Most aerospace suppliers never achieve this level of brazing certification. Nadcap represents something different in aerospace manufacturing. While many suppliers can meet basic quality standards, only exceptional aerospace suppliers achieve Nadcap accreditation and the specialized brazing certification that comes with it. The difference matters more than most people realize.

What Makes Nadcap Different

Nadcap, which was previously the National Aerospace and Defense Contractors Accreditation Program, is a global cooperative accreditation program for aerospace engineering, defense, and related industries. But the name only tells part of the story.

This industry-managed approach to conformity assessment focuses on special processes and products in aerospace manufacturing. We’re talking about the critical processes that determine whether components perform under extreme conditions.

Welding and brazing sit at the heart of these special processes. These aren’t simple manufacturing steps. They’re precision operations where microscopic variations can mean the difference between mission success and catastrophic failure.

The stakes demand exceptional brazing certification standards.

Why Brazing Requires Special Attention

Nadcap brazing involves joining metal parts using filler materials at high temperatures. In aerospace applications, these joints must withstand incredible stress, temperature variations, and environmental challenges.

The purpose of flux in brazing is to prevent the formation of oxide compounds, which can lead to complications such as porosity, discontinuous braze, and poor quality. Like fusion welding, brazing involves the use of gas and torches to create heat needed to melt filler material.

Every variable matters. Temperature control, timing, material preparation, and environmental conditions all influence the final result.

Standard quality control catches obvious problems. Brazing certification ensures suppliers can consistently manage the invisible factors that determine long-term reliability.

The Trust Factor

Large aerospace and defense contractors face a complex challenge. They need suppliers who can deliver consistent quality without constant oversight. Historically, these contractors sent individual personnel to audit suppliers. This approach worked but created inefficiencies and inconsistencies across the supply chain.

Brazing certification changes this dynamic. As one industry expert noted, Nadcap certification is “an unspoken way for them to say, ‘We trust you as a company'”.

This trust translates into real business advantages. Nadcap approved suppliers often receive preference in contract awards, face fewer quality audits, and build stronger long-term relationships with major contractors.

The NAMF Approach to Excellence

At New Age Metal Fabricating, we understand what brazing certification represents. Since 1979, we’ve built our reputation on delivering precision-engineered components for defense and aerospace applications.

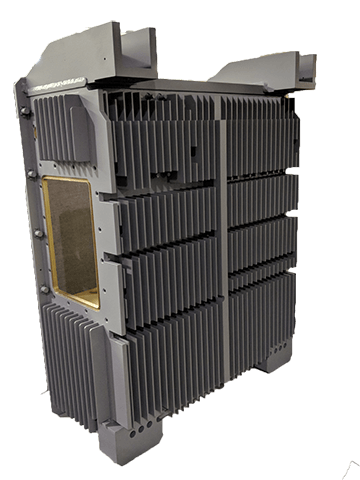

Our specialization in aluminum brazing aligns perfectly with Nadcap’s focus on special processes. Dip brazing requires precise temperature control, careful material preparation, and in-depth understanding of metallurgical principles. We’ve made pursuing brazing certification a key short-term goal because we recognize its value to our clients. This certification represents more than a quality standard. It demonstrates our commitment to the exceptional performance that aerospace applications demand.

Our dual facilities in Fairfield, NJ, and Ronkonkoma, NY, provide the capacity and redundancy that major contractors value. Combined with our full in-house capabilities, we offer the complete solution that simplifies supply chain management.

Beyond Certification

Brazing certification opens doors, but it’s what suppliers do with that access that matters most. The aerospace industry values suppliers who understand both the technical requirements and the broader mission context. Components we fabricate become part of systems that protect national security, enable scientific discovery, and push the boundaries of human capability.

This perspective shapes how we approach every project. Quality isn’t just about meeting specifications. It’s about delivering components that perform flawlessly when failure isn’t an option. Our collaborative engineering support helps clients optimize designs for both performance and manufacturability. This partnership approach creates better outcomes for everyone involved.

The Future of Aerospace Manufacturing

Aerospace manufacturing continues evolving toward higher precision, greater reliability, and more complex applications. Brazing certification provides the foundation for suppliers to participate in this evolution.

We see this certification as part of our broader commitment to staying at the forefront of aerospace manufacturing capabilities. Our investment in advanced technologies, workforce development, and quality systems positions us to meet the challenges ahead.

The aerospace industry needs metal fabrication companies that can grow with increasing demands. Brazing certification demonstrates that capability while providing the framework for continuous improvement.

For defense contractors and aerospace companies seeking reliable partners, brazing certification offers a clear signal. It identifies precision fabricating suppliers who have proven their ability to manage the special processes that determine mission success.

That’s the level of partnership we’re building at NAMF. One precision component at a time.

Key Takeaways

- Brazing certification through Nadcap separates elite aerospace suppliers from standard manufacturers by ensuring precision in critical processes.

- Nadcap approved suppliers gain contractor trust, receive contract preferences, and face fewer quality audits.

- Aluminum brazing requires specialized knowledge and precise control that only certified suppliers can consistently deliver.

Ready to Work with Nadcap-Pursuing Specialists?

At New Age Metal Fabricating, we’re actively pursuing brazing certification to better serve our aerospace and defense clients. Our decades of experience in precision aluminum brazing and commitment to quality excellence make us the ideal partner for your critical applications.