Table of Contents

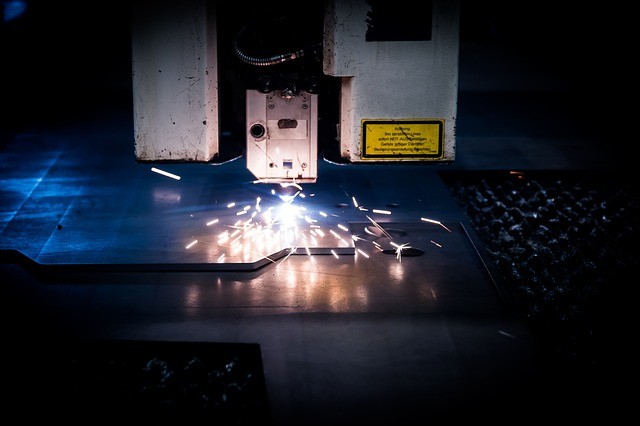

Our Laser Metal Cutting Service

When developing and manufacturing parts and products, it is important that they are cut with precision and to the highest quality. Often times the safety of consumers depends on products made to only the highest of standards. There are many options a full-service manufacturing company might offer, such as plasma cutting, punching, and waterjet cutting. However, laser metal cutting has evolved as the state-of-the-art technology when it comes to metal cutting. Let’s take a look at the process and benefits of using laser metal cutting services.

What is Laser Metal Cutting?

The method of laser metal cutting is exactly as the name implies. It is the use of a high powered laser to precisely cut through, bore, and etch a variety of metals. Due to the nature of the process, plastic and wood are not suitable for laser cutting. Plastics have a tendency to melt and wood may burn. This not only presents a hazard in the work area but compromises the integrity of the material. Metals are best suited for this process. Some metals can be etched and cut, while others are only suitable for either one or the other.

There are three main types of laser cutting used by industries today:

- Carbon dioxide laser cutting – This type of laser cutting works best for engraving, boring, and engraving metals.

- Neodymium – This type of laser cutting is used for high power boring and engraving.

- Neodymium YAG – Although this is similar to Neodymium, this method is great for welding.

Another type of laser cutting is called laser microjet. This less commonly used laser metal cutting service utilizes a water-jet along with a pulsed laser beam to cut the metal. This method is found advantageous because it both cleans and cools the material as it cuts.

The Process of Laser Metal Cutting Service

Laser metal cutting service uses a single color and wavelength of high-intensity light. When most people think of a laser beam, they think of the color red, however, laser beams can actually be a variety of colors. The laser beam is focused by special lenses and mirrors. The beam must be precisely focused. The high powered density allows for melting and vaporization of the material. Compressed gas, such as oxygen or nitrogen flows through the nozzle and helps to clean the surface being cut.

Computer software connected to the laser cutting machine allows the user to input specific designs that the laser machine will then carry out. This reduces the chances of human error and inconsistencies and allows for the production of batches. You can also use laser metal cutting to make prototypes as well.

Benefits of Laser Metal Cutting Service

Laser cutting offers a variety of benefits over processes such as plasma cutting. For starters, the beam does not experience any wear and tear during the cutting process. This means you can expect to receive a uniform cut from start to finish, leaving you with a higher quality edge.

Laser cutting service offers more precisions when cutting through appropriate materials. Save on money by not having to replace blades every so often to ensure quality. This process also uses less energy, which makes it more cost-effective than its alternatives.

Users have the ability to easily create complex shapes and designs without the need for tooling when using laser cutting technology. The ability to use computer software to download designs reduces the time needed to train employees as well as ensures a product made to exact specifications. Unlike traditional cutting methods, laser cutting doesn’t cause as much workpiece contamination.

Common Industries Who Use Laser Metal Cutting Service

Although laser metal cutting service is used across a variety of industries, aerospace and defense are the two most common industries that use laser metal cutting. Both of these industries require parts and products to be made of the highest quality and utmost precision. In many cases, it is a matter of life and death when it comes to aerospace and military products. Products in both of these industries must be able to withstand the harshest conditions.

As laser metal cutting gains momentum it has become popular with small businesses, hobbyists, and schools. This is in large part due to the quality of the product resulting from laser metal cutting as well as the versatility of laser cutting.

Leaders in Laser Metal Cutting Service

New Age Metal Fabrication is the leader in laser metal cutting. Whether you know exactly what you are looking for or need a little help realizing your vision, we can help. Our team is specially trained in fabrication across a variety of industries around the world. Whether you need fabrication, cutting services, or dip brazing services just to name a few, we deliver the highest quality parts and products to your exact specifications. Contact us today for more information on how we can help you fabricate the parts needed for your products.