- How CNC Rapid Prototyping Works

- Why Precision Matters More Than You Think

- The Material Flexibility Advantage

- The Cost Reality Behind Defense Innovation

- What This Means for Your Operations

- The Strategic Advantage of In-House Capabilities

- Looking at Industry Momentum

- Making the Transition

- Conclusion

- Frequently Asked Questions

Key Takeaways

- CNC rapid prototyping reduces acquisition time by up to 99% and costs by 97%, transforming traditional military procurement from years to days.

- The technology achieves tolerances as tight as ±0.0005 inches, meeting the precision requirements essential for mission-critical defense and aerospace applications.

- Material flexibility and rapid iteration enable testing of multiple design variations quickly, minimizing financial risk while encouraging innovation in complex systems.

The U.S. Army’s 28th Ordnance Company turned an 18-month acquisition timeline into 5 days. They reduced costs by 97% and acquisition time by 99% using rapid prototyping technologies. This wasn’t a lucky break. This was the result of understanding what CNC rapid prototyping delivers for mission-critical applications.

The global CNC machine market is projected to reach $195.59 billion by 2032, up from $95.29 billion in 2024. That’s a 9.9% compound annual growth rate driven primarily by aerospace, defense, and automotive sectors demanding advanced manufacturing solutions.

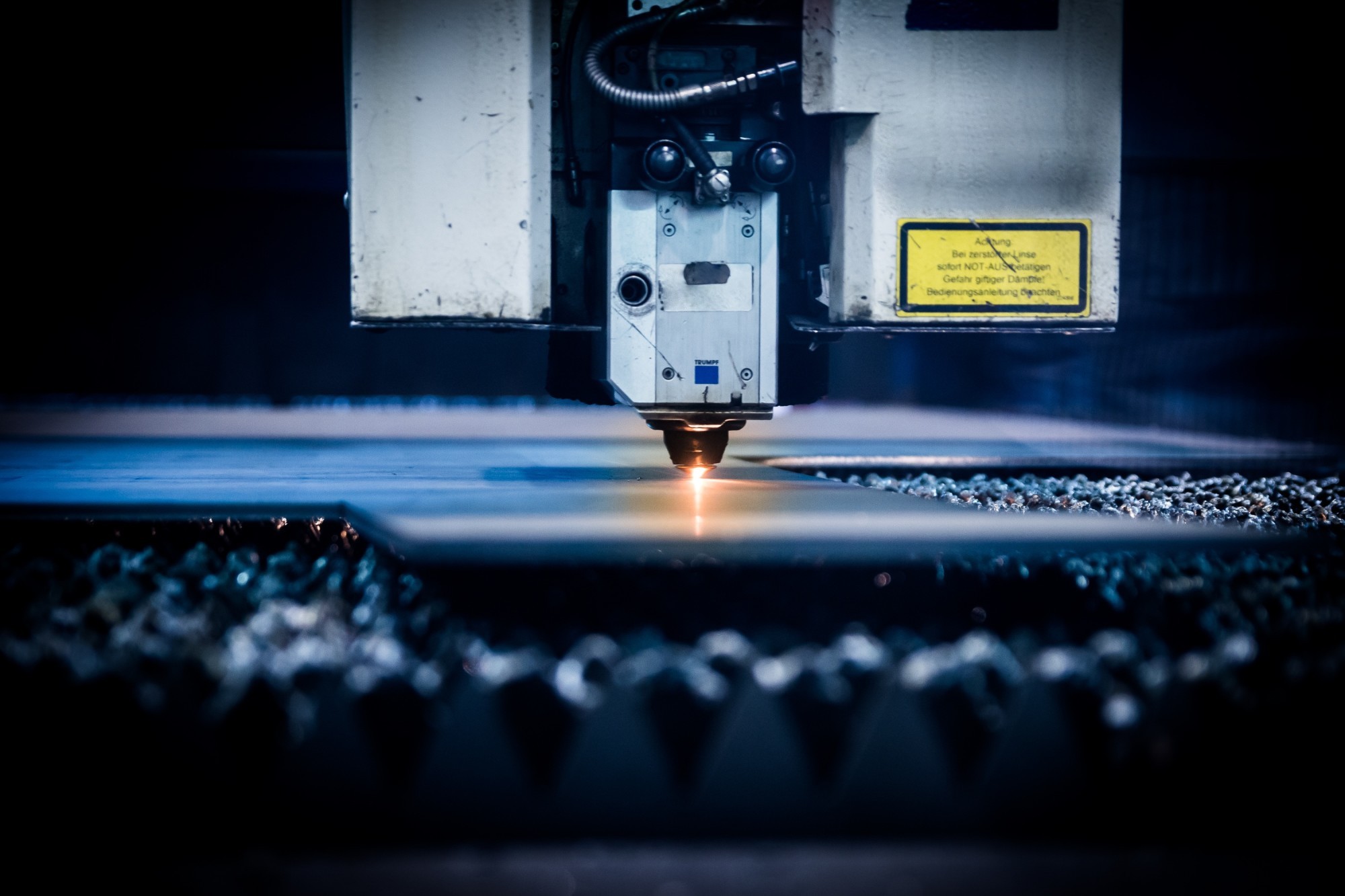

How CNC Rapid Prototyping Works

CNC rapid prototyping is a subtractive manufacturing process that uses computer software to operate machines for fabricating parts from various materials. The process eliminates tooling requirements entirely, translating digital files directly into machined parts within days.

Traditional military procurement often spans years or even decades. CNC rapid prototyping accelerates product development cycles by removing bottlenecks that plague conventional manufacturing approaches.

The technology works with plastics, woods, and metals while meeting tolerances around 0.05mm. For specialized applications, high precision machining achieves tolerances as tight as ±0.0005 inches (0.0127mm), with some techniques reaching 1-5 microns. That level of precision is the baseline requirement for defense and aerospace applications.

CNC Rapid Prototyping Speed and Accuracy

Booz Allen designed, built, and tested an innovative military training solution in 5 days for a major U.S. Army command. The DoD’s rapid prototyping path aims to field prototypes meeting defined requirements within 5 years.

Modern tools enable rapid building, testing, rework, and retesting of prototypes multiple times each day. This capability addresses emerging needs that can’t wait for traditional procurement cycles. Combined with defense machining precision, speed creates an environment where innovation becomes practical.

Why Precision Matters More Than You Think

Aerospace engine components operate in temperature ranges exceeding 1000°C. These components require tolerances measured in microns to maximize efficiency and prevent catastrophic failure. Dimensional accuracy directly impacts safety and performance in mission-critical applications.

The Government Accountability Office notes that prototyping “succeeds” if it provides necessary data—even if the prototype itself doesn’t work. This redefines risk tolerance in defense innovation, allowing you to gather the data needed to make informed decisions.

At NAMF, we’ve worked with defense contractors and aerospace companies for over 40 years, providing contract manufacturing services that ensure reliability when failure isn’t an option. We understand that precision isn’t about hitting arbitrary numbers but about delivering components that perform under the most demanding conditions.

The Material Flexibility Advantage

CNC rapid prototyping works with various materials, allowing you to test different product variations quickly and efficiently. This flexibility becomes critical when you need to optimize components for specific environmental conditions or performance requirements in military machining applications.

The U.S. Navy integrated 3D printers aboard the USS Essex and USS Bataan to enable on-demand production of replacement parts. This reduces reliance on shore-based supply chains—a critical advantage in prolonged deployments or contested maritime environments. Material flexibility combined with rapid production creates operational advantages that extend far beyond the manufacturing floor.

The Cost Reality Behind Defense Innovation

Rapid prototyping enables cost reduction by allowing defense contractors to produce physical models at a fraction of traditional costs. This minimizes financial risk and encourages experimentation with novel designs.

The CNC machine tools market is estimated to grow by $21.9 billion from 2025 to 2029, driven by rising demand for high-precision and multi-axis machining centers. Aerospace and defense remain major consumers of CNC systems, reflecting a fundamental shift in how organizations approach product development.

Breaking Down the Financial Benefits

The benefits of CNC rapid prototyping include:

- Faster production times that compress development cycles from months to days

- Improved durability through iterative testing and refinement

- Increased accuracy that meets or exceeds MIL-SPEC requirements

- Reduced costs by eliminating tooling expenses and minimizing material waste

The technology changes the way weapons and defense systems are designed and produced. You can iterate designs multiple times before committing to full-scale production, reducing the risk of costly errors. Defense CNC prototyping speeds up innovation and fosters collaboration between engineering teams, suppliers, and end users, surfacing potential issues early when they’re less expensive to address.

What This Means for Your Operations

North America’s demand for CNC solutions is particularly driven by aerospace, defense, and automotive sectors. You’re operating in an environment where your competitors are adopting these technologies. The question isn’t whether to integrate CNC rapid prototyping into your workflow but how quickly you can do it effectively.

Integration Considerations

Successful CNC rapid prototyping integration requires understanding several key factors:

- Design for Manufacturability (DFM): Engineering practices aimed at simplifying manufacturing to reduce costs and improve quality become essential when iterating rapidly.

- First Article Inspection (FAI): Processes that verify newly produced parts meet all engineering and design specifications before full production begins protect you from scaling problems.

- ITAR Compliance: International Traffic in Arms Regulations govern the export and import of defense-related materials and information. Vendors must comply to work with defense clients.

At NAMF, we maintain rigorous quality control processes and meet the exacting standards required by defense and aerospace clients. Our ITAR compliance, AS9100 certification, and NADCAP accreditation ensure regulatory alignment across all projects.

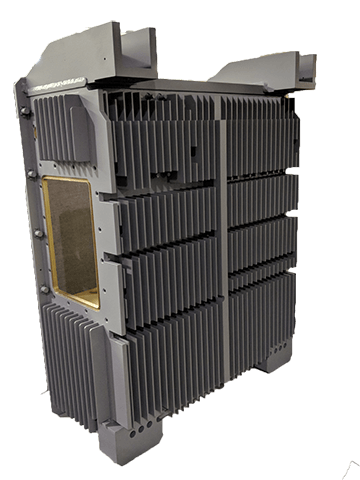

The Strategic Advantage of In-House Capabilities

We offer fully integrated dip brazing services, CNC machining, and precision metal fabrication—all under one roof. This ensures streamlined production, consistent quality, and reduced lead times. Our dual manufacturing facilities in Fairfield, NJ, and Ronkonkoma, NY, enhance operational capacity and flexibility.

You get increased assurance of continuity and scalability when you work with a partner who controls the entire production process. Single-source suppliers eliminate coordination headaches and reduce points of failure.

Beyond Basic Fabrication

We specialize in ruggedized enclosures and components that meet the stringent requirements of military fabrication and aerospace applications. Our expertise in aluminum dip brazing is rare and valued in sectors where reliability is non-negotiable.

The combination of niche expertise, vertical integration, and specialization in high-stakes industries equips us to deliver precision, reliability, and speed in projects where failure isn’t an option. We also offer collaborative engineering support to refine designs for manufacturability, durability, and performance, helping you optimize components before production begins.

Looking at Industry Momentum

The trends shaping CNC rapid prototyping in defense and aerospace point toward continued acceleration:

Automation and AI Integration: Advanced technologies make it easier to program complex parts, optimize tool paths, and predict maintenance needs before they become critical issues.

Sustainability Emphasis: Organizations increasingly focus on environmentally friendly processes and materials, including chem film coating alternatives that reduce environmental impact while maintaining corrosion resistance.

Workforce Development: Continuous training and development programs ensure teams remain adept at utilizing state-of-the-art technologies and manufacturing techniques.

These trends create opportunities for organizations willing to invest in capabilities that position them at the forefront of manufacturing innovation.

What Separates Leaders from Followers

Organizations that thrive in this environment share common characteristics. They invest in advanced technologies like 5-axis machining to improve manufacturing processes, reduce setup operations, and simplify fixturing. They pursue and maintain industry certifications like AS9100D and NADCAP to demonstrate commitment to quality and compliance with aerospace and defense industry standards.

They implement rigorous quality control measures to ensure precision, durability, and compliance with industry standards. Likewise, they treat rapid prototyping as a strategic capability rather than a tactical tool.

Making the Transition

The data shows that organizations adopting CNC rapid prototyping gain measurable advantages in speed, cost, and quality. The U.S. Army demonstrated a 99% reduction in acquisition time and 97% cost savings—real operational improvements.

At NAMF, we’ve been at the cutting edge of metal fabrication since 1979, working with sheet metal fabricators and advanced manufacturing specialists. We’ve watched technologies evolve and helped clients navigate transitions from traditional to advanced manufacturing approaches.

What You Need to Know

CNC rapid prototyping delivers the most value when you partner with suppliers who understand your industry’s specific requirements. Defense and aerospace applications demand more than basic fabrication capabilities.

You need suppliers who maintain compliance with ITAR regulations, hold relevant certifications, and have proven track records delivering precision-engineered solutions to mission-critical projects. You need partners who offer collaborative engineering support, not just manufacturing services.

Conclusion

CNC rapid prototyping has transformed how defense and aerospace organizations approach product development. The technology delivers measurable advantages in speed, cost, and precision—reducing acquisition times by up to 99% while maintaining the tight tolerances mission-critical applications require.

Success requires partnering with suppliers who understand your industry’s specific requirements and maintain the certifications, capabilities, and expertise necessary for defense and aerospace applications. The question isn’t whether to adopt CNC rapid prototyping but how to integrate it effectively into your operations.

Partner With NAMF for CNC Rapid Prototyping Excellence

Ready to accelerate your product development with proven precision manufacturing? Contact NAMF today to discuss your project requirements and discover how our comprehensive capabilities can support your mission-critical applications.