- The Market Reality Behind Vertical Milling Services Growth

- Precision Capabilities That Meet Modern Standards

- The Cost-Efficiency Equation

- Technology Integration Driving Modern Performance

- Industry Trends Shaping Vertical Milling Demand

- Our Approach to Vertical Milling at NAMF

- Looking Forward: Vertical Milling's Role in Modern Manufacturing

- Frequently Asked Questions

Key Takeaways

- Vertical milling services deliver micron-level precision for defense and aerospace components while maintaining lower upfront costs and faster setup times than horizontal configurations.

- CNC-equipped vertical mills dominate the market, offering programmable repeatability, automated tool changes, and real-time monitoring for consistent quality across production runs.

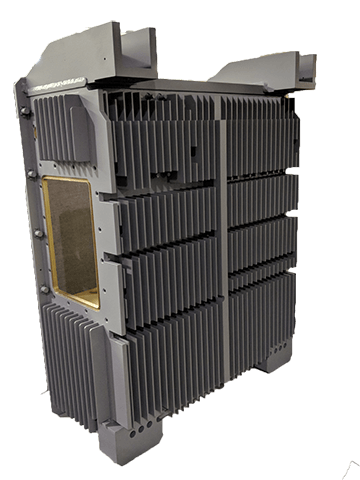

- Integrated manufacturing approaches combine vertical milling with dip brazing, metal fabrication, and finishing services to provide turnkey solutions for defense contractors.

The aerospace and defense milling market continues to grow at 7% annually. That growth isn’t coming from flashy new technologies alone. It’s coming from manufacturers who understand that the right tool for the job often looks surprisingly traditional.

Vertical milling machines represent that intersection of proven reliability and modern precision. While five-axis machines grab headlines, vertical mills continue to dominate production floors across North America, particularly in defense and aerospace applications where tolerances measured in micrometers aren’t optional.

Here’s what’s driving this sustained momentum.

The Market Reality Behind Vertical Milling Services Growth

The vertical milling machine market continues to grow steadily, reflecting reliable demand rather than speculative hype.

North America leads this growth. The driver? Reshoring policies that have directed significant investment toward semiconductor, battery, and defense manufacturing plants. Each of these facilities needs precision machining capabilities, and vertical mills remain the workhorse for many critical operations.

The aerospace and defense segment shows particularly strong growth. This stems from increasing demand for lightweight, high-strength materials and precision parts that meet increasingly stringent specifications, especially in defense machining applications.

CNC Integration Dominates the Landscape

CNC variants account for the majority of the vertical milling market. The reason is straightforward: programmable motion enables repeatability, multi-machine cells, and unattended shifts. These capabilities matter when you’re producing parts where failure isn’t an option.

Modern vertical CNC mills equipped with automatic tool changers dramatically reduce setup downtime compared to manual systems. Precision-ground tool holders maintain tight tolerances, ensuring consistency across production runs in high-volume CNC machining operations.

Precision Capabilities That Meet Modern Standards

Prime contractors impose ±0.0001-inch tolerances on critical titanium and advanced-alloy parts. Meeting these specifications requires machines with superior damping, thermal stability, and adaptive control.

Vertical CNC milling machines deliver tolerances measured in micrometers or ten-thousandths of an inch. In aerospace applications, turbine blade slots machined on vertical CNC mills can achieve ±2 µm positional tolerances, exceeding AS9100D standards and eliminating secondary finishing operations.

These machines also deliver faster cycle times than conventional mills in high-volume production while holding ±0.001″ tolerances. Speed and precision aren’t trade-offs anymore.

Material Processing Across Military Fabrication Applications

Vertical machining centers handle the full range of materials military fabrication manufacturers work with:

- Aluminum roughing with high-power spindles ensures efficient material removal

- Titanium applications benefit from oversized rams and high-torque setups

- Composite machining is supported through both dry and wet cutting modes

When accuracy is paramount, manufacturers choose vertical milling. VMCs are known for high precision and effectiveness in drilling and plunge cutting applications.

The Cost-Efficiency Equation

Vertical mills offer lower upfront costs compared to horizontal configurations. The larger pool of skilled operators reduces operational costs by eliminating extensive training requirements.

The open-front design reduces fixture complexity compared to horizontal setups. Operators can secure raw materials and inspect finished features without removing enclosure panels, significantly cutting setup times per batch.

This accessibility matters when you’re running multiple jobs daily, and setup efficiency directly impacts throughput.

When Vertical Milling Makes Strategic Sense

Vertical milling fits specific manufacturing scenarios particularly well:

- Parts with fewer planes requiring machining

- Smaller to medium-sized components

- Less geometrically complex shapes

- Jobs primarily worked on a single side

- Production runs where time constraints allow for strategic planning

These aren’t limitations. There are optimal use cases where vertical mills deliver superior value compared to more complex configurations.

Technology Integration Driving Modern Performance

CNC technology advancements are changing vertical milling capabilities. AI-powered tools adapt in real time, and energy-efficient designs help cut operational costs while supporting sustainable fabrication.

Machine learning algorithms analyze spindle load and thermal drift, making automatic adjustments with high precision. This reduces scrap rates in high-precision manufacturing compared to static programming methods.

The growing adoption of Industry 4.0 technologies, including IoT and AI integration, drives demand for CNC vertical machining centers. These systems provide real-time monitoring, predictive maintenance, and production optimization.

Automation Without Complexity

Vertical mills integrate automation more easily than many alternatives. The accessible work envelope and straightforward part loading make them ideal candidates for robotic integration.

Manufacturers can implement lights-out manufacturing for appropriate production runs without the complexity and cost associated with horizontal mill automation. This flexibility matters when production demands shift.

Industry Trends Shaping Vertical Milling Demand

The aerospace and defense industry continues to grow. Air travel demand remains strong, while geopolitical tensions drive increased defense spending across multiple countries.

This creates sustained demand for high-precision, high-speed milling machines capable of handling aluminum, titanium alloys, and composites. The specifications aren’t getting easier. They’re getting stricter.

Five-axis milling machines command significant market share for complex aerospace components. However, vertical three-axis machines remain essential for many defense applications where their precision, accessibility, and cost-effectiveness provide optimal value, particularly for chassis fabrication projects.

The ITAR Compliance Factor

Defense contractors require suppliers who maintain ITAR compliance. This regulatory requirement creates a natural barrier to entry and emphasizes the importance of working with established, certified manufacturers.

Vertical milling operations within ITAR-compliant facilities provide defense contractors with the assurance that sensitive components are manufactured within appropriate security and regulatory frameworks.

Our Approach to Vertical Milling at NAMF

We’ve operated in the defense and aerospace sectors since 1979. Our vertical milling services support both our Fairfield, NJ, and Ronkonkoma, NY facilities, providing redundancy and scalability for client projects.

Our vertical machining centers meet the precision requirements defense and aerospace applications demand. We maintain the certifications your contracts require, including AS9100D and NADCAP accreditation.

Integrated Manufacturing Capabilities

We offer vertical milling as part of complete, turnkey solutions. This means we control each manufacturing step, from initial machining through dip brazing, painting, and chemical film finishing. You work with a single point of contact for your components. This saves time finding multiple suppliers and ensures consistency across your production requirements for metal fabrication needs.

Our manufacturing plant in Fairfield provides room for growth as your production needs expand. We’ve invested in the capacity to scale with your programs.

Engineering Support for Manufacturability

We provide collaborative engineering support to refine designs for manufacturability, durability, and performance. This happens before production begins, helping you optimize components and avoid costly revisions. Our engineering team understands DFM principles and works within the constraints of defense and aerospace specifications. We help you balance design intent with manufacturing reality.

Looking Forward: Vertical Milling’s Role in Modern Manufacturing

The vertical milling market’s steady growth reflects its continued relevance in precision manufacturing. As reshoring accelerates and defense spending increases, demand for proven machining capabilities will grow alongside newer technologies.

Vertical mills aren’t being replaced. They’re being enhanced through CNC integration, automation, and real-time monitoring capabilities that improve precision and efficiency.

For defense and aerospace manufacturers, the question isn’t whether vertical milling remains relevant. The question is whether your manufacturing partner has the capabilities, certifications, and capacity to meet your specifications on time.

We’ve built our business around answering that question affirmatively for over four decades.

If you need precision vertical milling for defense or aerospace components, we can help. Contact us to discuss your project requirements and how our integrated manufacturing approach can streamline your supply chain.

Ready to Partner with a Proven Vertical Milling Expert?

NAMF delivers precision vertical milling services with full ITAR compliance and AS9100D certification. Contact us to discuss how our integrated approach can streamline your defense or aerospace project.