turnkey approach means clients get complete solutions from a single source. Material purchasing, CNC milling, dip brazing, finishing, and assembly all happen in-house. One point of contact. One quality system. One delivery schedule.

For defense applications, that simplicity becomes a strategic advantage. Our military fabrication approach integrates seamlessly with dip-brazed products, creating ruggedized enclosures that meet the most demanding specifications.

Aluminum’s Sustainability Edge

Environmental considerations are reshaping manufacturing decisions. Even in defense applications, sustainability matters.

Aluminum delivers here too. Recycling aluminum requires about 5% of the energy needed to produce new aluminum. As aerospace companies face pressure to reduce emissions, aluminum’s recyclability strengthens its position.

The material itself performs better with age in some applications. Properly treated aluminum alloys can last decades in service, reducing replacement cycles and total lifecycle costs.

These factors matter less for one-off prototypes. But for production runs measured in hundreds or thousands of units, sustainability translates directly to cost efficiency.

What High-Speed Machining Enables

Aerospace applications often involve substantial material removal. Some components start as solid aluminum blocks and end up 95% lighter after machining. That’s not a typo. Integrated structures can require removing 95% of raw material.

High-speed milling makes this economically viable. Modern machines operate at spindle speeds up to 25,000 RPM with correspondingly high feed rates. What once took hours now takes minutes.

The speed advantage compounds across production runs. A part that takes 20% less machine time allows 25% more parts per shift. Multiply that across dozens of components and hundreds of units, and the capacity difference becomes substantial.

We’ve optimized our processes around these capabilities. Our machine selection, tooling strategies, and automation systems work together to maximize throughput without sacrificing surface finish or dimensional accuracy.

Speed and precision aren’t trade-offs. They’re complementary when the system is properly designed.

The NAMF Difference in Defense Manufacturing

We’ve been manufacturing to the highest standards since 1979. Over four decades, we’ve built capabilities specifically around defense and aerospace requirements.

Our certifications reflect that focus. AS9100D certification demonstrates our quality management systems meet aerospace standards. NADCAP accreditation validates our special processes. ITAR registration enables us to handle controlled technical data.

These aren’t just credentials. They’re operational realities that shape how we approach every project.

Our dual-facility structure provides redundancy and scalability. The Fairfield, NJ headquarters houses our primary CNC operations and dip brazing capabilities. Our Ronkonkoma, NY facility (New Age Precision Manufacturing) expands our capacity and provides geographic diversification.

For defense contractors, this matters. Supply continuity can’t depend on a single facility. Our distributed operations reduce risk while maintaining consistent quality standards across locations.

Engineering Support That Makes the Difference

Technical capability is table stakes. What separates strategic partners from transactional vendors is collaborative engineering support.

We work with clients to optimize designs for manufacturability. Small changes in geometry or tolerance allocation can dramatically impact production efficiency without affecting performance. Our engineering team brings decades of manufacturing experience to these discussions.

Design for manufacturability isn’t about compromising specifications. It’s about achieving required performance through the most efficient production path.

This collaboration starts early. The best outcomes happen when manufacturing input shapes design decisions rather than reacting to completed drawings. We’ve helped clients refine component designs that reduced production time by 30% while improving structural performance.

That’s the value of experience applied proactively.

Looking Forward

The aluminum CNC milling landscape continues evolving. AI-driven tool path optimization is making programming more efficient. Predictive maintenance reduces unplanned downtime. Advanced workholding systems enable even more complex geometries in single setups.

We’re investing in these technologies as they mature. But technology alone doesn’t create value. It’s how you integrate new capabilities into existing processes that determines competitive advantage.

The defense and aerospace sectors will continue demanding more. Tighter tolerances. Faster delivery. More complex geometries. Better traceability.

Aluminum CNC milling, executed with the right combination of equipment, expertise, and operational discipline, meets those demands.

Why Aluminum Milling Service Matters Now

Defense contractors can’t afford supply chain vulnerabilities. Aerospace manufacturers can’t accept quality compromises. Both industries are consolidating around suppliers who demonstrate comprehensive capabilities and consistent performance.

The aluminum advantage is well established. The CNC automation revolution is well underway. What’s changing is the urgency around domestic manufacturing partnerships that can deliver both.

We’ve built NAMF specifically for this moment. Full in-house capabilities. Proven defense and aerospace experience. Advanced automation infrastructure. Geographic redundancy. And the engineering expertise to support complex projects from concept through production.

The defense supply chain problem is real. But so is the solution.

Aluminum CNC milling, executed with precision and backed by decades of specialized experience, provides defense contractors and aerospace manufacturers with the reliability they need and the speed they demand.

That’s not marketing language. That’s operational reality.

Partner With NAMF for Components

When your project demands precision, speed, and absolute reliability, NAMF delivers. Our aluminum milling service combines four decades of defense and aerospace expertise with cutting-edge automation and full in-house capabilities.