- The Setup Time Problem Nobody Talks About in 3 Axis vs 5 Axis Milling

- When 3-Axis Makes Perfect Sense

- The Precision Advantage You Can Measure

- The Real Cost Calculation

- Market Forces Reshaping the Decision

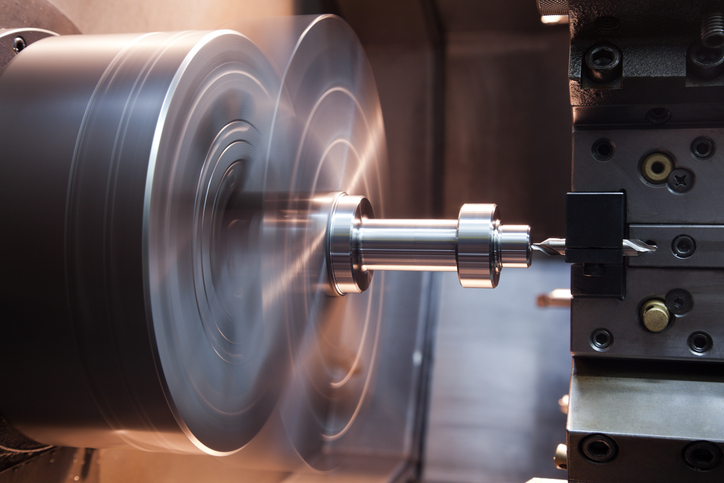

- The Geometry Question

- Programming and Operator Considerations

- Material Handling and Surface Finish

- How We Approach the Decision at NAMF

- Looking Forward

- Making the Right Choice for Your Project

- Frequently Asked Questions

Key Takeaways

- Five-axis systems reduce setup times by approximately 60% and deliver five-fold better precision (±0.005 mm vs ±0.025 mm) compared to 3-axis machines, making them essential for complex geometries with tight tolerances.

- 3-axis milling remains cost-effective for flat surface machining, high-volume standard components, and simple geometries where multiple setups don’t compromise precision requirements.

- Total cost per part—not hourly machine rates—should drive your decision, as 5-axis capability often reduces fixture costs, setup time, and secondary operations for complex components.

The aerospace component sitting on your desk needs five different setups on a 3-axis mill. Each setup adds positioning error. Each re-clamp introduces risk.

Or you could machine it in two setups on a 5-axis system.

We’ve watched this decision play out hundreds of times at NAMF. The math seems simple. 5-axis machines cost more, so you assume they’re only for complex parts. But the real calculation involves setup time, cumulative error, and the hidden costs of multiple operations.

Here’s what the numbers actually tell us.

The Setup Time Problem Nobody Talks About in 3 Axis vs 5 Axis Milling

Every time you unclamp a part, you lose precision. The positioning error is small—around ±0.0002 inches (0.01 mm) per setup. But those errors stack.

Five setups on a 3-axis machine can accumulate ±0.001 inches (0.03 mm) or more.

That’s the difference between a part that meets spec and one that doesn’t. In defense and aerospace work, that’s the difference between a contract and a rejection.

We see this pattern repeatedly: shops using 5-axis systems reduce their setup times by approximately 60% compared to traditional 3-axis operations. Parts requiring 5 to 9 different setups on 3-axis machines get completed in just 2 setups with 5-axis technology.

The time savings compound across production runs.

When 3-Axis Makes Perfect Sense

Understanding the 3 axis vs 5 axis milling debate starts with recognizing that each technology serves distinct purposes in precise machining and manufacturing operations.

You don’t need a 5-axis machine for every job. That’s the first thing we tell clients.

3-axis milling excels at specific applications:

- Flat surface machining: When your part geometry stays on parallel planes

- High-volume standard components: Where setup time becomes negligible per part

- Prototype development: When you need quick turnaround on simple geometries

- Budget-constrained projects: Where part complexity doesn’t justify 5-axis rates

The 3-axis approach uses straightforward linear movements along X, Y, and Z axes. Programming is simpler. Operators are easier to find. Hourly rates stay lower when compared to contract manufacturing services that specialize exclusively in advanced multi-axis operations.

For prismatic parts with features on a few parallel faces, 3-axis remains highly capable and cost-effective.

But the moment your part introduces undercuts, compound angles, or complex contours, the equation changes.

The Precision Advantage You Can Measure

Five-axis machining delivers measurements within ±0.005 millimeters. Traditional 3-axis setups typically achieve ±0.025 millimeters.

That’s a five-fold improvement in precision.

Aerospace suppliers using 5-axis systems report 92% first-pass yield rates when milling turbine blades—a 35% improvement over manual 3-axis processes. Those numbers represent real production efficiency, not marketing claims.

The precision comes from multiple factors:

- Shorter, more rigid cutting tools. Because the machine head or table can tilt to maintain optimal cutting position, you can use shorter tools. Shorter tools resist vibration and deflection better, producing higher quality surface finishes.

- Optimized tool angles. The ability to approach the workpiece from any angle means you can maintain ideal cutting conditions throughout the operation. This matters especially with difficult-to-machine materials.

- Single-setup accuracy. When you eliminate multiple setups, you eliminate the cumulative positioning errors that come with them. This precision becomes crucial when producing custom CNC parts for defense applications requiring exacting specifications.

The Real Cost Calculation

Yes, 5-axis machines have higher upfront costs. The hourly rate looks steeper on paper.

But you need to calculate total cost per part, not hourly machine rates.

Five-axis machining cuts or eliminates intricate fixtures. It reduces setup time dramatically. It minimizes secondary operations. Each of these factors affects your bottom line more than the hourly rate differential.

For complex parts in moderate to high volumes, the total cost per part often ends up lower with 5-axis, despite the more expensive hourly rates.

We’ve seen this pattern across defense and aerospace contracts: the shops that invest in 5-axis capability win bids on complex components because they can deliver tighter tolerances with better repeatability and faster turnaround.

Market Forces Reshaping the Decision

The 5-axis CNC machining centers market is projected to grow by $792.5 million from 2024 to 2028. The global market was valued at approximately $4.2 billion in 2023 and is expected to reach $8.7 billion by 2033.

That growth reflects real demand, particularly in aerospace and defense.

Over 65% of 5-axis applications concentrate in aerospace and automotive manufacturing. These industries demand components with tolerances as tight as 0.002 mm—tolerances that 3-axis systems struggle to achieve consistently.

Global supply chain disruptions are pushing companies to bring complex machining back to North America. The U.S. 5-axis CNC machining services niche is projected to reach approximately $3,417 million in 2025.

Companies want control. They want reduced lead times. They want IP security and agility.

Five-axis capability delivers all of these advantages.

The Geometry Question

Some parts simply cannot be machined effectively on 3-axis systems.

Consider NASA’s Orion bulkhead—a domed surface near the heat shield with pockets normal to the curved surface. You cannot machine that with conventional 3-axis operations. The geometry demands simultaneous multi-axis movement.

Turbine blades. Impellers. Medical implants. Aerospace structural components requiring industrial engraving and intricate surface details. These parts share a common characteristic: complex geometries that require the cutting tool to approach from multiple angles.

When you encounter these geometries, the 3-axis vs 5-axis question answers itself.

But many parts fall into a gray area. They can be machined on 3-axis equipment, but only with multiple setups, custom fixtures, and extended cycle times.

That’s where the decision becomes strategic rather than technical.

Programming and Operator Considerations

The programming complexity of 5-axis systems used to be a major barrier. Not anymore.

Modern CAM software with integrated toolpath verification and collision-avoidance algorithms reduces manual programming interventions by 85%. The systems handle much of the complexity automatically.

Advanced 5-axis models equipped with IoT capabilities now account for nearly 40% of total installations. Businesses adopting connected systems see approximately a two-thirds drop in programming mistakes thanks to AI-driven collision warnings and automatic adjustments for worn tools.

The operator skill requirement remains higher for 5-axis work. But the gap is narrowing as the technology becomes more intuitive and automated.

Material Handling and Surface Finish

Both 3-axis and 5-axis systems can handle aluminum, brass, steel, and other common materials. The choice depends more on part geometry than material properties, though specialized processes like aluminum dip brazing may influence your manufacturing approach for certain assemblies.

But 5-axis systems excel with difficult-to-machine materials by optimizing tool angles. Better tool positioning improves chip evacuation. Enhanced coolant delivery reaches the cutting zone more effectively.

The result: better surface finishes on complex parts, even in challenging materials.

For defense and aerospace applications where surface finish specifications are tight and non-negotiable, this advantage matters.

How We Approach the Decision at NAMF

We maintain both 3-axis and 5-axis capabilities at our Fairfield, NJ and Ronkonkoma, NY facilities. The redundancy gives us flexibility in delivering custom sheet metal fabrication alongside advanced machining. More importantly, it lets us match the right technology to each project.

When you bring us a project, we don’t automatically default to the more expensive option. We analyze the geometry, tolerance requirements, production volume, and timeline.

Sometimes 3-axis is the right answer. Sometimes 5-axis is the only answer. Often, a hybrid approach makes the most sense, using 3-axis for simpler operations and 5-axis for complex features.

Our engineering team works with you to refine designs for manufacturability. This collaboration often reveals opportunities to simplify geometries or adjust tolerances in ways that reduce costs without compromising function.

That’s the value of working with a manufacturer who has in-depth experience in both technologies.

The Certification Factor

When producing military enclosures and defense components with precision sheet metal requirements, certifications validate both capability and reliability.

In defense and aerospace work, capability means nothing without certification.

We hold NADCAP, NAVSEA, and ISO accreditations. Our quality control processes meet the exacting standards these certifications require. When we tell you a part will meet spec, you can trust that commitment.

The certifications also ensure ITAR compliance, critical for defense contractors who need vendors capable of handling controlled technical data.

This combination of advanced machining capability and rigorous quality systems is what defense and aerospace clients actually need. The technology matters. But the systems and processes around that technology matter just as much.

Looking Forward

The trend lines are clear. Five-axis adoption will continue growing, particularly in high-precision industries. Automation and AI integration will make the technology more accessible and efficient.

But 3-axis machining isn’t disappearing. It remains the right choice for a significant percentage of applications.

The key is knowing which technology fits your specific needs—and having access to both when the situation demands it.

Making the Right Choice for Your Project

The 3-axis vs 5-axis decision comes down to a few critical factors:

- Part complexity: Multiple angles and compound curves favor 5-axis. Simple geometries favor 3-axis.

- Tolerance requirements: Tighter tolerances often require 5-axis precision and single-setup accuracy.

- Production volume: High volumes can justify 5-axis investment through reduced cycle times. Low volumes might not.

- Time constraints: Faster turnaround on complex parts typically requires 5-axis capability.

- Total cost per part: Calculate the complete picture, not just hourly machine rates.

You need a manufacturing partner who can evaluate these factors objectively and recommend the approach that serves your project best—even when that means choosing the less expensive option.

At NAMF, we’ve built our reputation on delivering precision-engineered solutions for defense and aerospace applications. We have the technology, the certifications, and the experience to handle complex projects from initial design consultation through final inspection.

If you’re evaluating manufacturing options for precision components, we should talk. We can review your specifications, discuss the optimal approach, and provide a clear cost analysis that accounts for all the factors we’ve covered here.

Contact us to discuss your project requirements and explore how our capabilities can support your manufacturing needs.

Ready to Choose the Right Machining Solution?

Whether your project demands 3-axis efficiency or 5-axis precision, NAMF delivers the expertise and certification your defense or aerospace application requires. Let’s discuss which approach optimizes your specific requirements.