- The Market Reality Behind New Jersey's Fabrication Scene

- What Makes a Fabricator Truly Exceptional

- The Workforce Challenge That Changes Everything

- New Age Metal Fabricating's Unique Position

- The Engineering Support Advantage

- Beyond the Top Three

- The Future of Precision Fabrication

- Frequently Asked Questions

Your next defense contract depends on choosing the right fabricator among New Jersey’s competitive landscape of sheet metal fabricators.

The difference between a successful project and a costly failure often comes down to one decision. Which metal fabricator do you trust with mission-critical components that can’t fail?

New Jersey’s industrial landscape hosts dozens of metal fabricators in NJ. But when aerospace giants and defense contractors need precision parts, they turn to a select few proven metal fabricators with specialized capabilities.

The aerospace and defense industry generated over $955 billion in sales in 2023, marking a 7.1% increase from the previous year. This growth creates intense pressure on fabricators to deliver components that meet increasingly stringent requirements.

Here’s what separates the top sheet metal fabricators from the rest.

The Market Reality Behind New Jersey’s Fabrication Scene

New Jersey sits at the heart of the Northeast’s manufacturing corridor. The state’s proximity to major defense contractors and aerospace companies creates a unique ecosystem of specialized sheet metal fabricators.

But proximity alone doesn’t guarantee quality.

The aerospace and defense segment now represents 30.3% of the sheet metal fabrication market. This concentration means sheet metal fabricators must meet standards that go far beyond typical commercial work.

ITAR compliance has become mandatory for sheet metal fabrication NJ operations. Quality certifications like AS9100D and NADCAP separate qualified suppliers from general fabricators. First Article Inspection processes ensure every component meets exact specifications before production begins.

These requirements create natural barriers to entry. Many sheet metal fabricators simply can’t meet the investment in equipment, training, and certification required for defense and aerospace work.

What Makes a Fabricator Truly Exceptional

You might think advanced equipment defines the best sheet metal fabricators. CNC machines, laser cutters, and press brakes are certainly important.

The real differentiator lies deeper.

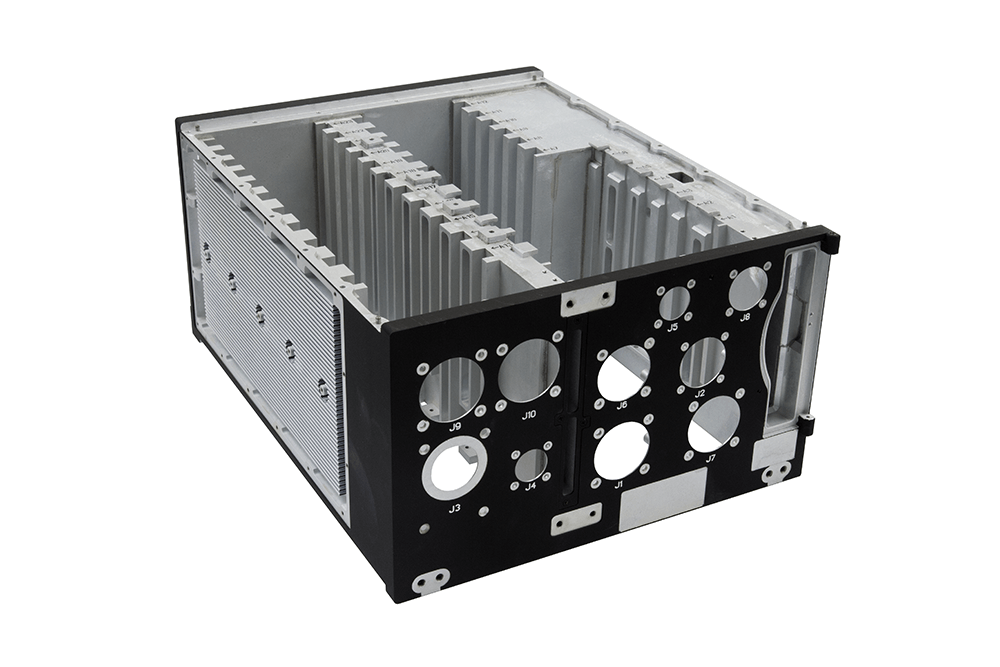

Specialized processes that most sheet metal fabricators can’t offer. Take aluminum dip brazing. This process creates incredibly strong joints by immersing assembled parts in molten salt. The result is a ruggedized enclosure that can withstand extreme conditions.

Most metal fabricators outsource specialized processes like dip brazing. This creates delays, quality control issues, and communication gaps. When your timeline is measured in weeks, not months, these delays become critical.

Vertical integration eliminates these problems. The best sheet metal fabricators bring multiple processes under one roof. CNC machining, metal fabrication, sheet metal punching, and specialized joining processes all happen in the same facility.

This integration creates something valuable: single-point accountability.

When issues arise, and they always do, you have one phone call to make. One team responsible for the entire project. One set of quality standards applied throughout the process.

The Workforce Challenge That Changes Everything

Equipment and processes matter. But skilled workers make the difference between good parts and exceptional ones for sheet metal fabricators.

The American Welding Society predicts a deficit of 400,000 welders by 2024. This shortage affects every aspect of NJ metal fabrication, from basic assembly to complex precision work.

Sheet metal fabricators with experienced, stable workforces gain tremendous advantages. They can take on complex projects that require specialized knowledge. They maintain consistent quality standards across different jobs. Furthermore, they meet deadlines because they’re not constantly training new workers.

The shortage also drives up labor costs. Sheet metal fabricators without skilled workers resort to overtime and rushed production schedules. Quality suffers. Delivery dates slip.

Established sheet metal fabricators with strong workforce development programs sidestep these problems entirely.

New Age Metal Fabricating’s Unique Position

Among New Jersey’s sheet metal fabricators, New Age Metal Fabricating (NAMF) occupies a distinctive position in the defense and aerospace market.

Founded in 1979, NAMF has spent 45 years building capabilities that most sheet metal fabricators can’t match. Their Fairfield, NJ facility houses dip brazing, CNC machining, and precision metal fabrication under one roof.

The dip brazing specialization sets them apart from other sheet metal fabricators. This process creates aluminum assemblies with exceptional strength and thermal conductivity. Perfect for ruggedized enclosures that must function in harsh environments.

Most metal fabricators send dip brazing work to outside suppliers. NAMF performs the entire process in-house, maintaining control over quality and timing.

Their dual-facility approach adds another layer of capability. The Ronkonkoma, NY, location operates as New Age Precision Manufacturing, expanding capacity and providing operational redundancy.

Certifications tell the quality story. NADCAP, NAVSEA, and ISO accreditations demonstrate compliance with the most demanding industry standards. These aren’t easy certifications to obtain or maintain.

ITAR compliance enables work on defense projects with export restrictions. Many metal fabricators avoid ITAR compliance because of the administrative burden. NAMF embraces it as a competitive advantage.

The Engineering Support Advantage

Great sheet metal fabricators don’t just build what you design. They help you design better parts.

Design for Manufacturability (DFM) consultation can save thousands of dollars per project. Small changes in part geometry might reduce machining time by 30%. Material selection adjustments can improve durability while cutting costs.

NAMF’s engineering team works with clients to optimize designs before production begins. This collaborative approach catches potential issues early when changes are inexpensive.

The alternative is discovering problems during production. Redesigns at that stage create delays and cost overruns that can kill project budgets.

Beyond the Top Three

Industry discussions often mention three fabricators when talking about New Jersey’s top capabilities: NAMF, EVS Metal, and Alliance Sheet Metal.

Each brings different strengths to the market. EVS Metal focuses on rapid prototyping and quick-turn production. Alliance Sheet Metal emphasizes architectural and commercial applications.

NAMF’s concentration on defense and aerospace creates deep specialization in applications where failure carries serious consequences. Their ruggedized enclosures protect sensitive electronics in military vehicles, aircraft, and naval systems.

The choice between sheet metal fabricators depends on your specific requirements. But when your application demands the highest levels of precision, reliability, and specialized processes, the field narrows considerably.

Making the Right Choice for Your Project

Selecting among metal fabricators involves more than comparing quotes and delivery times. The right questions reveal capability differences that matter.

- Can they handle your specialized processes in-house? Outsourcing creates delays and quality control challenges. Integrated capabilities provide better control and faster turnaround.

- What certifications do they maintain? Defense and aerospace work requires specific quality standards. Certifications like AS9100D and NADCAP demonstrate proven capability.

- How do they handle engineering support? The best sheet metal fabricators help optimize your designs for manufacturability. This consultation can save significant time and money.

- What’s their workforce stability? Experienced workers produce better results. High turnover creates quality and scheduling problems.

- Can they provide operational redundancy? Multiple facilities or backup processes ensure your project continues even if problems arise.

The Future of Precision Fabrication

New Jersey’s fabrication landscape continues to evolve. Advanced technologies like 5-axis machining and automated quality inspection are becoming standard requirements for sheet metal fabricators.

The sheet metal fabricators that survive and thrive will be those that invest in both technology and people. Equipment alone can’t solve complex manufacturing challenges. Skilled workers using advanced tools create the combination that delivers exceptional results.

Sustainability considerations are also driving changes. Aluminum’s recyclability makes it increasingly attractive for aerospace applications. Sheet metal fabricators with aluminum expertise, particularly in specialized processes like dip brazing, are well-positioned for future growth.

The defense and aerospace markets show no signs of slowing. Geopolitical tensions and technological advancement continue driving demand for precision components.

Your fabricator choice today shapes your competitive position tomorrow. Choose wisely.

Key Takeaways

- Sheet metal fabricators with ITAR compliance and specialized certifications dominate the aerospace and defense market.

- Vertical integration eliminates delays and quality issues by keeping all processes under one roof.

- Skilled workforce stability gives top fabricators significant advantages over competitors struggling with labor shortages.

Ready to Find Your Ideal Fabrication Partner?

The right fabricators can make or break your aerospace or defense project. With mission-critical components on the line, you need a partner with proven capabilities, specialized processes, and unwavering quality standards.