Table of Contents

At New Age Metal Fabricating, we can do practically anything with our custom machining services, including stainless steel laser cutting. Laser cutting turns sheets of stainless steel into any size or shape, making the most of the material to pass cost savings down the supply line.

How Laser Cutting Works

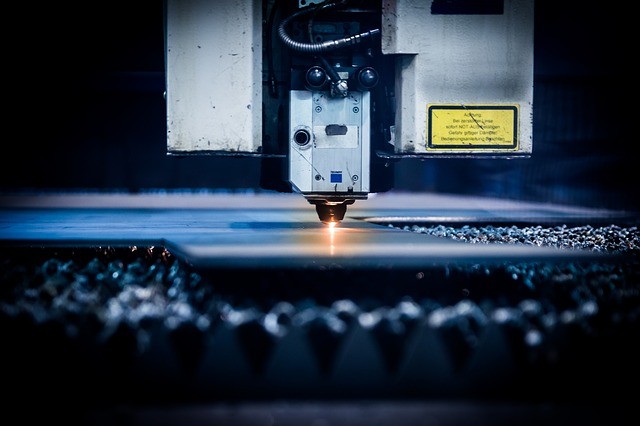

Stainless steel laser cutting technology works by carefully controlling the output of a high powered laser. The cutter itself is typically operated via computer numerical control, which directs how the laser beam is generated and how it is moved. The highly focused beam is directed at the stainless steel material, which ‘cuts’ through it by melting, burning, or vaporizing.

Laser cutting is a non-contact process, which means that the beam does not ever come into physical contact with the material. It’s the heat of the laser that does the work, ensuring that there is less wear and tear on both the laser cutter, and the stainless steel.

Cutting is one of the major steps of any manufacturing and fabrication product, and with the advent of laser cutting technology, this step is happening faster and more accurately even as speed increases. The integrity and quality of finished products relies on precision at initial stages like the cutting phase, which is why we use lasers to do this important work.

Why Choose Stainless Steel Laser Cutting

There are many advantages to stainless steel laser cutting versus mechanical cutting.

First, laser cutting is highly precise. It is generally computer controlled, which means that there is little to no room for human error, so your product turns out exactly as designed. It is also highly precise in that a laser remains as sharp and focused on its millionth cut as it was fresh out of the package, whereas a mechanical cutter will degrade over time. Stainless steel laser cutting can even be more precise than plasma cutting.

For sensitive products laser cutting is ideal as it is a hands-off approach. There is no cutting edge to be contaminated or to contaminate the material, and the stainless steel itself is handled far less than it would be with a mechanical cutting device. You do not need to worry about warping or other heat-related impacts, as the heat area of a laser cutter is very small, effectively cutting without deforming the material.

Stainless steel laser cutting is quick, and operators can switch quickly between tasks so your time is used to its full advantage. This saves your business money without impacting the quality of our work and your end product. For the aerospace industry and other applications in which many duplicate products need to be cut, the speed and precision of laser cutting ensures that design replicas are exact, without slowing down production.

Your Laser Cutting Quote

New Age Metal Fabricating uses a TruLaser 2030 4 kW Fiber-Optic laser, which can cut 5052, 6061 aluminum alloys, stainless steel, copper, and brass. Fiber lasers use an optical fiber as the active medium, versus a gas laser or crystal laser. The fiber laser is extremely stable compared to other types which are more sensitive to movement, as fiber lasers generate the beam on the inside of the fiber. This adds durability to the laser cutting machine itself, which means your product won’t get held up by an accidental bump of the machine.

Our fiber laser cutter is also ideal for your projects as fiber lasers provide straight, strong, ultra-focused beams, which can be adjusted down to a tiny laser dot that offers huge benefits when it comes to precision. Fiber laser cutters use nearly all of the input they receive and come with low maintenance costs, so we can make the most of this machine and pass that efficiency and cost-effectiveness onto our clients in the form of more affordable services.

This is a powerful, fast machine that offers long term reliability. As a result, you can count on us to handle your project without any issues, delivering the parts and products you need as quickly as possible. Our laser cutter can handle thin sheet metal particularly well, making very precise cuts at great speed. Thick sheet metal is not a problem, as the machine can handle it with its precise engineering.

Whatever your end goal is for our laser cutting services, we will make it happen. We are happy to discuss the details of your stainless steel laser cutting project with you to provide you with an accurate and comprehensive estimate.

Contact us for an online quote today. You can also get in touch with New Age Metal Fabricating at 973.227.9107 or in**@**mf.com, or connect with New Age Precision Manufacturing at 631.471.4000 or in**@**pm.com.