- The Contract Manufacturing Revolution

- Industry Applications Driving Growth

- Strategic Advantages That Matter

- Navigating Partnership Challenges

- The Manufacturing Capacity Crisis

- Partnership Selection Criteria

- Project Management Excellence

- The Future of Manufacturing Partnerships

- Contract Manufacturing Services Selection

- Frequently Asked Questions

Key Takeaways

- Contract manufacturing services enable companies to access specialized expertise and advanced capabilities without massive capital investments, creating competitive advantages through strategic partnerships.

- The aerospace and defense market’s projected growth to $1,388 billion by 2030 creates unprecedented demand for precision fabrication partners who can deliver quality components on accelerated timelines.

- Successful partnerships require careful evaluation of technical capabilities, quality certifications, and cultural alignment to ensure long-term manufacturing success and supply chain resilience.

Manufacturing partners hold the keys to your success. The aerospace and defense market reached $750 billion in 2022. By 2030, it will hit $1,388 billion. That represents 8.2% annual growth, creating massive opportunities for companies that understand strategic partnerships.

We see this transformation daily. Companies that once built everything in-house now depend on specialized manufacturers for competitive advantage. The shift happened because manufacturing complexity exploded while margins compressed. Building internal capabilities for every component became economically impossible.

The Contract Manufacturing Revolution

Contract manufacturing transforms how companies approach production. Instead of investing millions in equipment and expertise, businesses partner with specialists who have already mastered specific processes. The model works through collaborative relationships. Contract manufacturing services provide designs and specifications.

Manufacturing partners provide quotes, capabilities, and delivery timelines. When outsourcing costs less than internal production, partnerships begin.

Four distinct types dominate the landscape:

- Private Label Manufacturing handles complete product production to specification. The hiring company provides requirements, receives finished products ready for market.

- Individual Component Manufacturing creates specific parts within larger assemblies. This approach works when specialized processes like dip brazing or precision fabrication exceed internal capabilities.

- Labor/Service Subcontracting manages specialized production aspects. Companies maintain overall control while outsourcing complex operations requiring specific expertise or equipment.

- End-to-End Manufacturing provides comprehensive outsourcing, including design input. Partners contribute engineering support, process optimization, and manufacturing execution.

Industry Applications Driving Growth

Real applications span every sector. Coffee companies outsource cultivation and processing. HVAC contractors utilize sheet-metal fabricators for custom enclosures. Pharmaceutical companies outsource drug development to specialized laboratories.

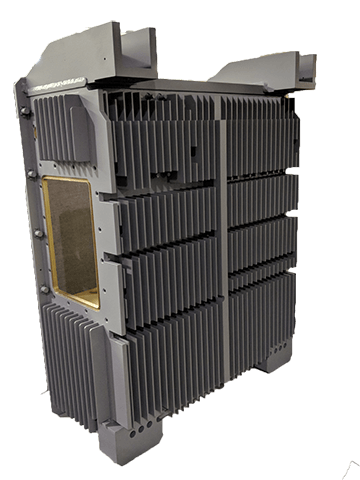

Defense and aerospace applications showcase the model’s power. These industries demand precision-engineered components meeting stringent specifications. Internal development would require massive capital investments and years of capability building. We work with defense contractors requiring ruggedized enclosures for mission-critical applications. These projects demand ITAR compliance, specialized materials knowledge, and processes like aluminum dip brazing that few manufacturers master.

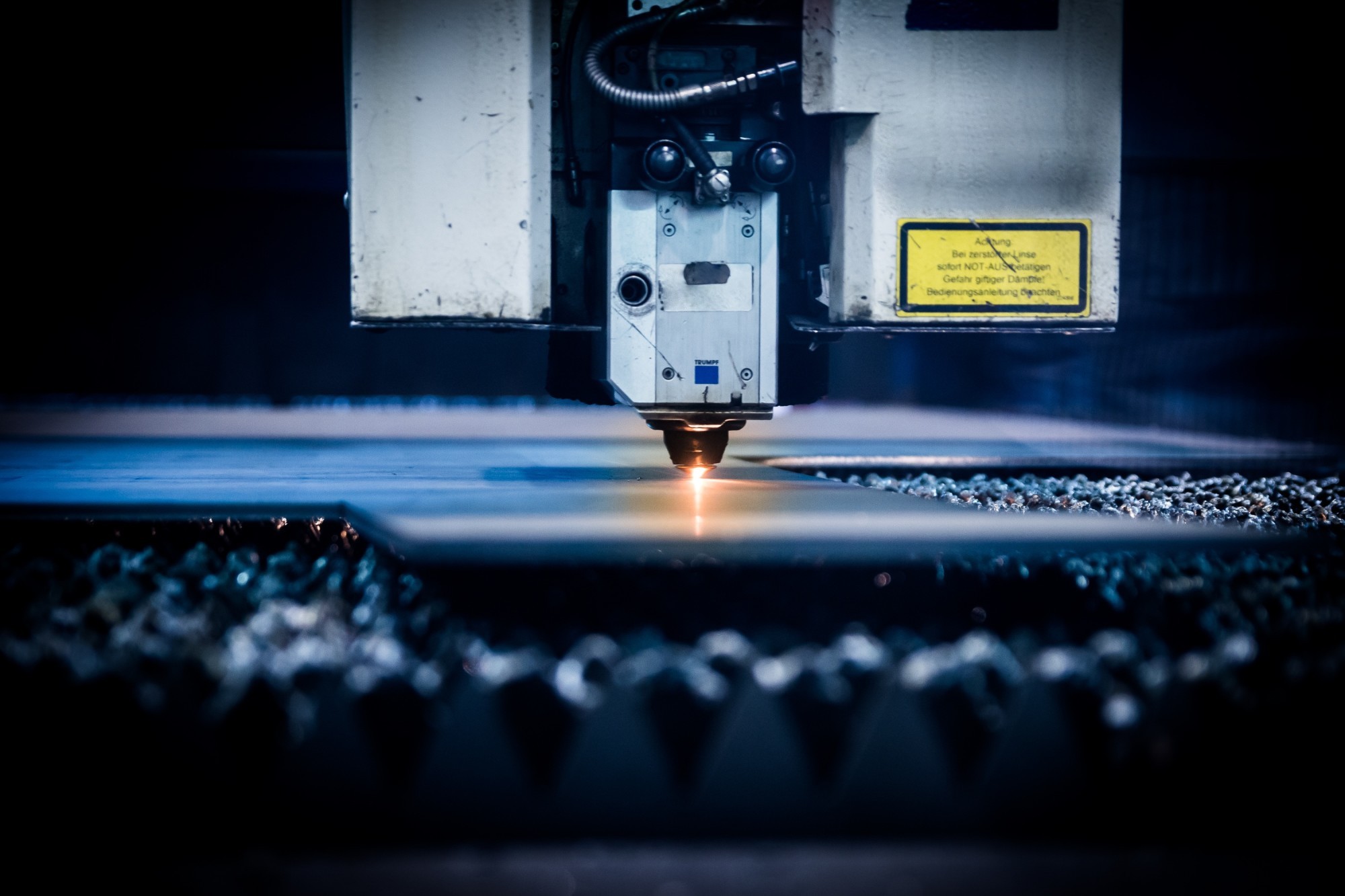

Advanced manufacturing processes including 5-axis milling enable complex geometries that traditional methods cannot achieve. The complexity becomes clear when examining supply chains. An average US commercial aerospace OEM works with more than 200 tier 1 suppliers and 12,000 tier 2 or tier 3 suppliers. This ecosystem requires specialized partners at every level.

Strategic Advantages That Matter

Contract manufacturing delivers advantages that internal production cannot match.

- Specialized Expertise Access provides immediate capability without development time. Partners invest years mastering specific processes, materials, and applications. Companies gain this expertise instantly through partnerships. Cost savings exceed simple labor arbitrage. Avoided capital investments, reduced overhead, and shared equipment costs create substantial advantages. Partners spread fixed costs across multiple clients, reducing per-unit expenses.

- Accelerated Time-to-Market eliminates capability development delays. While competitors build internal processes, partnered companies begin production immediately. Scalability becomes effortless. Partners handle volume fluctuations without internal capacity constraints. Peak demand gets managed through existing capabilities rather than emergency hiring or equipment purchases. Modern horizontal milling operations provide exceptional surface finishes and dimensional accuracy.

- Enhanced Reliability emerges from partner specialization. Dedicated focus on specific processes creates superior quality outcomes compared to divided internal attention.

Competitive advantages multiply for smaller businesses. Access to enterprise-level capabilities without enterprise-level investments levels competitive playing fields.

Navigating Partnership Challenges

Contract manufacturing creates challenges requiring careful management. Finding suitable partners demands extensive evaluation. Technical capabilities, quality systems, and cultural alignment must match project requirements. Due diligence becomes critical for success.

Reduced production control requires different management approaches. Clear specifications, regular communication, and performance metrics become essential partnership elements. Internal knowledge development slows when outsourcing critical processes. Companies must balance partnership benefits against capability retention needs.

Intellectual property security requires comprehensive protection. Contracts must address confidentiality, ownership rights, and technology transfer limitations. Supply chain disruptions can impact multiple clients simultaneously. Partner stability and backup planning become crucial considerations.

The Manufacturing Capacity Crisis

Current market conditions intensify partnership importance. The open-order backlog would take 13 years to address assuming 2023 delivery rates. This creates unprecedented pressure on companies to find capable manufacturing partners.

Supply chain recovery has stalled for many companies. Traditional approaches no longer work when demand exceeds capacity by such margins. Smart companies respond by securing partnerships with specialized manufacturers who can provide consistent delivery and quality. The alternative involves waiting years for internal capacity development while competitors capture market share.

We see this urgency in defense and aerospace applications where program timelines cannot accommodate manufacturing delays. Companies that established partnerships years ago maintain competitive advantages over those still building internal capabilities.

Partnership Selection Criteria

Successful contract manufacturing requires strategic partner selection.

Technical capabilities must match project requirements exactly. Generic manufacturing skills rarely suffice for specialized applications. Partners need demonstrated expertise in specific processes, materials, and industry standards. Production of custom CNC parts requires sophisticated equipment and skilled operators to meet exacting tolerances. Quality systems become non-negotiable. Certifications like AS9100, NADCAP, and ISO standards indicate systematic quality approaches. Defense applications require ITAR compliance and security clearances.

Financial stability ensures partnership longevity. Partners must maintain capabilities through economic cycles and industry fluctuations. Cultural alignment affects collaboration quality. Partners must understand customer priorities, communication preferences, and business practices.

Geographic considerations impact logistics, communication, and oversight. Proximity enables better collaboration but should not override capability requirements.

Project Management Excellence

Effective project management determines partnership success.

Clear specifications eliminate ambiguity. Detailed drawings, material requirements, and performance standards prevent misunderstandings that create delays and quality issues. Regular communication maintains alignment. Scheduled reviews, progress updates, and issue resolution processes keep projects on track.

Performance metrics provide objective evaluation criteria. Quality standards, delivery schedules, and cost targets create accountability frameworks. Documentation systems track progress and maintain records. Digital platforms enable real-time visibility into production status, quality results, and delivery schedules.

Contingency planning addresses potential disruptions. Backup suppliers, alternative processes, and risk mitigation strategies prevent single points of failure.

The Future of Manufacturing Partnerships

Contract manufacturing evolution continues accelerating. Digital integration, advanced materials, and automation technologies create new partnership opportunities. Industry 4.0 capabilities enable real-time collaboration between partners and customers. Digital twins, predictive analytics, and automated reporting systems improve partnership effectiveness.

Sustainability requirements drive partnership specialization. Environmental compliance, material traceability, and energy efficiency become partnership selection criteria. Supply chain resilience demands diversified partner networks. Single-source dependencies create unacceptable risks in critical applications.

We invest continuously in advanced capabilities to serve evolving partnership needs. Our facilities integrate the latest CNC machining, dip brazing, and quality control technologies to deliver superior results.

Contract Manufacturing Services Selection

Contract manufacturing decisions require comprehensive analysis. Total cost evaluation extends beyond unit prices. Development costs, quality risks, and opportunity costs must factor into partnership decisions.

Strategic alignment ensures long-term partnership value. Partners must support business objectives rather than simply reducing costs. Risk assessment identifies potential partnership challenges. Technical risks, supply chain risks, and business risks require mitigation strategies.

Comprehensive metal fabrication capabilities spanning multiple processes enable single-source solutions for complex assemblies. Implementation planning ensures smooth partnership transitions. Change management, training requirements, and integration timelines need careful coordination. Success measurement establishes partnership value. Performance metrics, cost savings, and strategic benefits provide objective partnership evaluation.

The manufacturing landscape transformed permanently. Companies that embrace strategic partnerships gain competitive advantages, while those clinging to internal production fall behind. Partnership selection becomes the critical decision determining manufacturing success. Choose partners with proven expertise, quality systems, and strategic alignment.

The future belongs to companies that master manufacturing partnerships. Start building those relationships now.

Ready to Transform Your Manufacturing Strategy?

Partner with NAMF for comprehensive contract manufacturing services that deliver precision, reliability, and competitive advantage. Our proven expertise in defense and aerospace applications ensures your critical projects succeed.